Feeding frame of printed circuit board

A printed circuit board and material rack technology, which is applied to tool storage devices, manufacturing tools, etc., can solve the problems of inability to apply printed circuit boards, poor versatility of feeding racks, and high input costs, saving loading time, ingenious structural design, The effect of high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with an SMT production line adopting the structure of the present invention.

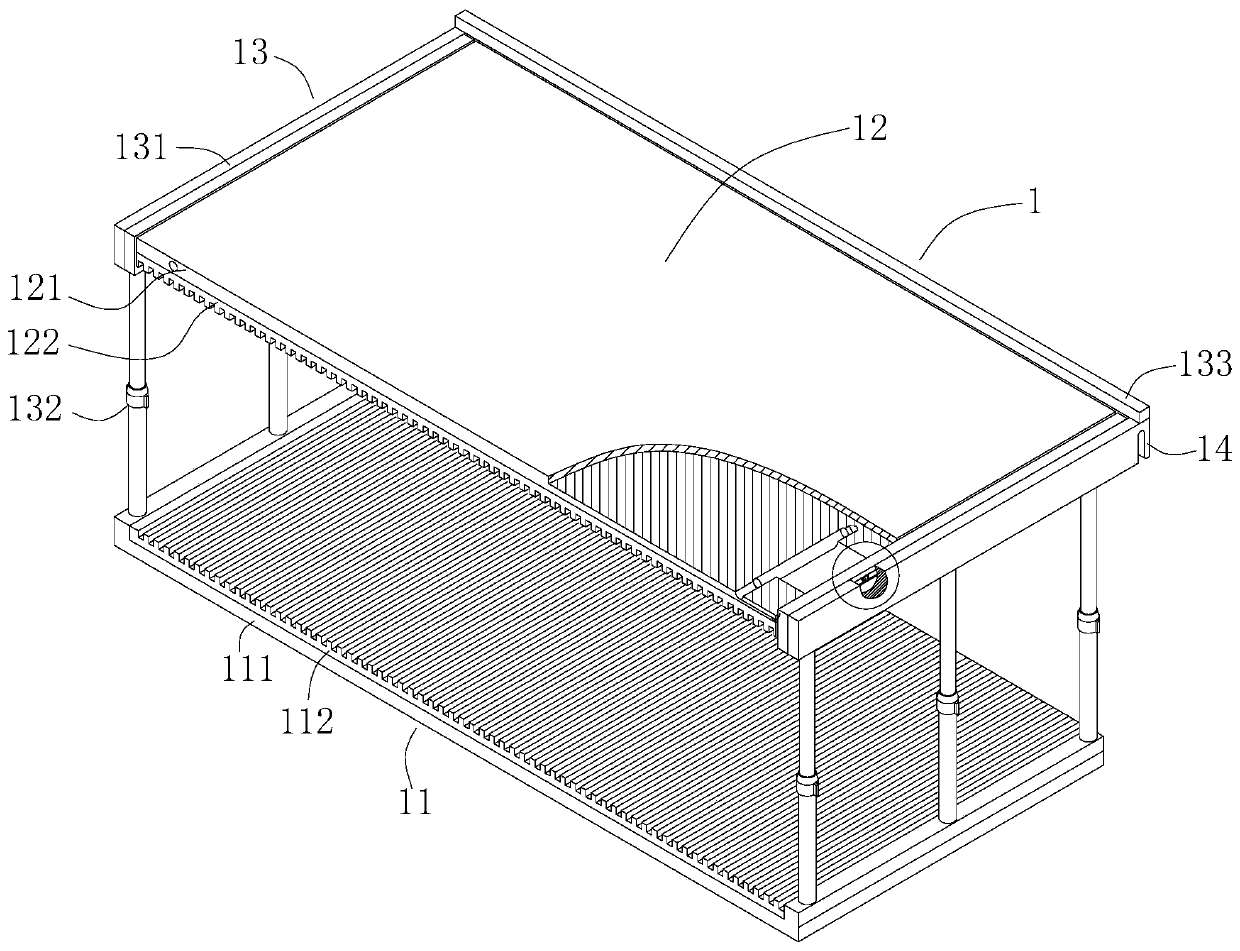

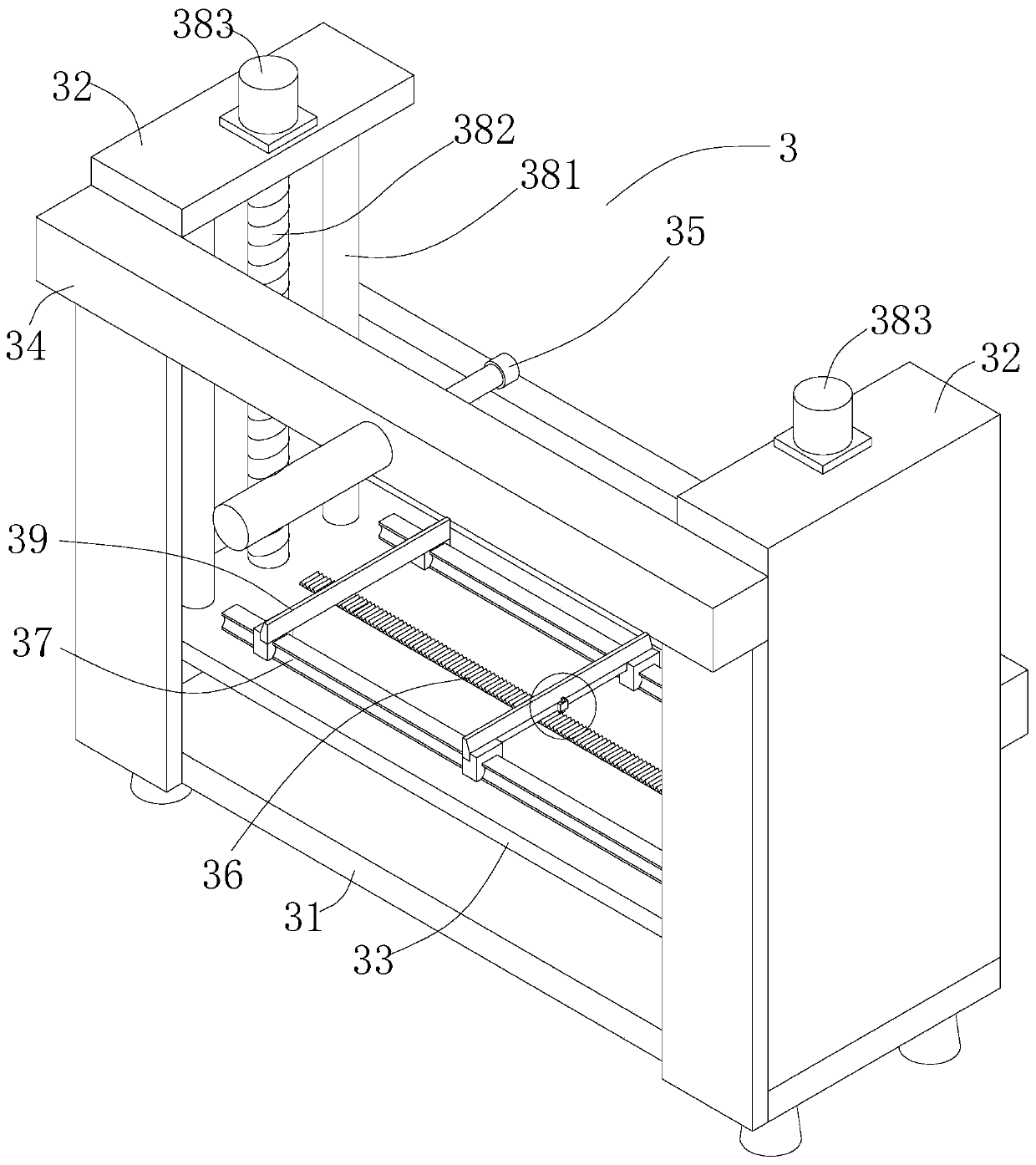

[0032] During the specific implementation: a kind of SMT production line, including a plurality of soldering lines composed of placement machines, reflow soldering and wave furnaces, and also includes an automatic conveying frame 3 for conveying printed circuit boards and a feeding material for placing printed circuit boards Rack 1, such as Figure 1 to Figure 4 shown.

