A new recyclable wax remover and its preparation and recovery method

A recovery method and technology of wax remover, applied in the field of new wax remover and its preparation and recovery, can solve the problems of rising use cost and non-recyclability, and achieve the effects of reducing industrial cost, improving wax removal and preventing effect, and achieving remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

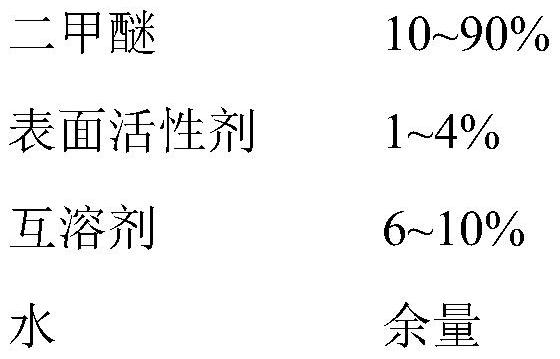

[0030] The main agent is dimethyl ether and water, the surfactant is sodium dodecylbenzenesulfonate and SP80, and the mutual solvent is ethylene glycol monobutyl ether. The proportioning ratio is as follows (by mass percentage):

[0031]

[0032]

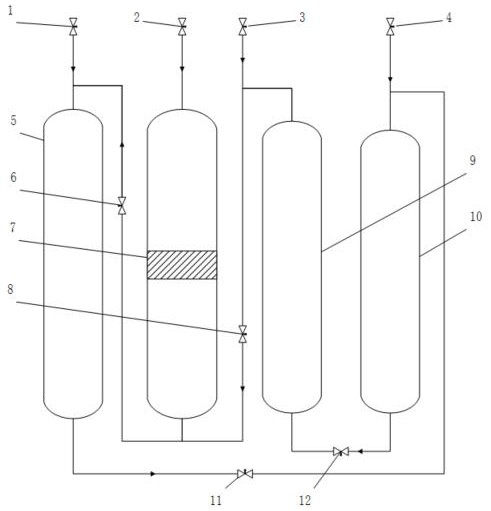

[0033] Preparation method: add 300g of water to the reaction kettle (10), start stirring, then add 10g of sodium dodecylbenzenesulfonate, 180g of ethanol, and 10g of SP80 successively under stirring, and then pass the needle valve (4) to the reaction kettle ( 10) Pressurize the inside to be higher than 0.5Mpa, then add 500g of dimethyl ether into the reaction kettle (10) through the storage tank (5) through the needle valve (11), and continue stirring evenly to obtain the product.

[0034] After testing, at 45°C, the wax melting rate of this product to No. 56 paraffin wax is 0.0487g / min, and the recovery rate of a new type of recyclable wax remover obtained through the recovery operation reaches 83%.

example 2

[0036] The main agent is dimethyl ether and water, the surfactant is isoamyl alcohol and cetyltrimethylammonium chloride, and the mutual solvent is ethanol, and its proportioning ratio is as follows (by mass percentage):

[0037]

[0038] Preparation method: add 300 g of water into the reaction kettle (10), start stirring, and then add 10 g of cetyltrimethylammonium chloride, 80 g of ethanol, and 10 g of isoamyl alcohol in turn under stirring, and then pass through the needle valve (4) Pressurize the reaction kettle (10) to higher than 0.5Mpa, then add 600g of dimethyl ether into the reaction kettle (10) through the storage tank (5) through the needle valve (11), and continue to stir evenly to obtain the product.

[0039] After testing, at 45°C, the wax-melting rate of this product to No. 56 paraffin wax is 0.0437g / min, and the recovery rate of a new recyclable wax remover obtained through the recovery operation reaches 88%.

example 3

[0041] The main agent is dimethyl ether and water, the surfactant is cetyltrimethylammonium chloride and SP80, the mutual solvent is ethylene glycol monobutyl ether, and its proportioning ratio is as follows (by mass percentage):

[0042]

[0043]

[0044] Preparation method: add 220g of water to the reaction kettle (10), start stirring, and then add 10g of cetyltrimethylammonium chloride, 60g of ethanol, and 10g of SP80 in turn under stirring, and then pass the needle valve (4) to the reaction Pressurize the kettle (10) to higher than 0.5Mpa, then add 700g of dimethyl ether into the reaction kettle (10) through the storage tank (5) through the needle valve (11), and continue to stir evenly to obtain the product.

[0045] After testing, at 45°C, the wax melting rate of this product to No. 56 paraffin wax is 0.034g / min, and the recovery rate of a new type of recyclable wax remover obtained through the recovery operation reaches 90%. (The speed above is 40r / min)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com