Building steel pipe auxiliary welding device

A technology for auxiliary welding and construction, which is applied in the field of auxiliary welding devices for steel pipes for construction, and can solve problems such as unfavorable development of infrastructure, complicated and cumbersome operation steps, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

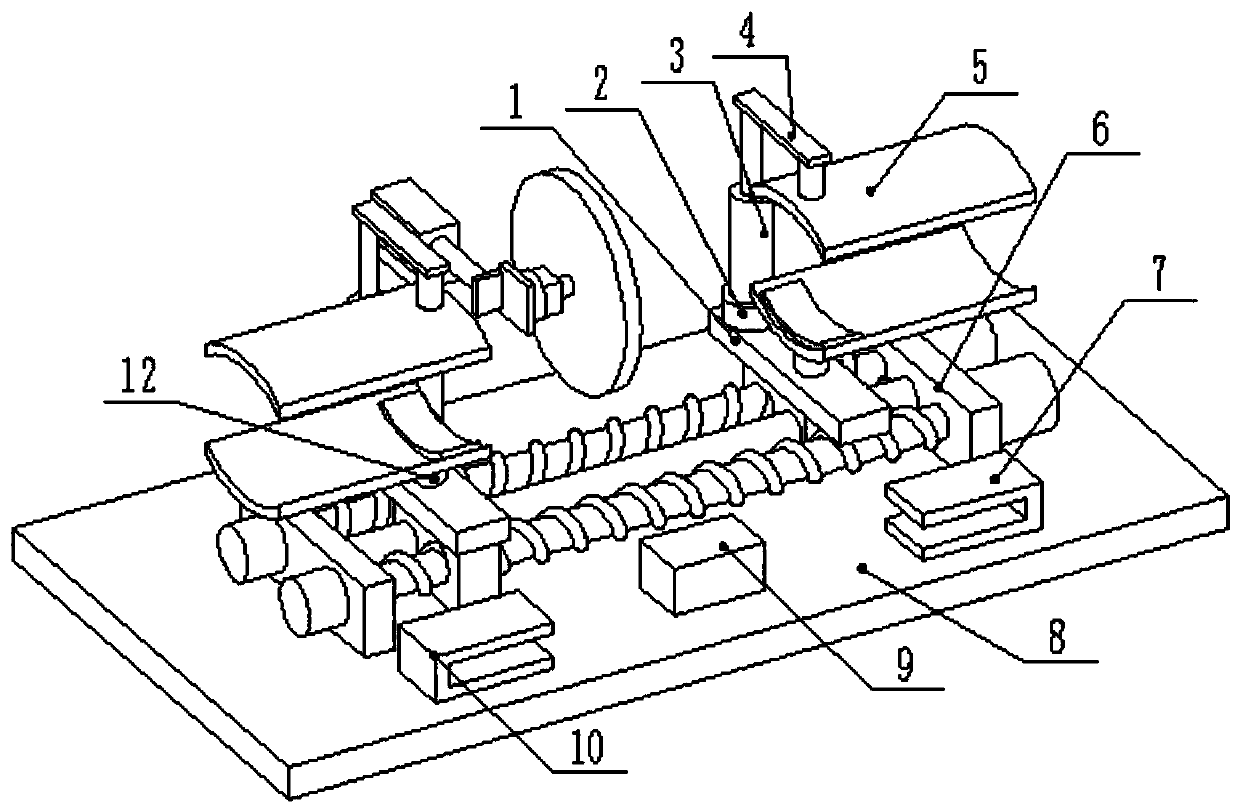

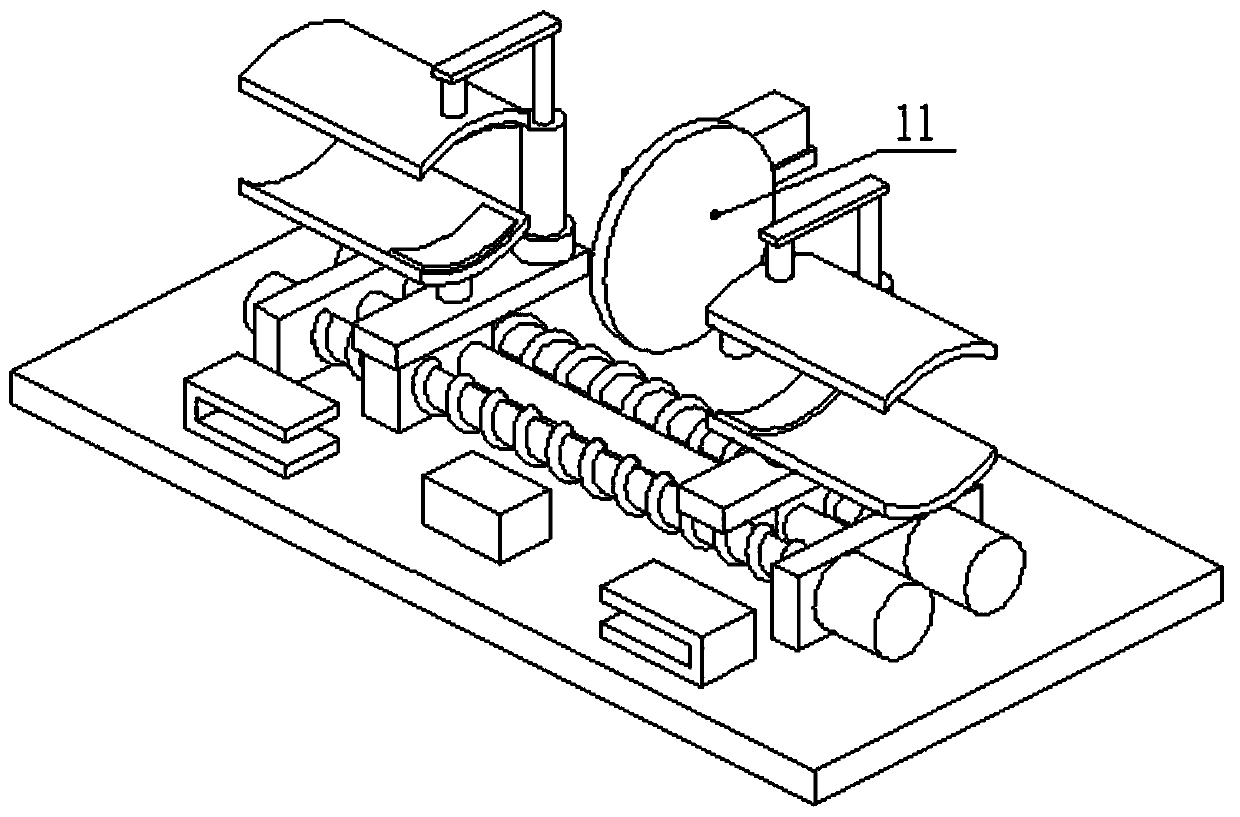

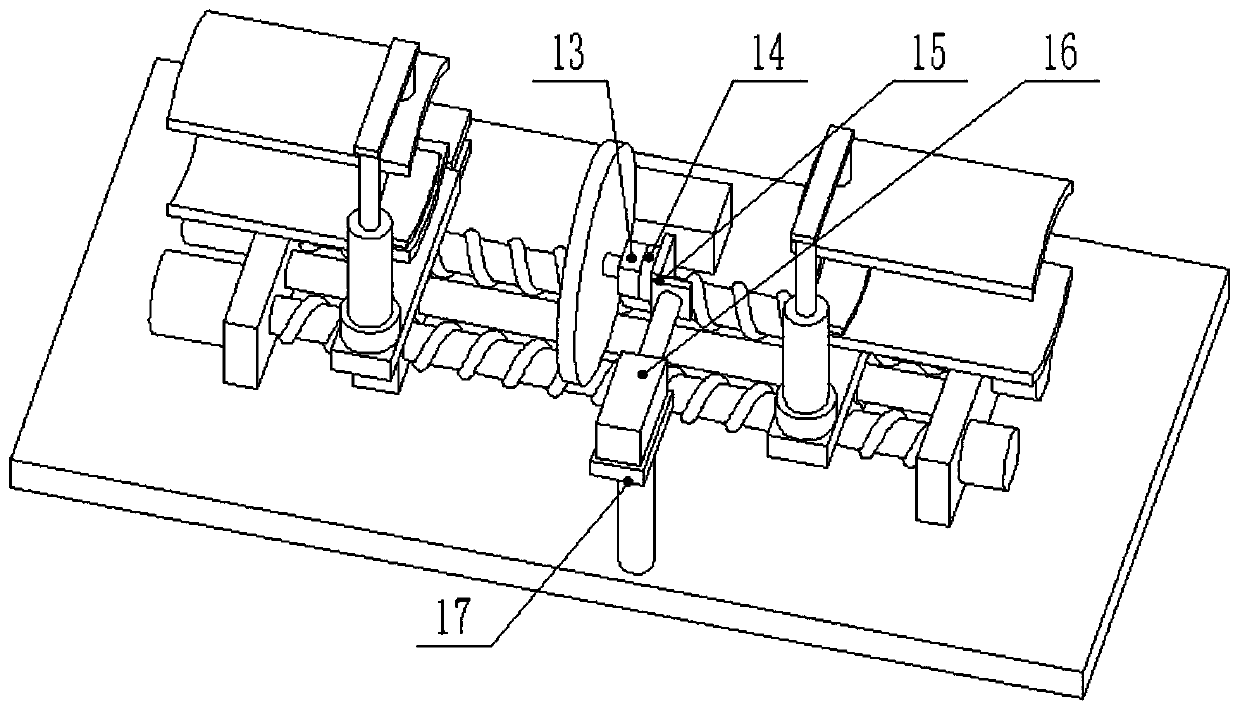

[0020] The present invention is achieved through the following technical solutions: an auxiliary welding device for steel pipes for construction, including a first support 1, a first pressure sensor 2, a first hydraulic cylinder 3, a second support 4, a pressing device 5, and a transmission device 6 , first switch 7, workbench 8, controller 9, second switch 10, grinding wheel 11, third support 12, first motor 13, second pressure sensor 14, fourth support 15, second hydraulic cylinder 16 and hydraulic pressure Cylinder base 17, the front position above the middle of the workbench 8 is fixedly connected to the controller 9, the top of the workbench 8 is fixedly connected to the transmission device 6, and the left side above the workbench 8 is fixed to the second switch 10 connection, the upper right side of the workbench 8 is fixedly connected with the first switch 7, the two sides above the transmission device 6 are fixedly connected with the first bracket 1, and the middle posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com