Aluminum alloy anti-crushing extrusion connection equipment and connection method

A technology for connecting equipment and aluminum alloys, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of connection costs. Meet environmental protection requirements and other issues, achieve the effect of wide application range, strong processing adaptability and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

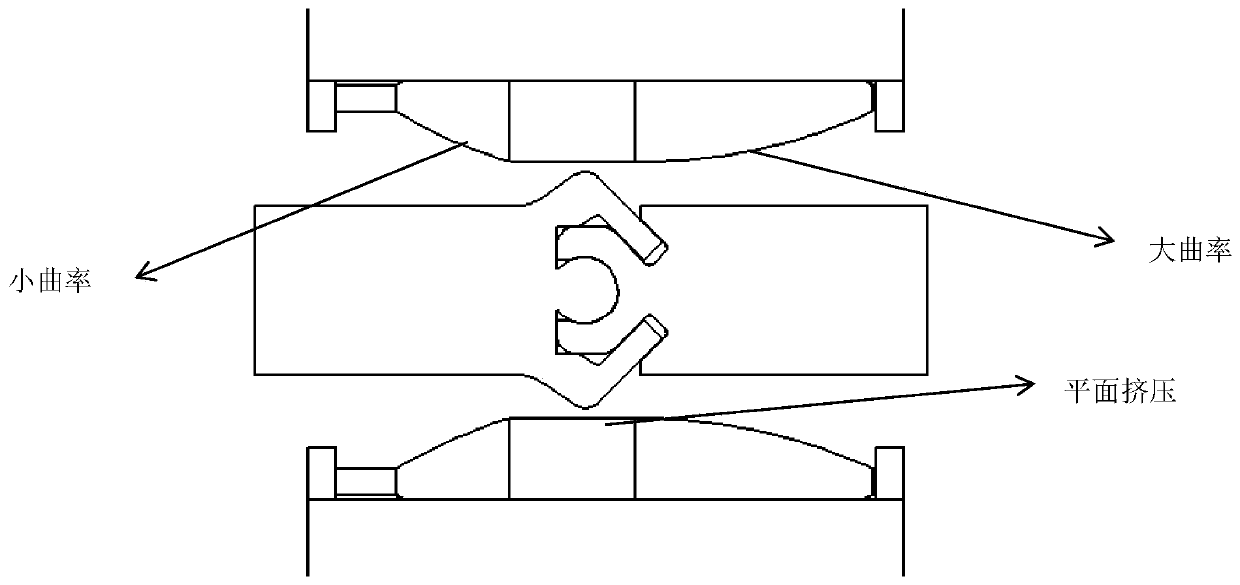

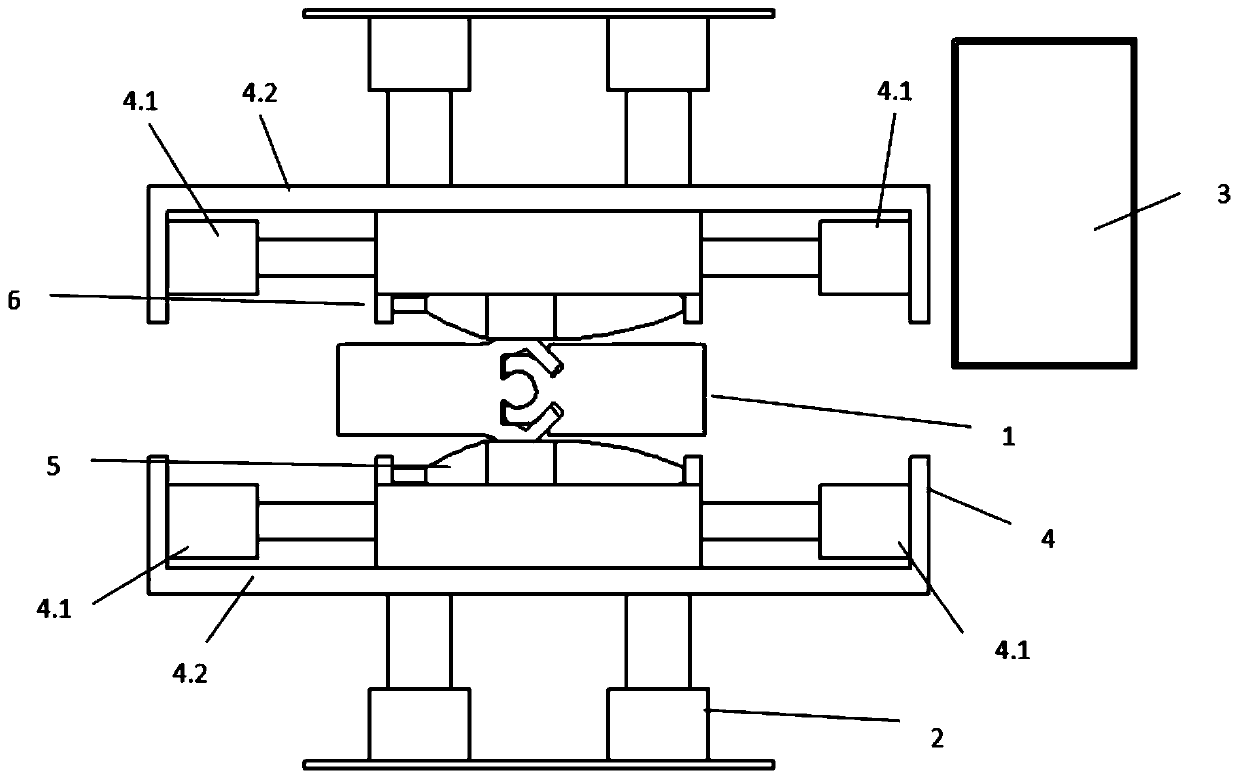

[0039] Attached below Figure 1-6 , the specific implementation of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific implementation.

