Preparation method of mesoporous y molecular sieve

A molecular sieve and mesoporous technology, applied in the field of preparation of mesoporous Y molecular sieves, can solve the problems of low sample solid yield, poor internal mesopore order, and low crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

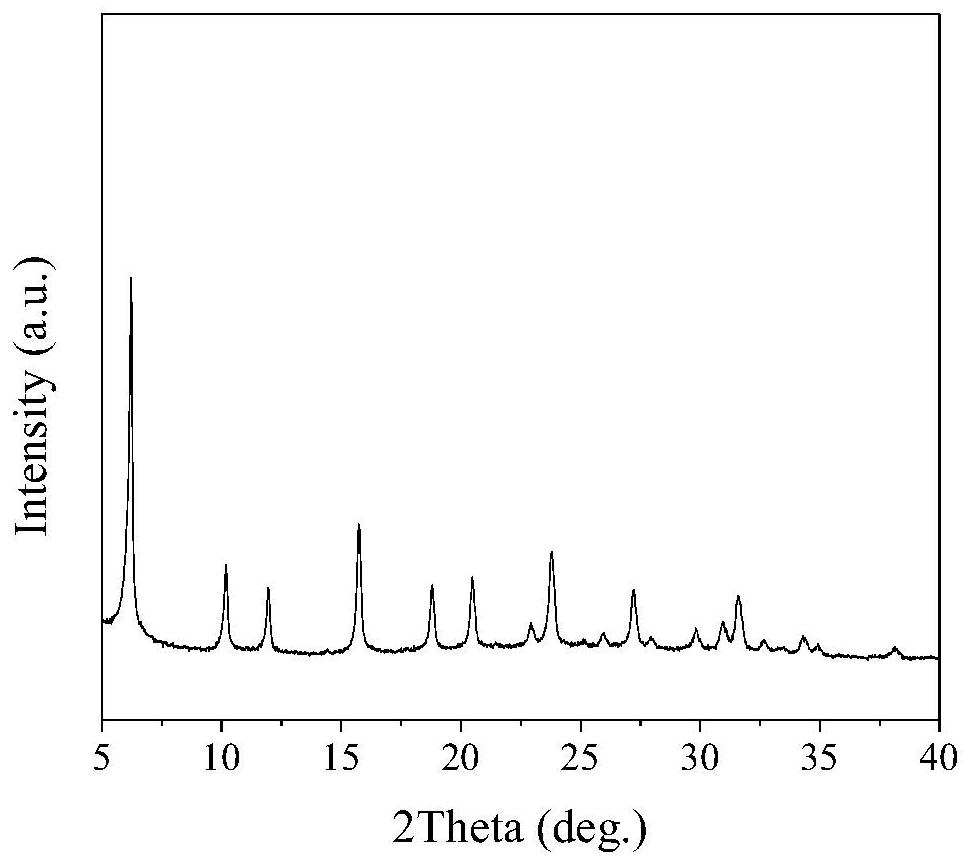

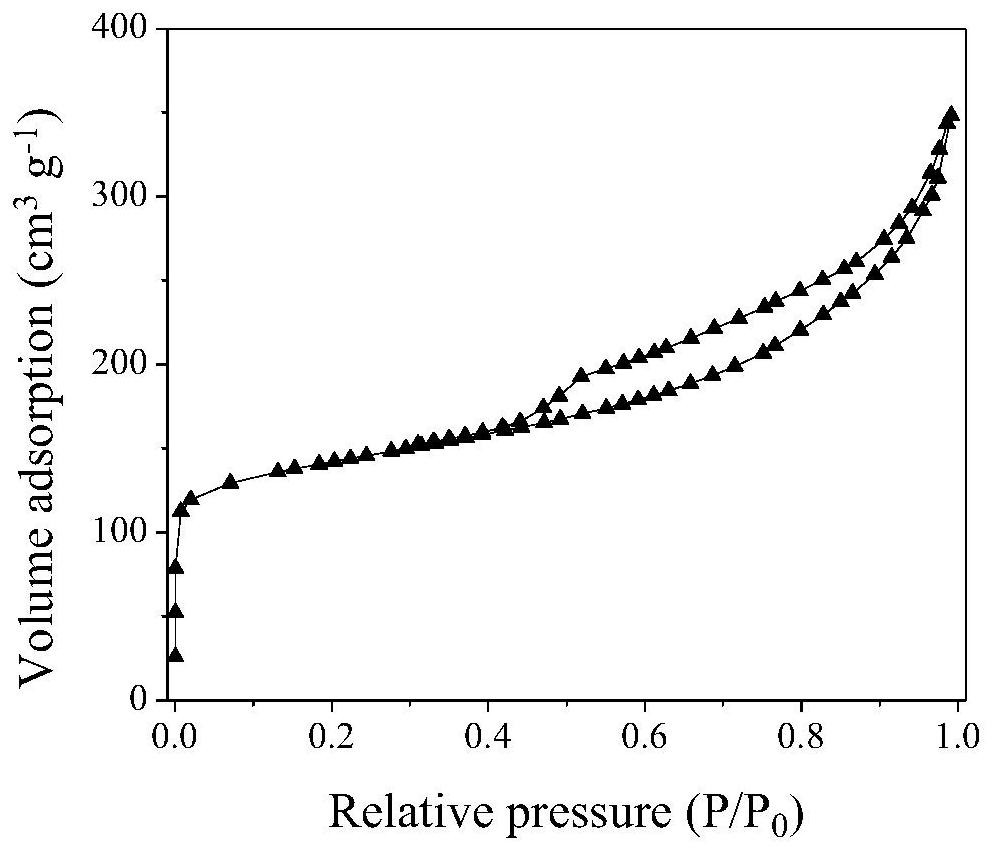

[0033] With 10 grams of Y molecular sieves and 0.472 grams of ordered mesoporous directing agent (wherein R 2 , R 3 , R 4 is hydrogen; R 1 and R 5 For methyl) mixed uniformly to obtain mixed solution A, after stirring at 30°C for 15 minutes, add 100 grams of 0.2M sodium hydroxide solution to mixed solution A to obtain mixed solution C, mixed solution C was centrifuged and washed at 25°C for 120 minutes, After drying, the mesoporous Y molecular sieve is obtained. Wherein, the molar ratio of the ordered mesoporous directing agent to the Y molecular sieve is 0.025:1, and the mass ratio of the sodium hydroxide solution to the Y molecular sieve is 10:1. The XRD spectrum pattern of gained mesoporous Y molecular sieve is as follows figure 1 As shown, there is a strong diffraction peak attributed to the MFI topology. Nitrogen adsorption and desorption isotherms figure 2 As shown, it is a mixed nitrogen adsorption curve of type I and type IV, and it is multi-layer adsorption in...

Embodiment 2

[0035] 10 grams of Y molecular sieve and 4.24 grams of ordered mesoporous directing agent (wherein R 1 , R 3 , R 5 is hydrogen; R 2 is ethyl, R 4 For methyl) mixed uniformly to obtain mixed solution A, after stirring at 80°C for 95 minutes, add 400 grams of 0.5M sodium hydroxide solution to mixed solution A to obtain