Antibacterial pressure-resistant double-layer cream bottle and material preparation method thereof

A double-layer, cream technology, applied in the field of cream bottles, can solve the problems of inconvenient production and assembly of the bottle body and the cover, poor structural design of the inner and outer covers, etc., and achieves the advantages of easy automatic production, feasible preparation method and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

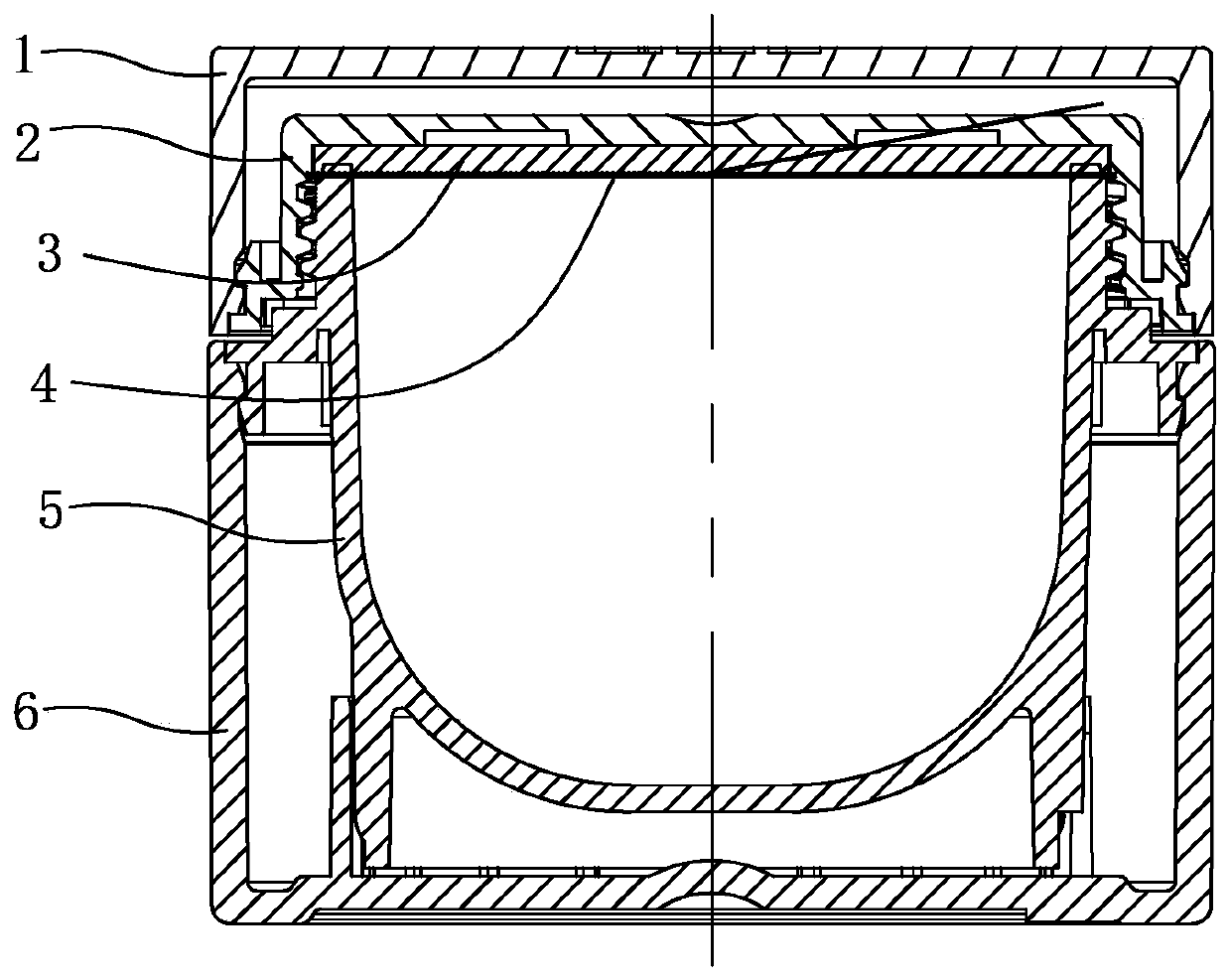

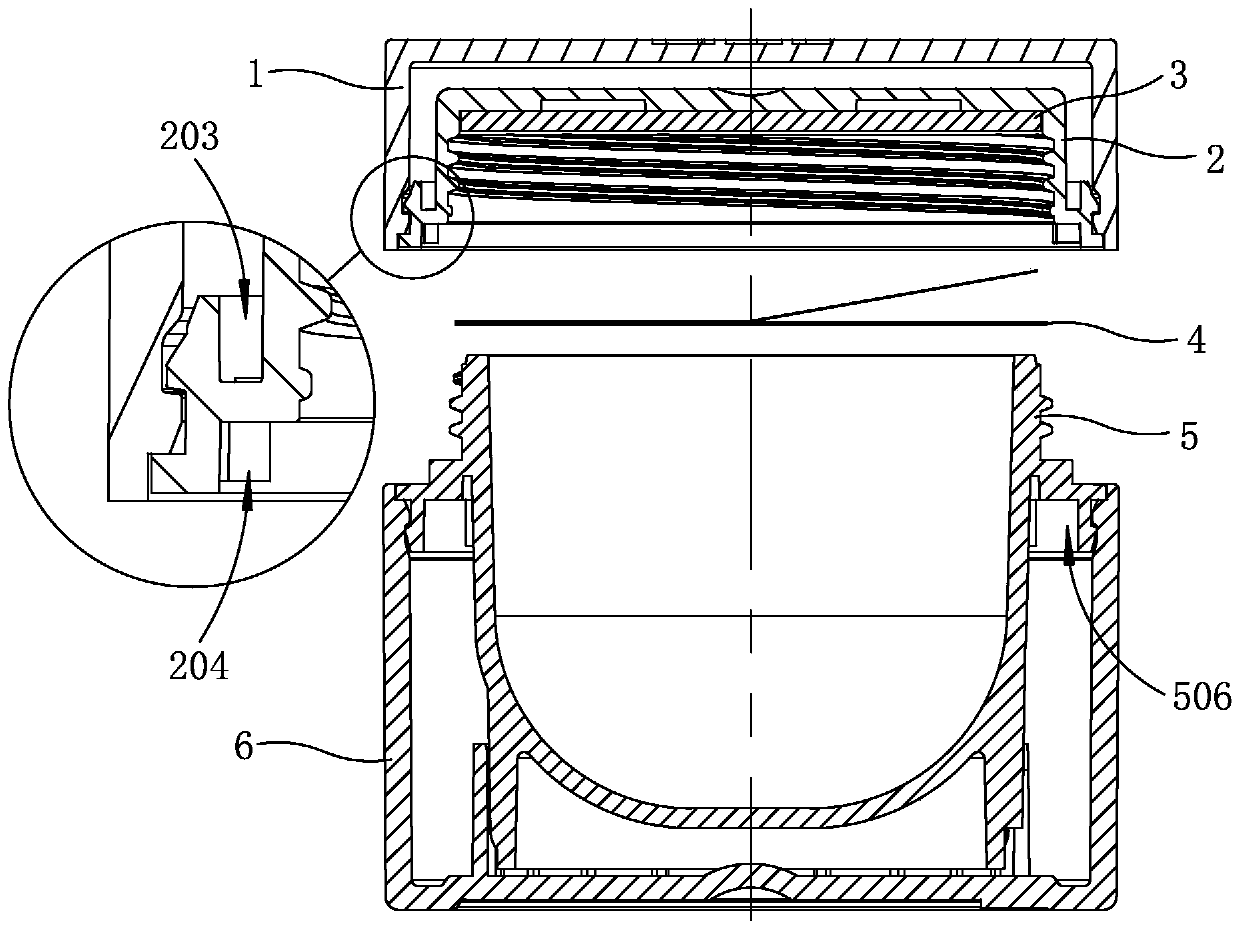

[0024] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. Such as Figure 1-Figure 8 As shown, the cover body of the double-layer cream bottle includes an outer cover 1, an inner cover 2 and a high-foaming adhesive gasket 3, and the bottle body includes an inner bottle 5 and an outer bottle 6, and the bottle mouth 505 of the inner bottle is provided with a thermal sensor. Aluminum foil gasket 4, the inner thread at the inner diameter of the lid mouth of the inner cap is connected with the outer thread at the outer diameter of the mouth of the inner bottle. Its specific structure is as follows: the outer diameter of the inner bottle below the external thread of the inner bottle is provided with a raised ring diameter, the outer diameter of the inner bottle below the ring diameter is provided with a buckle ring 502 with a diameter smaller than the ring diameter, and the inner ring below the buckle ring The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com