Motor controller active discharge system and control method

A motor controller and active technology, applied in the control system, motor control, electrical components, etc., can solve the problems of increasing hardware cost, IGBT damage, affecting driving experience, etc., and achieve the effect of reducing risk and delaying the shutdown speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

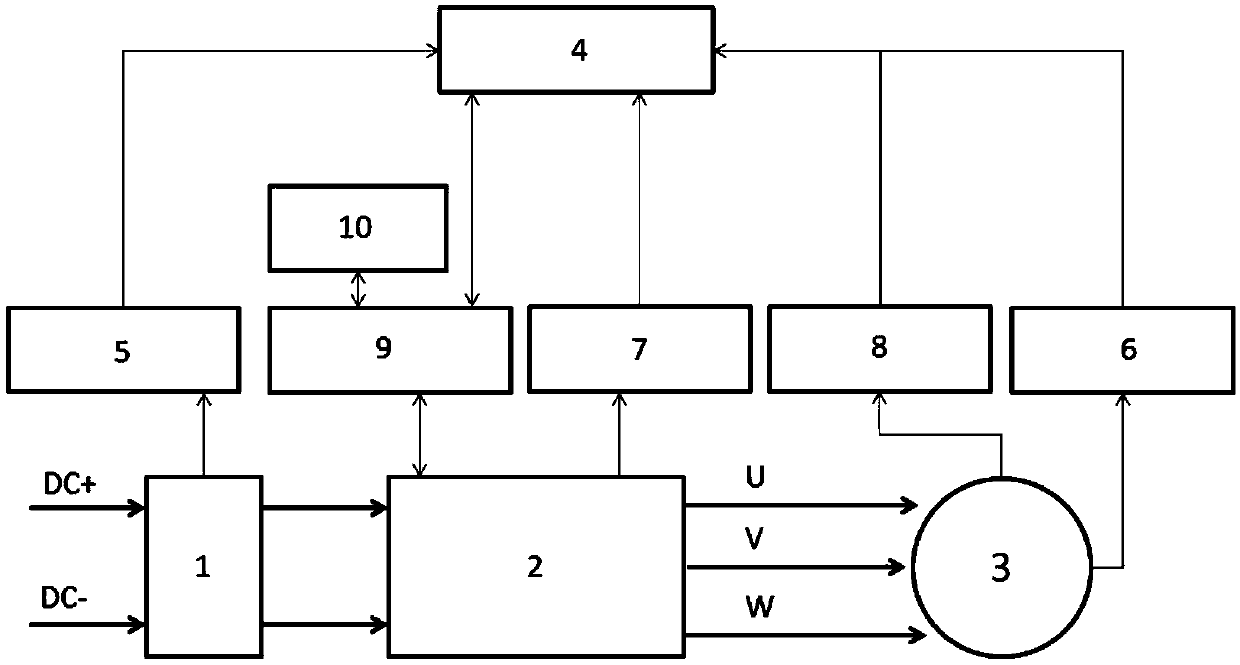

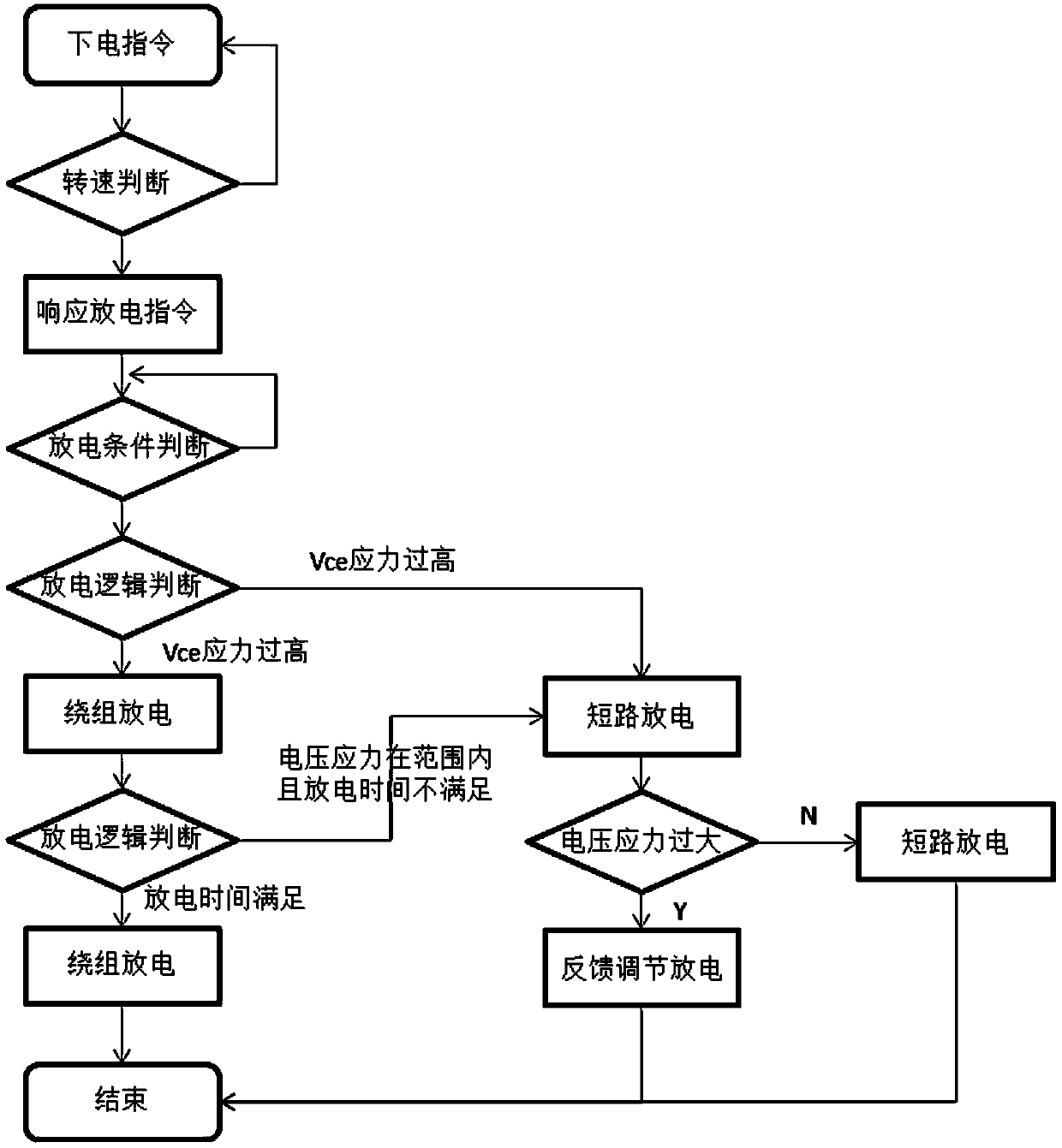

[0023] Such as figure 1 As shown, it is a motor controller active discharge system involved in this embodiment, including: input bus 1, IGBT circuit 2, drive unit 3, motor 4 and control unit 5, wherein: input bus 1, IGBT circuit 2, motor 3 and the control unit 5 are connected in series to form