Preparation method of GH4169 alloy bars

A GH4169 alloy technology, applied in metal processing equipment, metal extrusion dies, etc., can solve problems such as instability between batches of production, uneven grain size, etc., and achieve consistent deformation conditions at the head and tail of bars and material utilization. High, simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

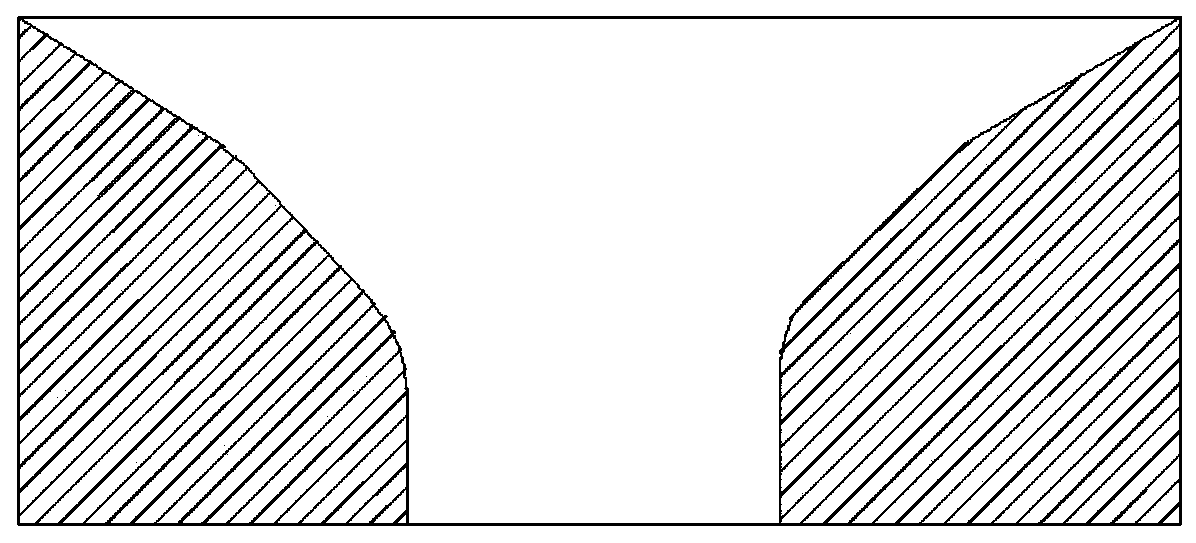

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a GH4169 alloy fine-grained bar stock, comprising the following steps:

[0030] Step 1. Utilize the free forging press to upset the ingot by means of closed upsetting or open forging upsetting. The upsetting deformation temperature is 1110±20°C, and the upsetting deformation is 30-60%;

[0031] In the above step 1, controlling the initial forging temperature at 1110±20°C can ensure that the as-cast structure of the ingot is fully broken, which is conducive to the formation of a uniform structure inside the bar.

[0032] In the above step 1, the upsetting deformation is controlled at 30-60%. On the one hand, it is necessary to ensure that the as-cast structure of the bar is broken. On the other hand, in order to ensure that the extrusion ratio in step 3 is between 3 and 6 , so as to ensure that recrystallization fully occurs inside the bar during the hot extrusion process.

[0033] By controlling the upsetting and the defo...

Embodiment 2

[0048] This embodiment is used to prepare a fine-grained rod with a diameter of φ300mm.

[0049] Step 1: Use the free forging press to use closed upsetting or free forging upsetting The ingot is upset, and the deformation temperature is 1110±10°C. After the homogenized ingot is heated evenly, it is released from the furnace for upsetting, and the upsetting deformation is 43%.

[0050] In the above step 1, controlling the initial forging temperature at 1110±10°C can ensure that the as-cast structure of the ingot is fully broken, which is conducive to the formation of a uniform structure inside the bar.

[0051] In the above step 1, the amount of upsetting deformation is controlled at 43%. On the one hand, it is necessary to ensure that the as-cast structure of the bar is broken; Ensure that recrystallization fully occurs inside the bar during hot extrusion. Step 2: Perform surface machining on the forged blank obtained by upsetting, remove black skin and defects, and select ...

Embodiment 3

[0059] The present embodiment is used for preparing diameter and is φ 300mm fine-grained bar stock, comprises the following steps:

[0060] Step 1: Use the free forging press to perform upsetting by means of closed upsetting or open forging upsetting. The deformation temperature is 1110°C. After the ingot is heated to a uniform temperature, it is out of the furnace for upsetting. The upsetting deformation is 45%.

[0061] In the above step 1, controlling the initial forging temperature at 1110°C can ensure that the as-cast structure of the ingot is fully broken, which is conducive to the formation of a uniform structure inside the bar.

[0062] In the above step 1, the amount of upsetting deformation is controlled at 45%. On the one hand, it is necessary to ensure that the as-cast structure of the bar is broken. On the other hand, in order to ensure that the extrusion ratio is between 4.5 and Fully recrystallized inside the bar during extrusion.

[0063] Step 2: Perform surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com