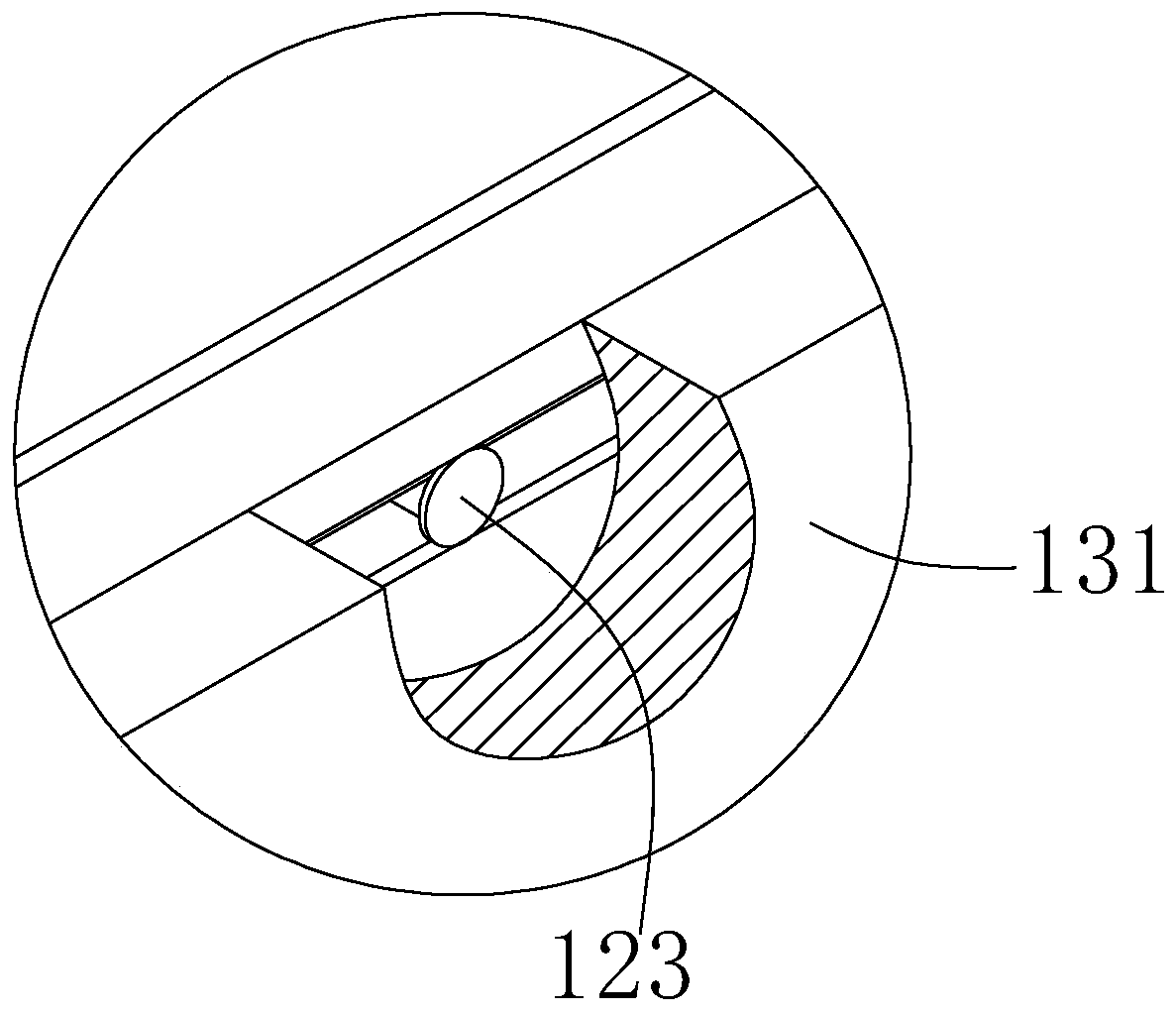

[0033] The loading rack 1 includes a main board assembly 11 and an auxiliary board assembly 12 that are erected and parallel to each other, and side frames 13 that are symmetrically arranged on both sides of the main board assembly 11 in the length direction. The cross beam 131 arranged parallel to the main board assembly 11, the cross beam 131 is installed on the main board assembly 11 through at least two vertical columns 132; the auxiliary boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com