a loop, and the input end and the output end of the drive circuit 3 are respectively connected with the control unit 5 and the IGBT circuit 2 .

[0024] The IGBT circuit 2 is a three-phase bridge inverter circuit, comprising: three bridge arms 10 connected in parallel, each bridge arm 10 is connected in series with two IGBT single tubes a to f, wherein: three bridge arms 10 The central point of the U, V, and W terminals are respectively connected to the three-phase alternating current port of the motor 4.

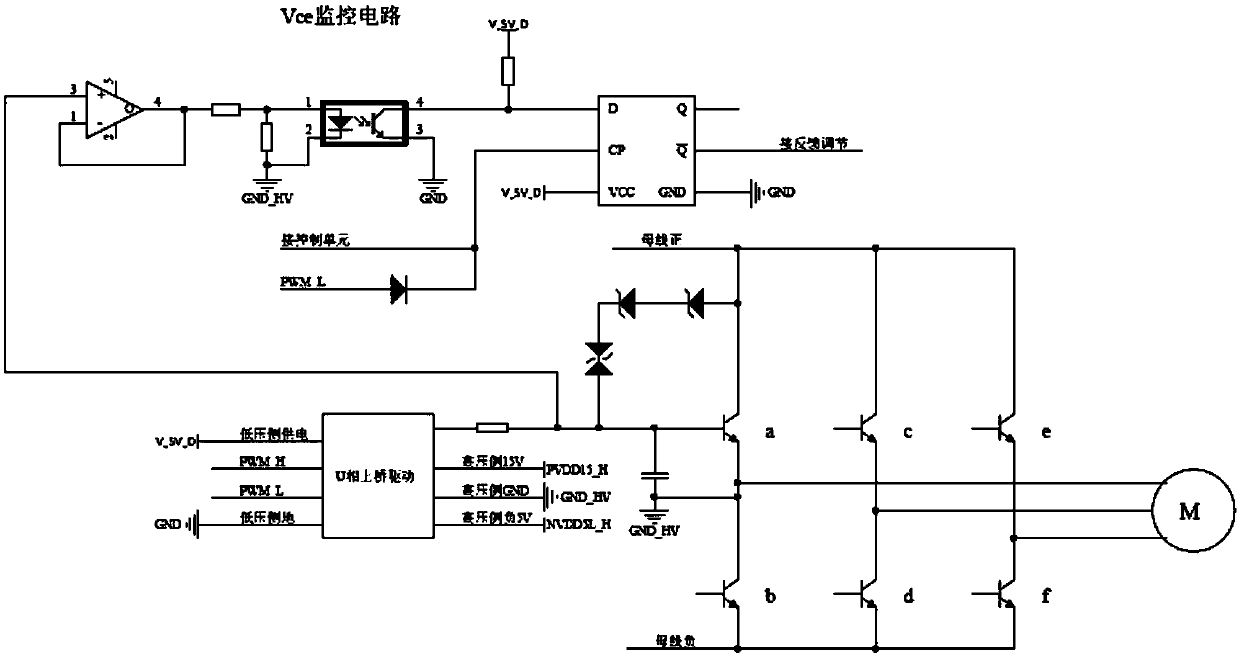

[0025] The driving circuit includes: six sets of identical driving components, taking the U-phase upper bridge as an example, the input terminals of the driving chip are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com