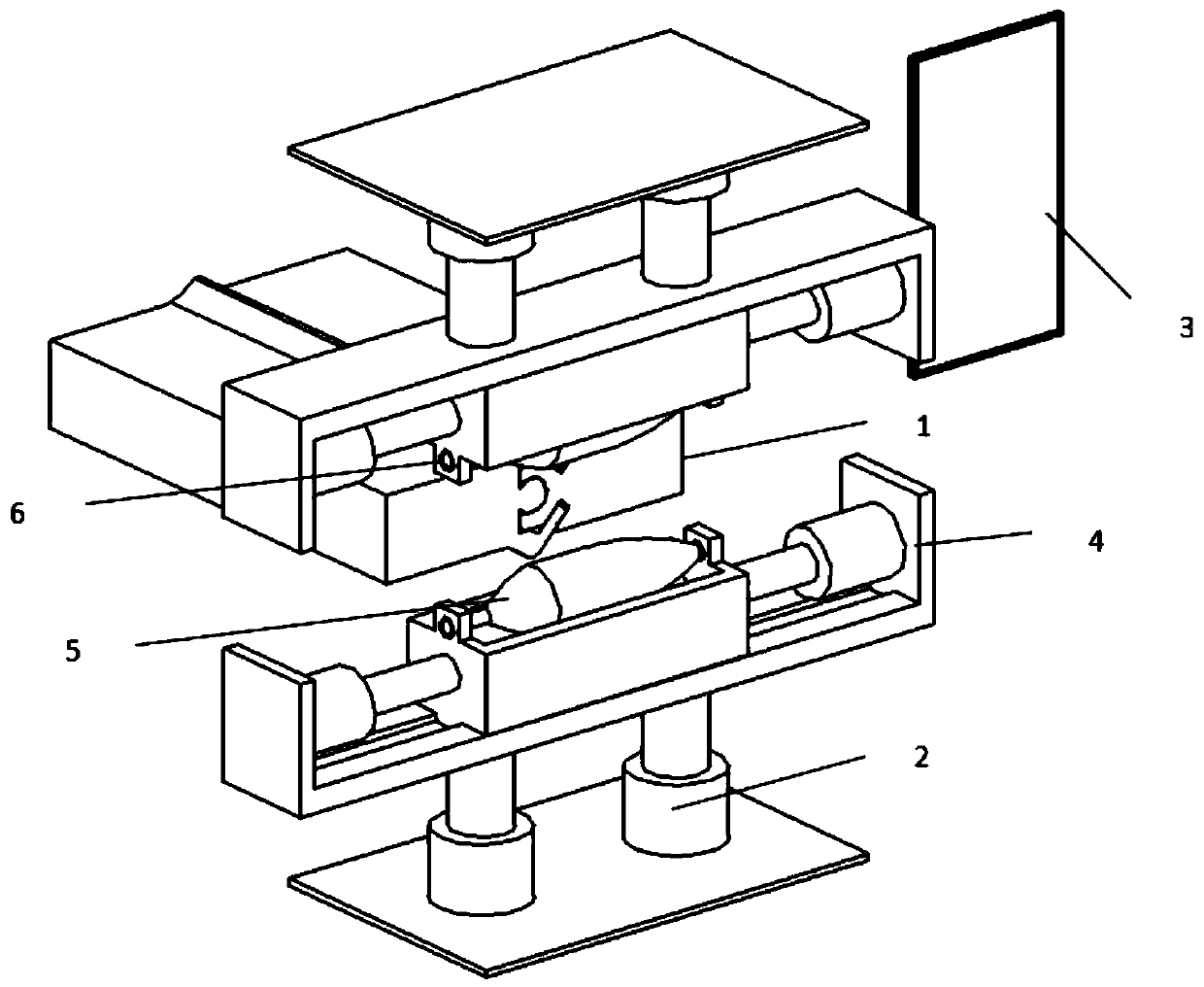

[0040] Such as figure 1 As shown, this embodiment provides an aluminum alloy anti-crushing connection device, which includes a hydraulic press 2, a controller 3, a hydraulic moving track 4, a rolling cutter 5, and a sensor 6;

[0041] Among them, the controller 3 is responsible for signal processing of the connected equipment and controlling equipment components to complete specified functions;

[0042] The hydraulic press 2 is responsible for completing the specified amount of extrusion of the aluminum alloy material 1 input by the controller 3;

[0043] The hydraulic moving track 4 is responsible for completing the lateral movement of the rolling tool 5 according to the stress received by the controller 3 at different times and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com