A special-shaped sprue cup for high-temperature alloy casting and its forming method

A high-temperature alloy and sprue cup technology, which is applied to casting molding equipment, cores, casting molds, etc., can solve the problems of mold shell damage, difficult coating mechanization operation, etc., to improve quality, reduce splash and turbulence, and improve Effect of pour quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

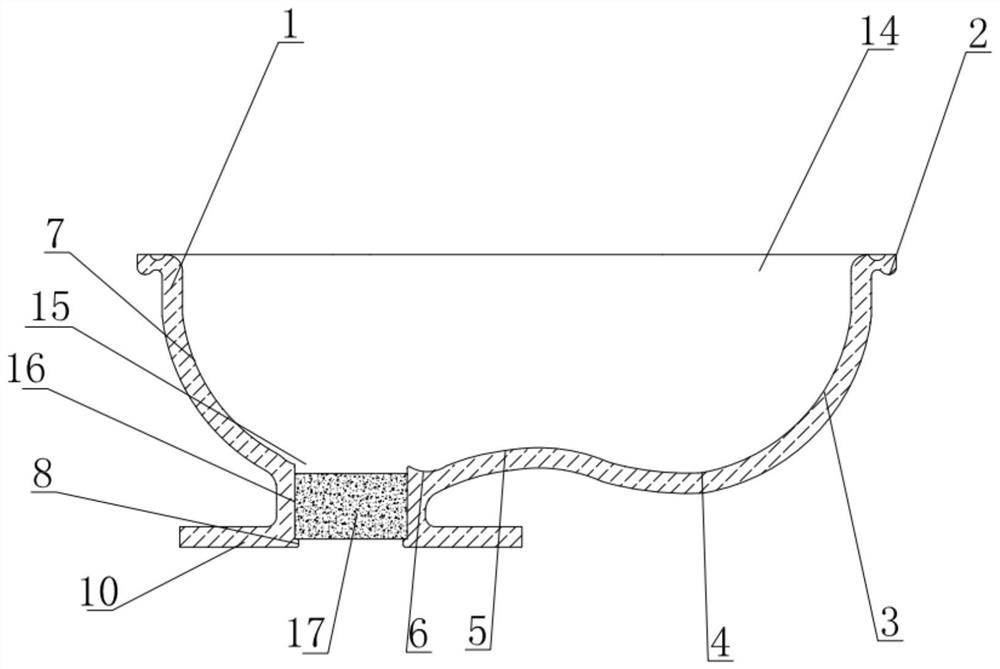

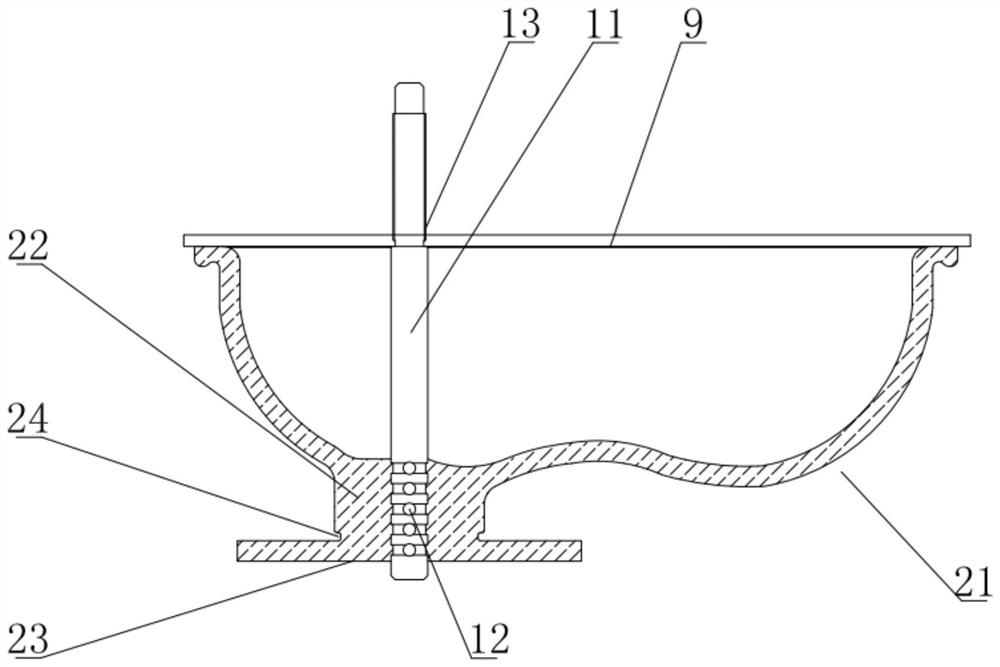

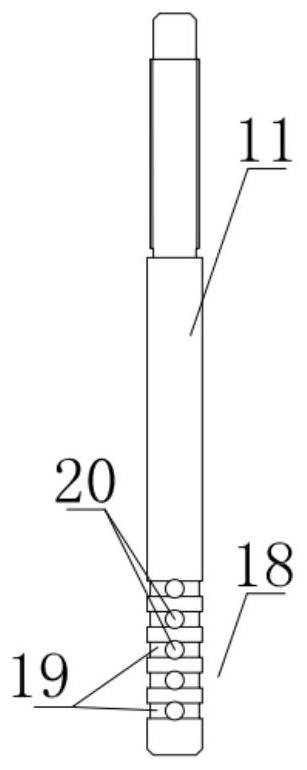

[0031] like figure 1 and Figure 4 As shown, a special-shaped pouring cup for high-temperature alloy casting includes a pouring cup body 1, a pouring cup inlet 14, a pouring cup outlet 15 and a support plate 10. The outside of the special-shaped pouring cup is in the shape of a peanut shell, The top peripheral ring of the sprue cup body 1 is provided with an eversion edge 2 , and the sprue cup body 1 includes a first buffer arc area 3 , a first slag blocking area 4 , and a second buffer area that are connected in sequence and formed integrally. The arc area 5, the second slag blocking area 6 and the third buffer arc area 7, the first buffer arc area 3 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com