Microbial paraffin removal and inhibition method for paraffin-containing oil well

A technology for removing wax and preventing microorganisms. It is used in cleaning equipment, earth-moving drilling, wellbore/well components, etc. It can solve the problems of inability to adapt to temperature changes, affecting the effect of wax removal and prevention, and save hot flushing times and on-site The effect of good test effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] High wax oil well C in a block of Shengli Oilfield 2 , the reservoir temperature is 72°C, the wax content is 35.0%, the formation water salinity is 25635mg / L, and the daily fluid production of the oil well is 60m 3 , before the test, the water cut was 93.5%, the well depth was 1500m, the bottom hole temperature was 85°C, the wellhead temperature was 25°C, the hot washing cycle was 20 days, and the average annual hot washing time of a single well was 18 wells. Utilize method of the present invention to implement field test in this high waxy oil well, concrete implementation steps are as follows:

[0041] (1) Screening of test wells

[0042] Test well C 2The reservoir temperature is 72°C, the formation water salinity is 25635mg / L, the water cut is 93.5%, and the wax content is 35.0%. The present invention can be practiced in the well that meets the screening criteria of the present invention.

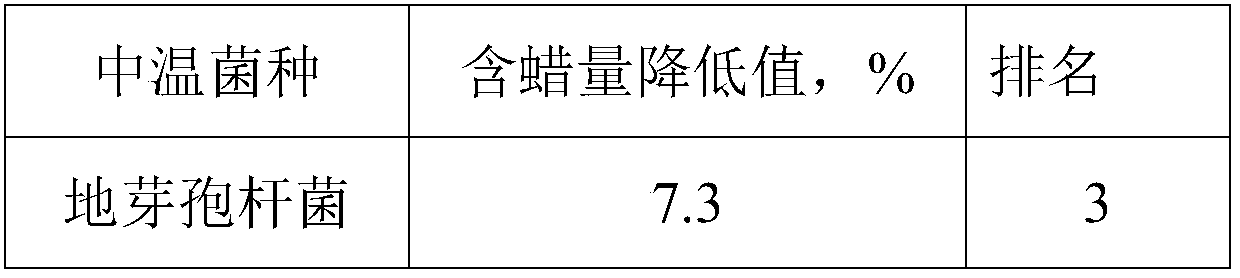

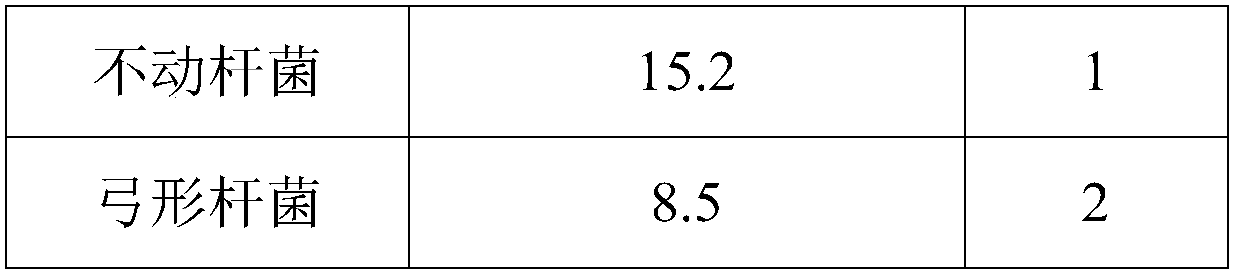

[0043] (2) Determination of the temperature range of low, medium and high ...

Embodiment 2

[0066] High wax oil well C in a block of Shengli Oilfield 5 , the reservoir temperature is 82°C, the wax content is 37.3%, the formation water salinity is 21232mg / L, and the daily fluid production of the oil well is 100m 3 , before the test, the water cut was 94.2%, the well depth was 1650m, the bottom hole temperature was 91°C, the wellhead temperature was 25°C, the hot washing cycle was 30 days, and the single well was hot washed 12 times per year on average. Utilize method of the present invention to implement field test in this high waxy oil well, concrete implementation steps are as follows:

[0067] (1) Screening of test wells

[0068] Test well C 5 The reservoir temperature is 82°C, the formation water salinity is 21232mg / L, the water content is 94.2%, and the wax content is 37.3%. The present invention can be practiced in the well that meets the screening criteria of the present invention.

[0069] (2) Determination of the temperature range of low, medium and high ...

Embodiment 3

[0093] High wax oil well C in a block of Shengli Oilfield 8 , the reservoir temperature is 65°C, the wax content is 35.7%, the formation water salinity is 45268mg / L, and the daily fluid production of the oil well is 40m 3 , before the test, the water cut was 93.2%, the well depth was 1250m, the bottom hole temperature was 70°C, the wellhead temperature was 25°C, the hot washing cycle was 20 days, and the average annual hot washing time of a single well was 18 wells. Utilize method of the present invention to implement field test in this high waxy oil well, concrete implementation steps are as follows:

[0094] (1) Screening of test wells

[0095] Test well C 8 The reservoir temperature is 65°C, the formation water salinity is 45268mg / L, the water content is 93.2%, and the wax content is 35.7%. The present invention can be practiced in the well that meets the screening criteria of the present invention.

[0096] (2) Determination of the temperature range of low, medium and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com