Lithium-based lubricating grease composition and preparation method thereof

A lithium-based grease and composition technology, applied in the field of grease, can solve the problems of dark color, opaque appearance, rare grease appearance, color and low noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

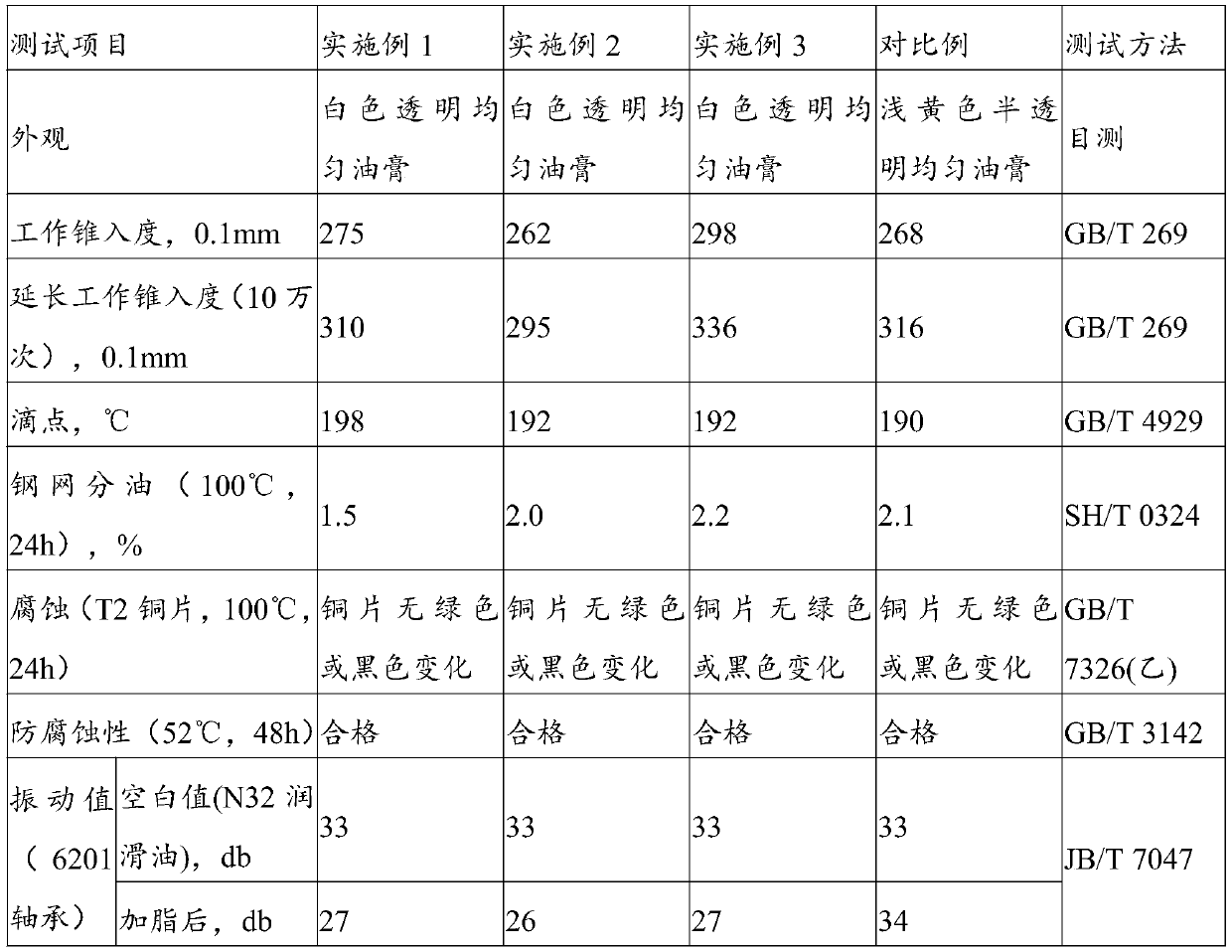

Examples

Embodiment 1

[0030] A white transparent low-noise lithium-based grease composition, consisting of the following components in parts by weight: N4006 rubber filler oil produced by Karamay Petrochemical Company (40°C kinematic viscosity 54mm 2 / s) 87kg, lauryl hydroxystearic acid 6kg, stearic acid 4.5kg, naphthenic acid 0.3kg, alkyl salicylic acid 0.2kg, lithium hydroxide 1.7kg and N-phenyl-ɑ-naphthylamine 0.3kg .

[0031] The preparation method comprises the following steps:

[0032] (1) Stir 40kg of N4006 rubber filler oil and raise the temperature to 60°C;

[0033] (2) Then add lauryl hydroxystearic acid, stearic acid, naphthenic acid, and alkyl salicylic acid, mix well, stir for 15 minutes, and then carry out saponification reaction with lithium hydroxide aqueous solution at a temperature of 85°C and keep for 90 minutes;

[0034] (3) Heat up to 120°C for dehydration and keep for 60 minutes; further heat up to 205°C and keep for 5 minutes;

[0035] (4) Add the remaining N4006 rubber fi...

Embodiment 2

[0040] A white transparent low-noise lithium-based grease composition, consisting of the following components in parts by weight: N4010 rubber filler oil produced by Liaoning Haihua Petrochemical Company (40°C kinematic viscosity 167mm 2 / s) 85kg, lauryl hydroxystearic acid 7kg, stearic acid 5kg, naphthenic acid 0.3kg, alkyl salicylic acid 0.4kg, lithium hydroxide 2kg and diisooctyl diphenylamine 0.3kg.

[0041] The preparation method comprises the following steps:

[0042] (1) Stir 42kg of N4010 rubber filling oil and raise the temperature to 65°C;

[0043] (2) Then add lauryl hydroxystearic acid, stearic acid, naphthenic acid, and alkyl salicylic acid, mix well, stir for 15 minutes, and then carry out saponification reaction with lithium hydroxide aqueous solution at a temperature of 85°C and keep for 80 minutes;

[0044] (3) Heating and dehydration, 125°C, keep for 60min; further heat up to 200°C, keep for 10min;

[0045] (4) Add remaining N4010 rubber filling oil to the ...

Embodiment 3

[0050] A white transparent low-noise lithium-based grease composition, consisting of the following components in parts by weight: N4016 rubber filler oil produced by Panjin North Asphalt Company (40°C kinematic viscosity 322mm 2 / s) 89.6kg, lauryl hydroxystearic acid 5kg, stearic acid 3.2kg, naphthenic acid 0.3kg, alkyl salicylic acid 0.3kg, lithium hydroxide 1.4kg and diphenylamine 0.2kg.

[0051] The preparation method comprises the following steps:

[0052] (1) Stir 44kg of N4016 rubber filling oil and heat up to 70°C;

[0053] (2) Then add lauryl hydroxystearic acid, stearic acid, naphthenic acid, and alkyl salicylic acid, mix well, stir for 15 minutes, and then carry out saponification reaction with lithium hydroxide aqueous solution at a temperature of 95°C and keep for 90 minutes;

[0054] (3) Heating and dehydration, 130°C, keep for 60min; further heat up to 200°C, keep for 5min;

[0055] (4) Add remaining N4016 rubber filling oil to the reaction system, circulate, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com