Preparation device and preparation method of composite particles for electromagnetic rheological polishing

A technology for composite particles and preparation devices, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as inability to guarantee processing uniformity, inability to effectively capture, restrict abrasive particles, and accelerate particle wear, so as to reduce the matching of electric field and magnetic field Difficulty of regulation, reduced influence of particle interactions, possible effect of reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

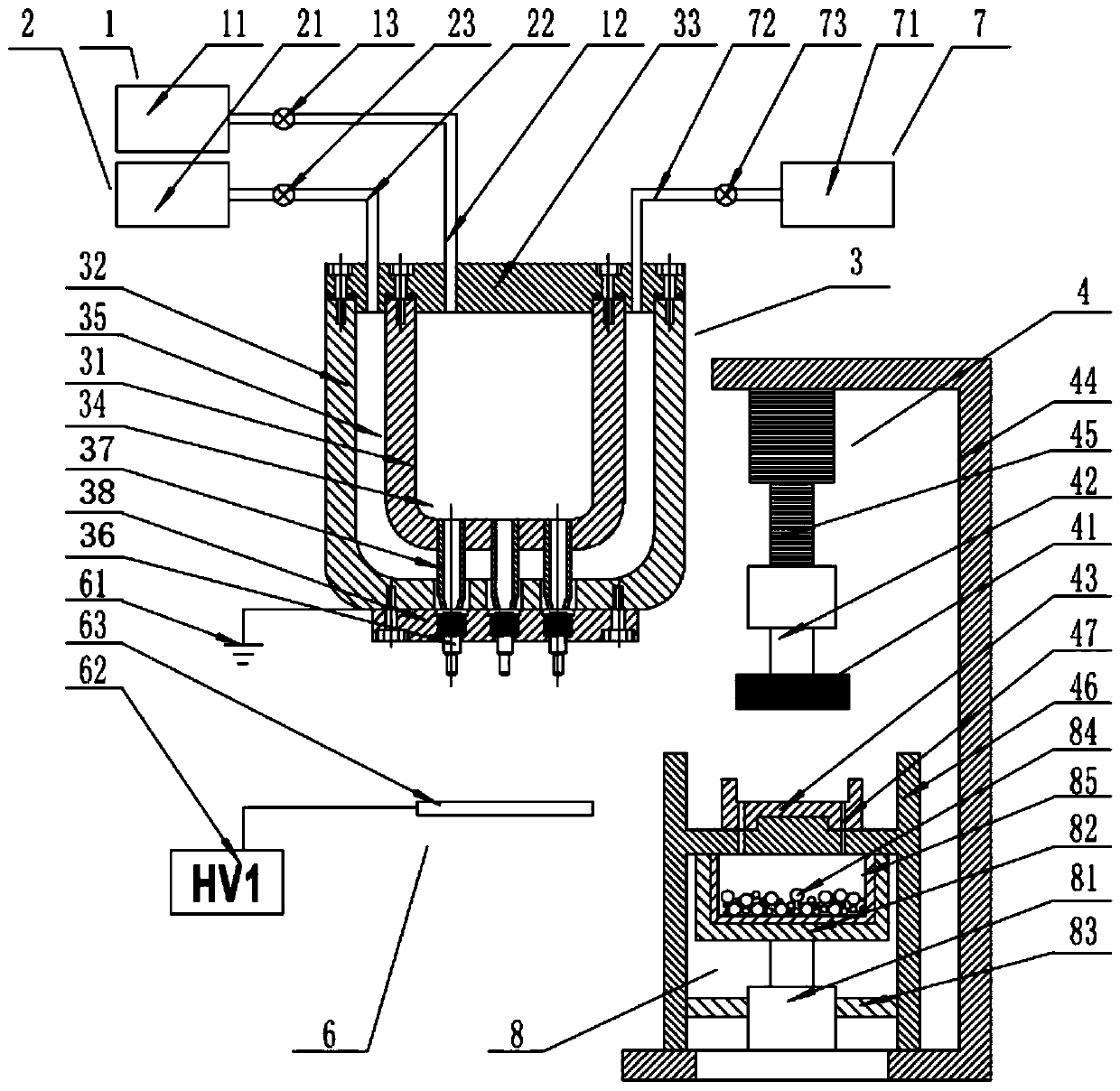

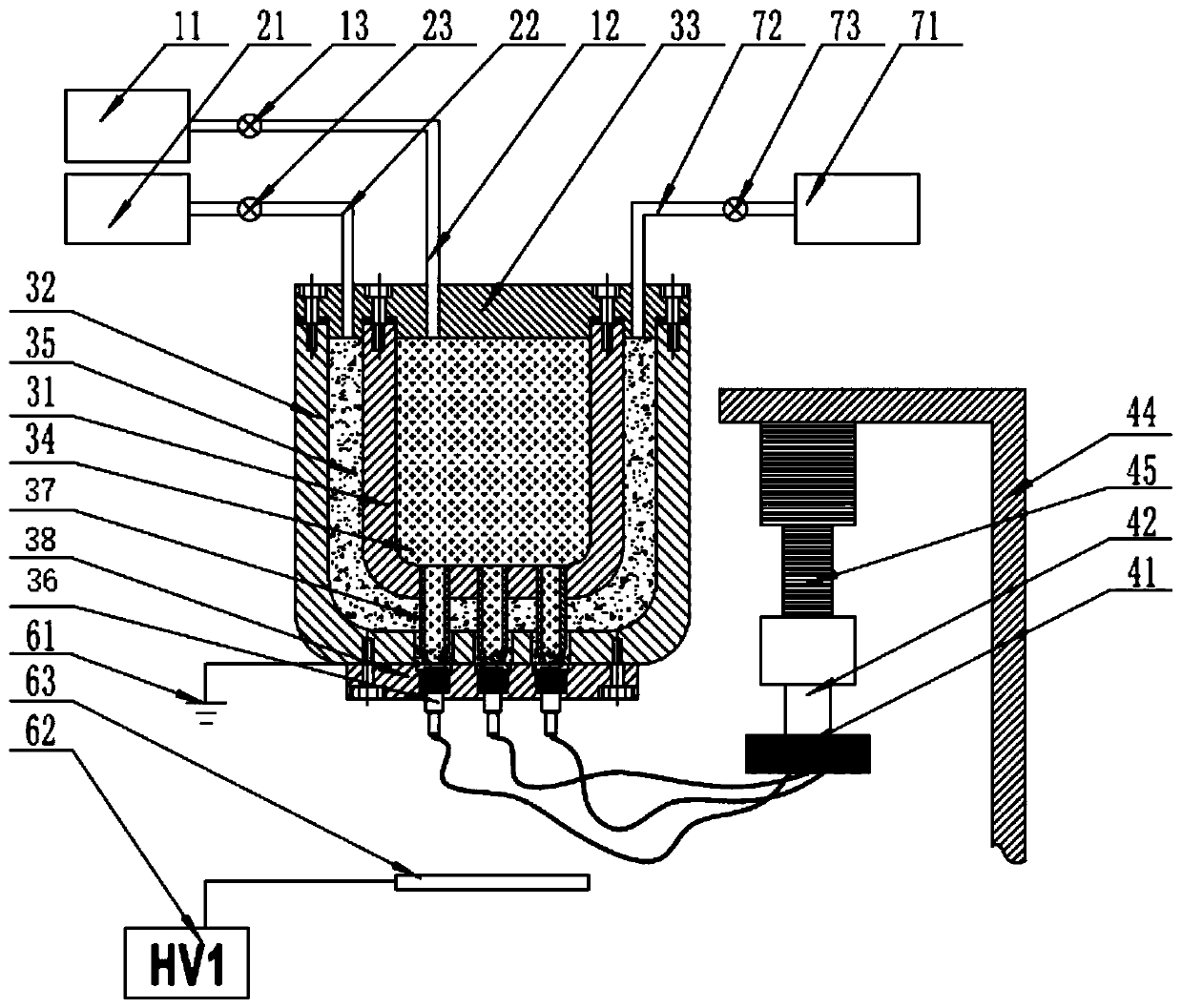

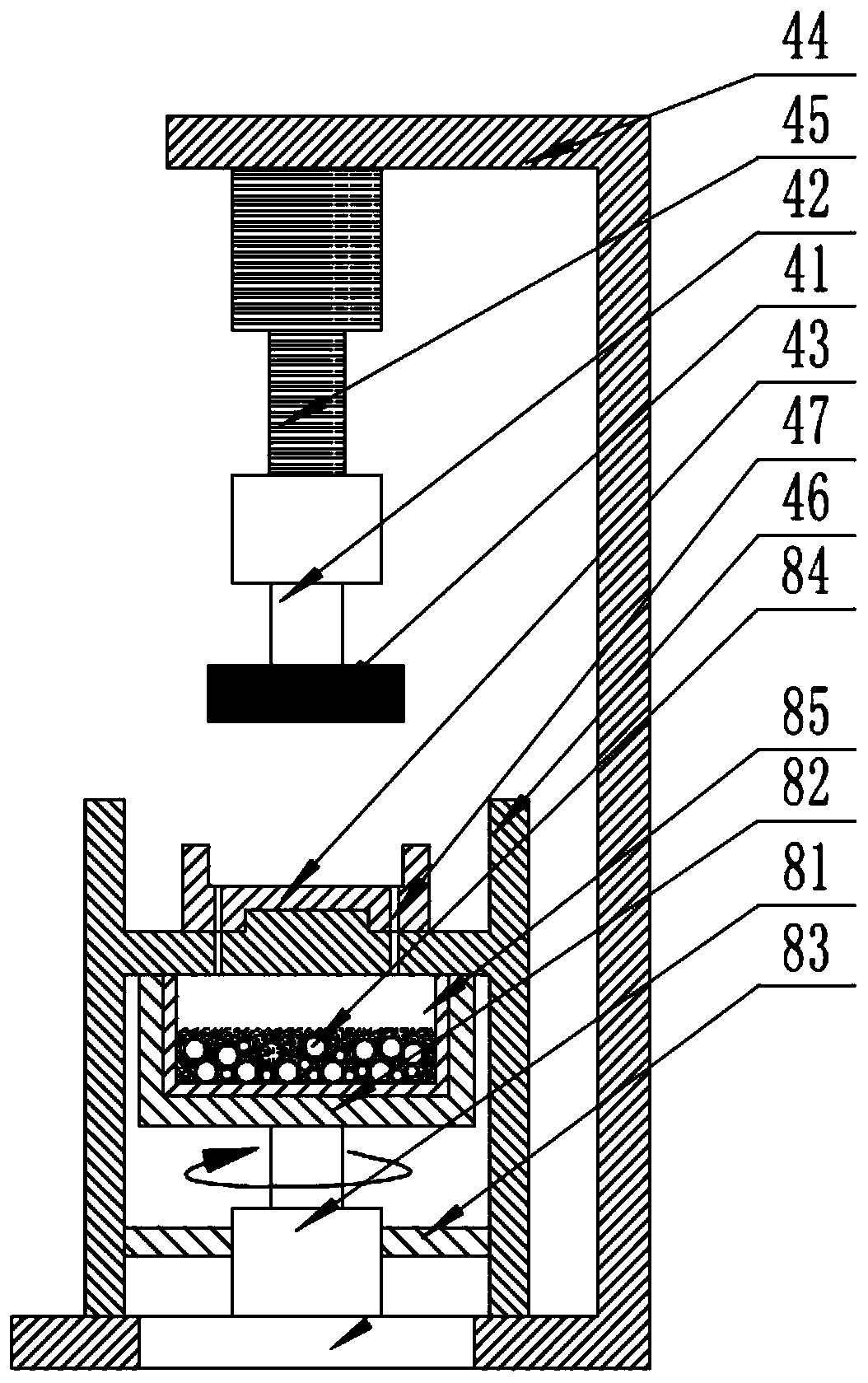

[0038] Such as Figure 1 to Figure 6 Shown is the embodiment of the preparation device of the composite particles 9 for electromagnetic rheological polishing of the present invention, including an electrospinning