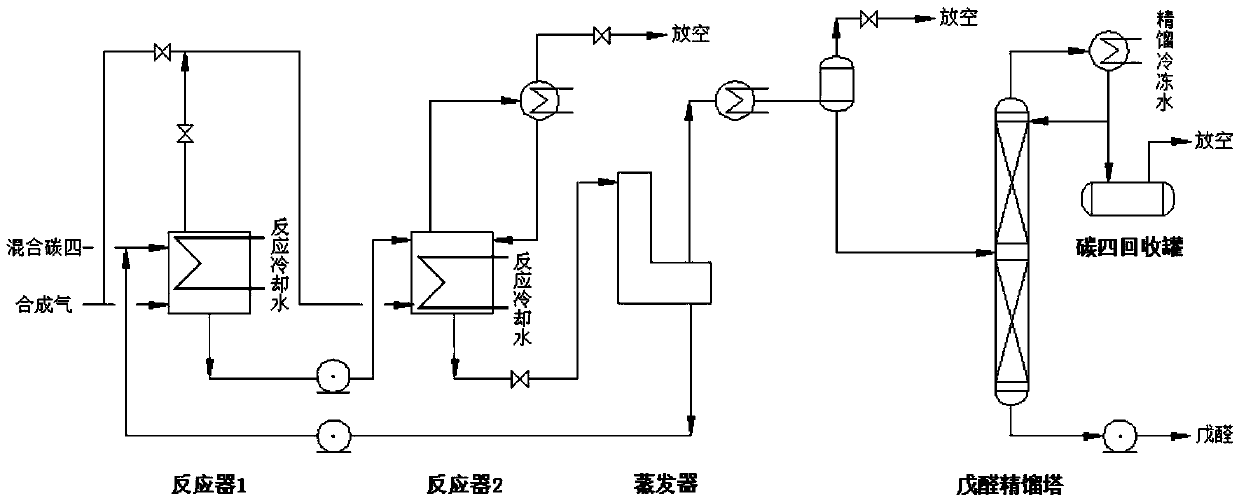

Refrigeration cycle system and method used in process of preparing C5 aldehyde through hydroformylation of mixed C4 olefins

A carbon tetraolefin hydroformyl and circulation system technology, which is applied in the production of carbon monoxide reaction, separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of high energy consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