mixed solution C, mixed solution C was centrifuged and washed at 25°C for 15 minutes, After drying, the mesoporous Y molecular sieve is obtained. Wherein, the molar ratio of the ordered mesoporous directing agent to the Y molecular sieve is 0.2:1, and the mass ratio of the sodium hydroxide solution to the Y molecular sieve is 40:1. The XRD spectrum pattern of gained mesoporous Y molecular sieve is as follows figure 1 As shown, there is a strong diffraction peak attributed to the MFI topology. Nitrogen adsorption and desorption isotherms figure 2 As shown, it is a mixed nitrogen adsorption curve of type I and type IV, and it is multi-layer adsorption in the...

Embodiment 3

[0037] 10 grams of Y molecular sieve and 1.177 grams of ordered mesoporous directing agent (wherein R 1 , R 3 , R 5 is hydrogen; R 2 is ethyl, R 4 Ethyl) was mixed uniformly to obtain a mixed solution A, after stirring at 50°C for 65 minutes, 300 grams of 0.3M sodium hydroxide solution was added to the mixed solution A to obtain a mixed solution C, and the mixed solution C was stirred at 60°C for 40 minutes and then centrifuged and washed. After drying, the mesoporous Y molecular sieve is obtained. Wherein, the molar ratio of the ordered mesoporous directing agent to the Y molecular sieve is 0.05:1, and the mass ratio of the sodium hydroxide solution to the Y molecular sieve is 30:1. The XRD spectrum pattern of gained mesoporous Y molecular sieve is as follows figure 1 As shown, there is a strong diffraction peak attributed to the MFI topology. Nitrogen adsorption and desorption isotherms figure 2 As shown, it is a mixed nitrogen adsorption curve of type I and type IV,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com