Fascia gun movement and working method thereof

A fascia gun and movement technology, applied in electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of inconvenient storage and carrying, large product size, poor user experience, etc., and achieve high overall space utilization and compact structure. , the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

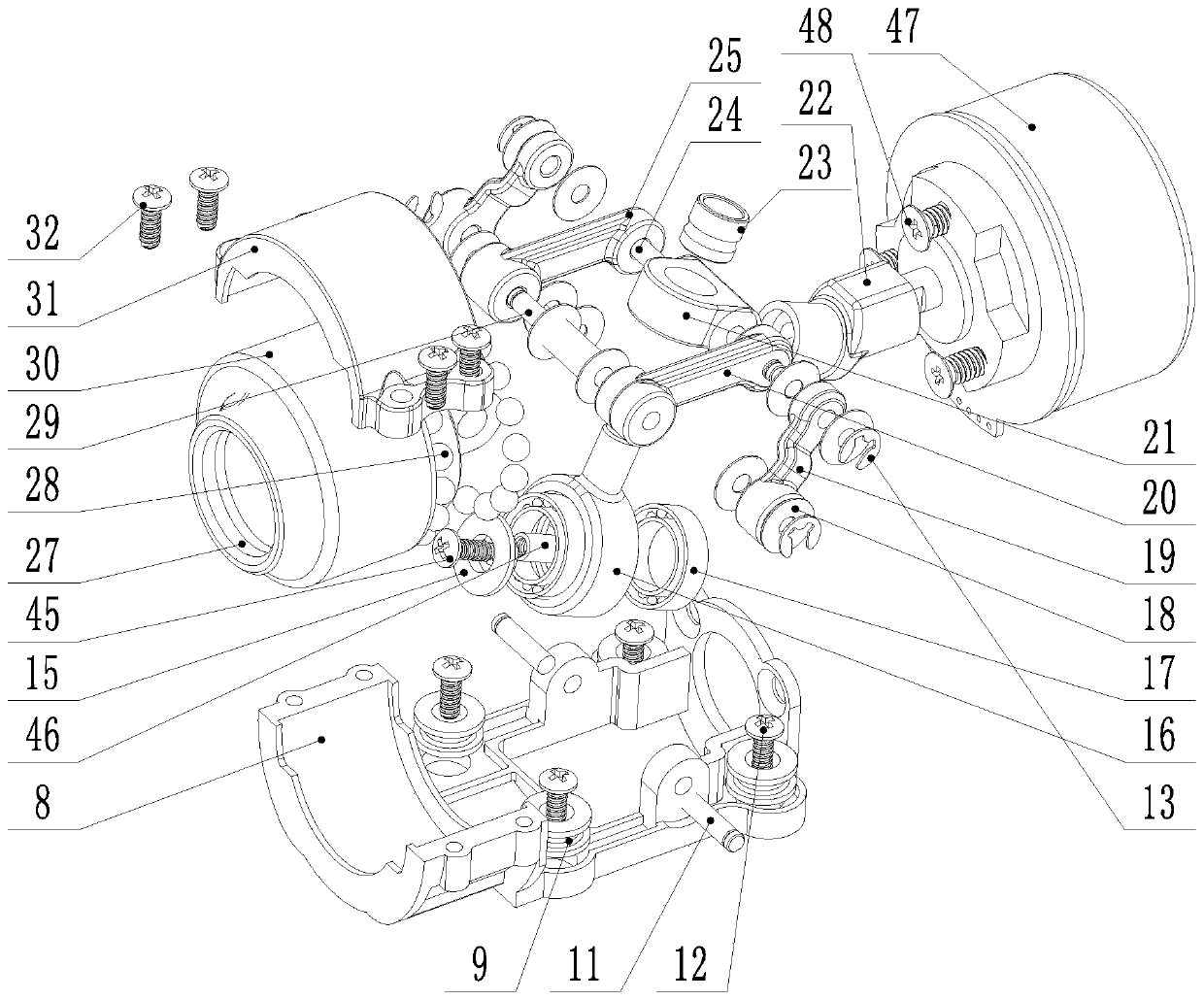

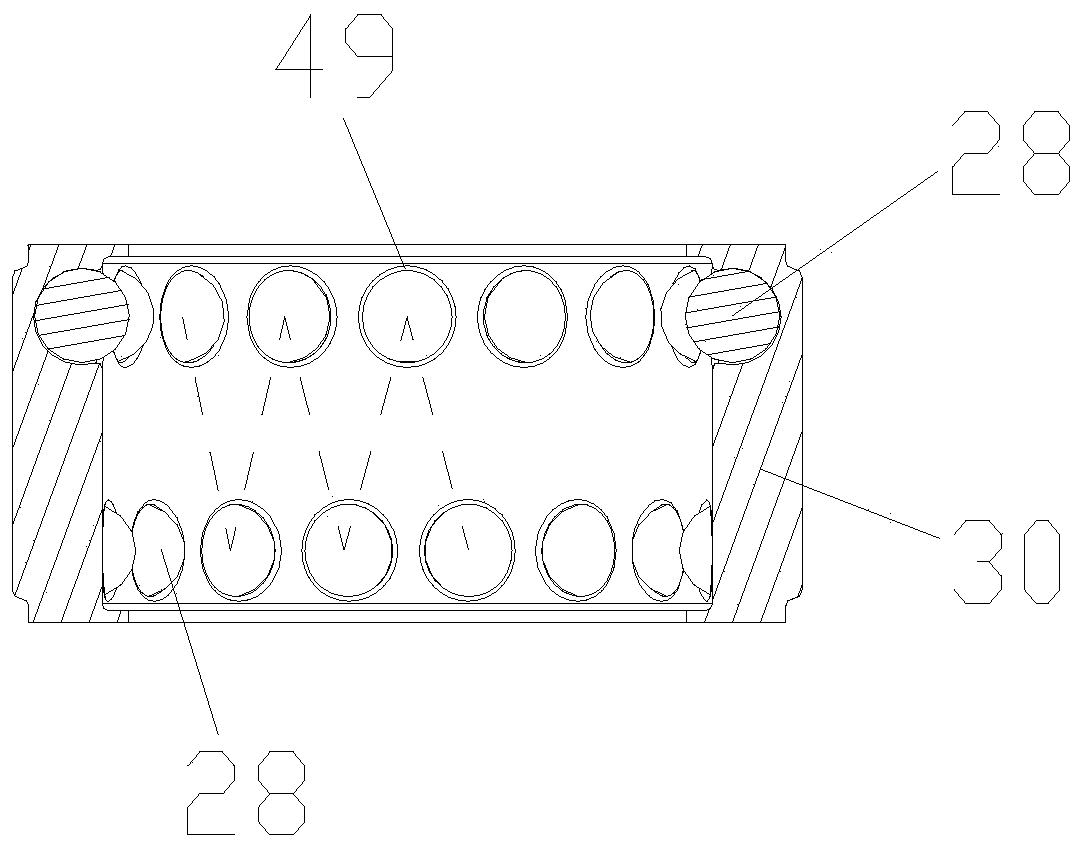

[0020] Such as figure 1 As shown, this embodiment provides a fascia gun movement, including a motor 47, a crank shaft 22, a swing rod 16, a shaft block 21, a swing rod shaft 24, a left connecting rod 20, a right connecting rod 25, and a pulley rotating shaft 29 and the sliding sleeve 27, the horizontal rear end of the crank shaft 22 is fixedly sleeved on the output shaft of the motor 47, the lower end of the swing rod 16 is rotatably sleeved on the inclined front end of the crank shaft 22, the The central hole of the rotating shaft block 21 is rotatably sleeved on the upper end of the swing rod 16, the swing rod shaft 24 is transversely arranged at the rear of the rotating shaft block 21, and the rear ends of the left connecting rod 20 and the right connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com