assembly, a crushing assembly 4 and a screening assembly 5 for screening charged particles, composite particles 9 and uncharged particles, The electrospinning assembly includes a magnetic particle 91 supply assembly 1, a polymer 92 supply assembly 2, and a spinning assembly 3 that is spun to obtain magnetic composite nanofibers. The polymer 92 contains abrasive particles 93, and the polymer 92 is wrapped in a magnetic Particle 91 periphery, spinning assembly 3 communicates with magnetic particle 91 supply assembly 1, polymer 92 supply assembly 2, pulverization assembly 4 comprises electromagnet briquetting 41, first drive motor 42 and is located at electromagnet briquetting 41 just below The grinding disc 43 and the electromagnet briquetting block 41 are connected to ...

Embodiment 2

[0052] This example is an example of using the preparation device of the composite particles 9 for electromagnetic rheological polishing in Example 1 to be applied to the preparation method of the composite particles 9 for electro-rheological polishing, including the following steps:

[0053] S10. Open the gas supply assembly 7, ventilate the inside of the liquid distribution pipe 37 and the nozzle 36, and ensure that the liquid distribution pipe 37 and the nozzle 36 are not blocked;

[0054] S20. Add the first mixed liquid after the magnetic particles 91 are mixed with the dispersant and the base liquid to the magnetic particle 91 supply component 1, and add the second mixed liquid of the abrasive mixed polymer 92 to the polymer 92 supply component 2;

[0055] S30. Adjust the distance between the first electrode plate 63 and the nozzle 36, start the first voltage supply unit 62 to provide voltage, and at the same time energize the electromagnet pressing block 41. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com