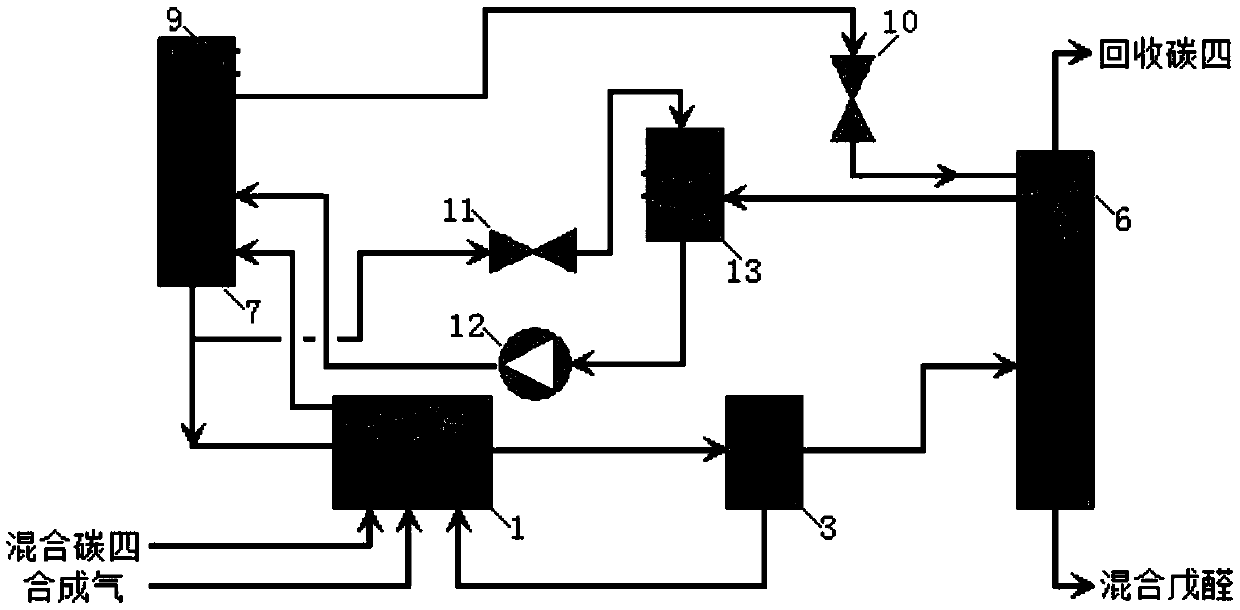

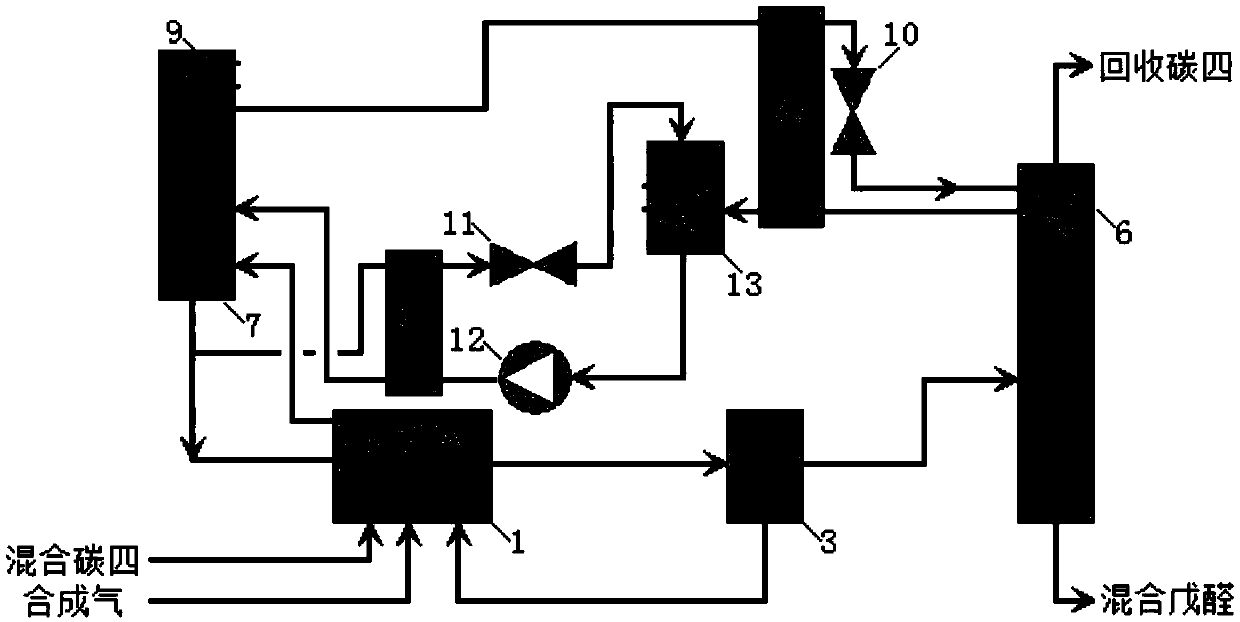

[0086] In this embodiment, use such as Figure 5 In the shown refrigeration cycle system, the flow rate of the ammonia-water working fluid infusion pump of the refrigerator is 13.9kg / hr (ammonia mass content 0.50) for the first-stage absorption refrigeration subsystem and 10.0kg / hr (ammonia) for the second-stage absorption refrigeration system. The mass content is 0.375). In the first-stage absorption refrigeration subsystem method, the high temperature level is 86.1℃ (the first-stage heat exchanger 2 ammonia side of the hydroformylation reactor), and the intermediate temperature is 40.0℃ (the first-stage absorber 20 and the first The high-pressure section pressure is 15.3 bar, and the low-pressure section pressure is 6.1 bar. In the second-stage absorption refrigeration system method, the high temperature is 86.3℃ (the second-stage heat exchanger 15 ammonia side of the hydroformylation reactor), and the middle temperature is 19.9℃ (the second-stage distillation condenser 9 se...

Embodiment 2

[0089] In this embodiment, use such as Figure 5 In the refrigeration cycle system shown, the flow rate of the refrigerating machine ammonia-water working medium infusion pump is 13.9kg / hr (ammonia mass content 0.45) for the first-stage absorption refrigeration subsystem and 10.0kg / hr (ammonia) for the second-stage absorption refrigeration system. The mass content is 0.312). In the first-stage absorption refrigeration subsystem method, the high temperature is 96.2℃ (the first-stage heat exchanger 2 ammonia side of the hydroformylation reactor), and the intermediate temperature is 40.0℃ (the first-stage absorber 20 and the first The high-pressure section pressure is 15.3 bar, and the low-pressure section pressure is 5.0 bar. In the second-stage absorption refrigeration system method, the high temperature is 96.1℃ (the second-stage heat exchanger 15 ammonia side of the hydroformylation reactor), and the middle temperature is 15.0℃ (the second-stage distillation condenser 9 secon...

Embodiment 3

[0092] In this embodiment, use such as Figure 5 As shown in the refrigeration cycle system, the flow rate of the refrigerating machine ammonia-water working medium infusion pump is 13.9kg / hr (ammonia mass content 0.56) for the first-stage absorption refrigeration subsystem and 10.0kg / hr (ammonia The mass content is 0.45). In the first-stage absorption refrigeration subsystem method, the high temperature level is 76.0℃ (the first-stage heat exchanger 2 ammonia side of the hydroformylation reactor), and the intermediate temperature is 40.0℃ (the first-stage absorber 20 and the first The high-pressure section pressure is 15.3bar and the low-pressure section pressure is 7.2bar. In the second-stage absorption refrigeration system method, the high temperature level is 76.6°C (the second-stage heat exchanger 15 ammonia side of the hydroformylation reactor), and the middle temperature is 25.2°C (the second-stage distillation condenser 9 second-stage Side) and 40.0°C (the second-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com