Method for separating silver and copper in silver electrolysis waste liquid

A technology for electrolytic waste liquid and silver-copper, applied in chemical instruments and methods, copper sulfate, silver compounds, etc., can solve the problems of frequent liquid production, low reactivity of silver oxide powder, and high silver content, so as to reduce the frequency of liquid production and The amount of liquid production, the reduction of yellow smoke, and the excellent recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

[0027] 1. Preparation and detection of silver nitrate crystals and concentrated mother liquor:

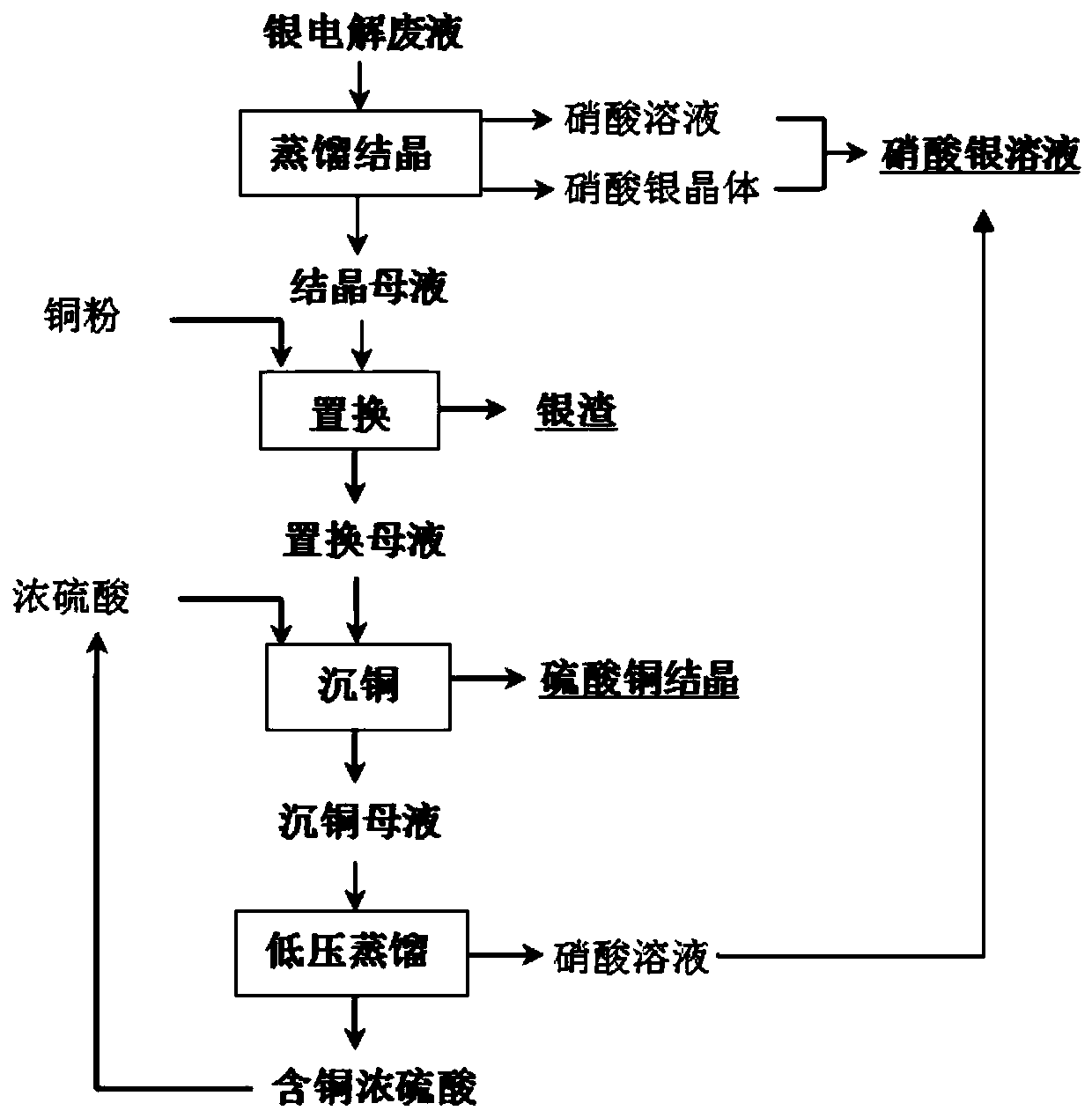

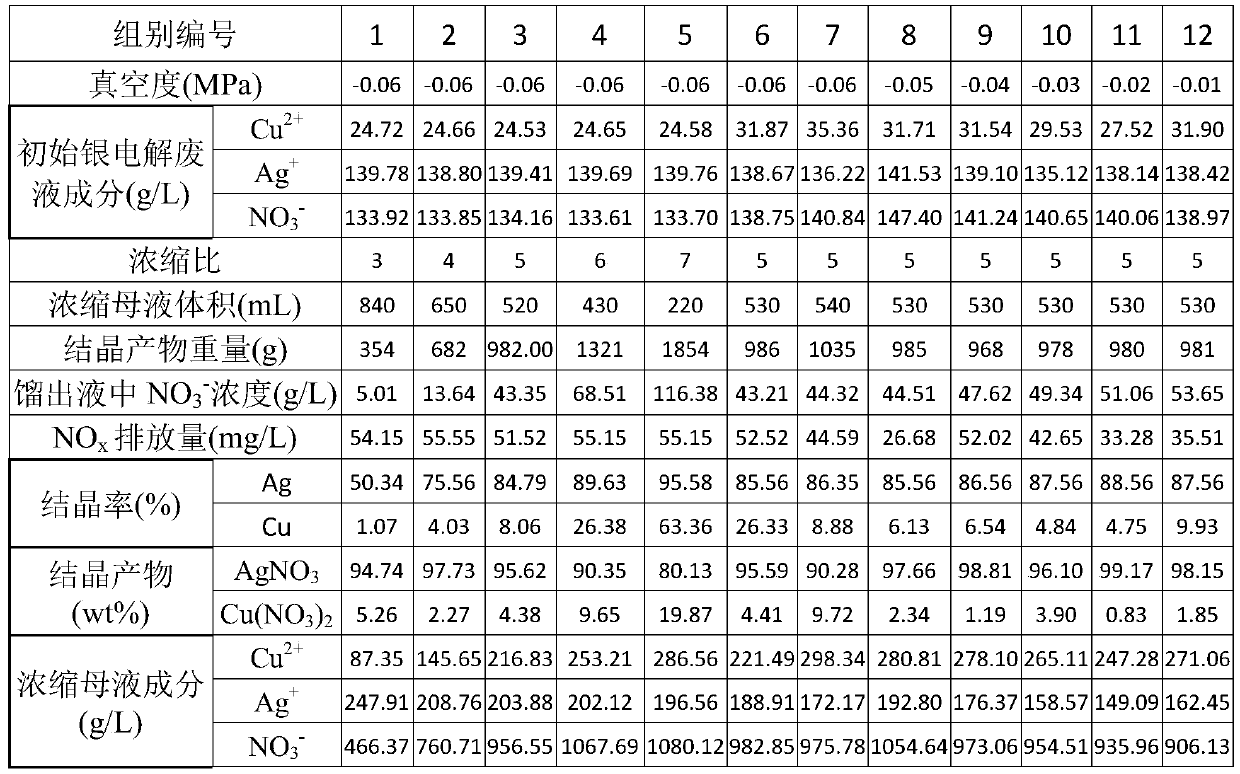

[0028] The silver electrolysis waste liquid is placed in a closed heating container for vacuum distillation and concentration, then heating is stopped (75-80° C.), after natural cooling, silver nitrate crystals and concentrated mother liquor are obtained, and the distillation product is collected and condensed to obtain a distillate, The specific preparation parameters and detection parameters are shown in Table 1.

[0029] Table 1 vacuum distillation, filtration step specific process parameters and detection results.

[0030]

[0031] As can be clearly seen from the above table, in the process of preparing silver nitrate crystals and concentrated mother liquor, the optimal volume ratio of silver electrolytic waste liquid and obtained concentrated mother liquor after vacuum distillation is 5:1 (i.e., the concentration ratio is 5 times).

[0032] 2. Preparati...

Example Embodiment

[0043] Example 2

[0044] Adopt the same method as Example 1 to separate silver and copper in the silver electrolysis waste liquid, wherein, the relative vacuum degree is controlled at -0.06MPa, the concentration ratio of vacuum distillation is 5 times, and after heating is stopped, it is cooled to room temperature and filtered to obtain a crystalline product And concentrated mother liquor mother liquor, then replace according to the content of 0.7g copper powder added per liter of concentrated mother liquor, filter to obtain silver slag and replacement mother liquor after reaction for 30min, then add concentrated sulfuric acid in the amount of 700mL of concentrated sulfuric acid added to each liter of replacement mother liquor, After stirring and cooling to room temperature, filter to obtain copper sulfate filter residue and copper precipitation waste liquid. Repeated the test for many times, the test results showed that the silver ion concentration in the replacement mother ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com