A vertical electroplating equipment

An electroplating equipment and vertical technology, applied in the field of vertical electroplating equipment, can solve the problems of increasing processing time, reducing processing efficiency, affecting electroplating efficiency and coating quality, etc., and achieving the effect of preventing clogging and improving electroplating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

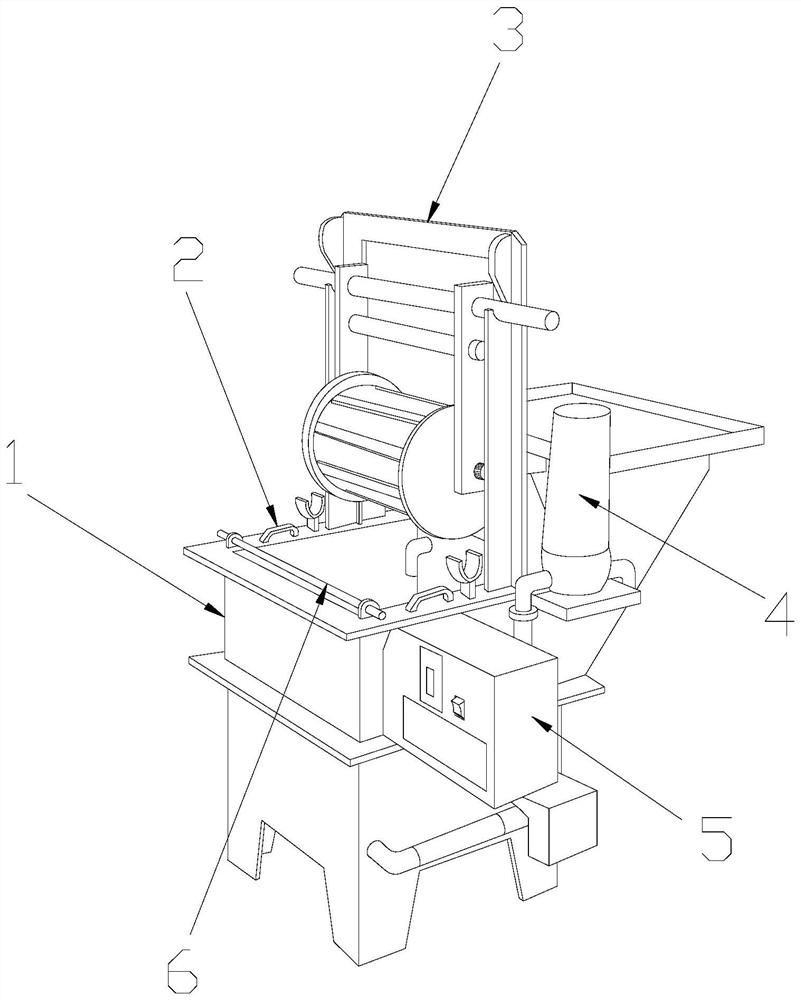

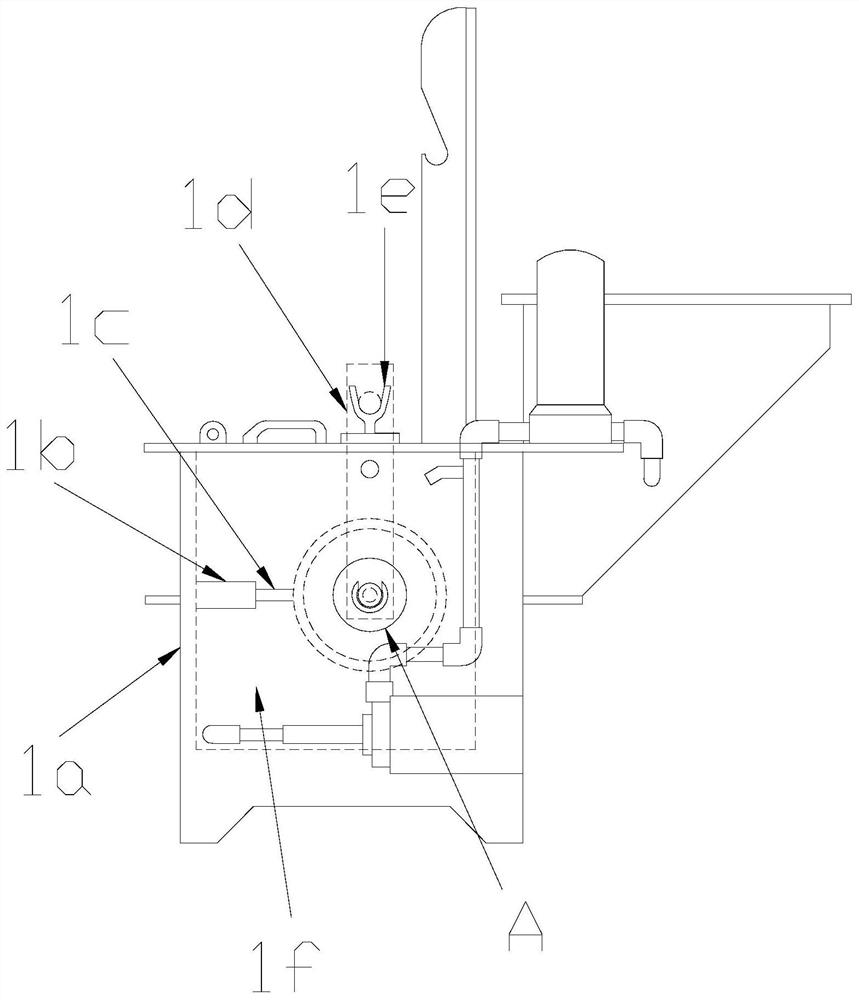

[0025] see Figure 1-Figure 4 , the present invention provides a kind of upright electroplating equipment, its structure comprises electroplating machine 1, lifting handle 2, drum filter support 3, filter 4, electric control box 5, anode rod 6, on the top of described electroplating machine 1 A drum filter support 3 is provided, and the electroplating machine 1 is glued to the drum filter support 3. An anode rod 6 is arranged on the top surface of the electroplater 1, and the electroplater 1 and the anode rod 6 connected, a handle 2 is provided between the anode rod 6 and the drum filter support 3, the handle 2 is fixedly connected with the electroplating machine 1, and the surface of the electroplating machine 1 is provided with a filter 4 , the electroplating machine 1 is connected with the filter 4, the electric control box 5 is installed on the surface of the electroplating machine 1, and the electroplating machine 1 is composed of an upright chassis 1a, a movable mounting...

Embodiment 2

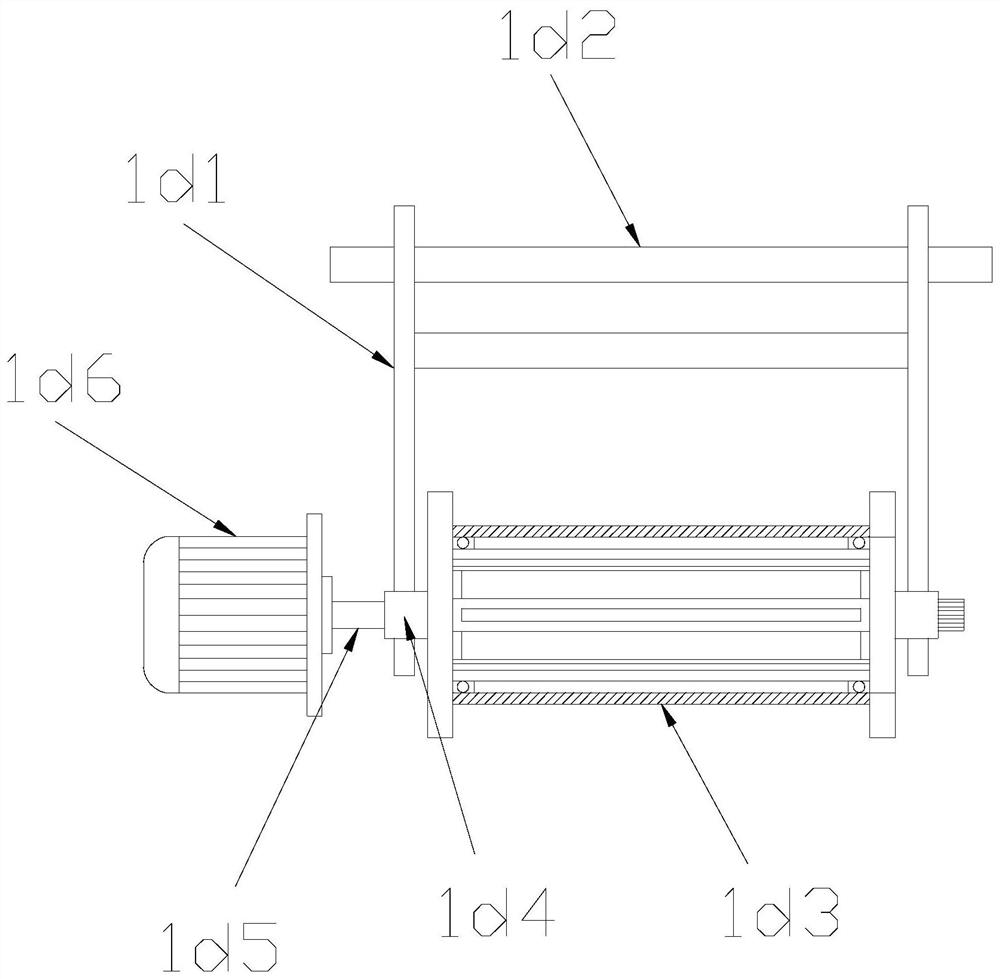

[0031] see Figure 1-Figure 6 , the present invention provides a kind of upright electroplating equipment, described sweeping mechanism 1d36 is made up of rotating shaft g1, gear g2, sweeping brush g3, fixed shaft g4, described rotating shaft g1 is provided with gear g2 on the right end, described The rotating shaft g1 and the gear g2 are fixedly connected, the left end of the rotating shaft g1 is provided with a fixed shaft g4, the rotating shaft g1 and the fixed shaft g4 are an integrated structure, and the rotating shaft g1 is equidistantly distributed on the surface There are four leveling brushes g3, and the rotating shaft g1 is connected with the leveling brushes g3.

[0032] The surface of the gear g2 is provided with a positioning U-shaped bar g21, and the gear g2 is movably connected with the positioning U-shaped bar g21.

[0033] The cleaning brush 1c is connected with the filter inner barrel 1d33 through the filter screen 1d34, and is used to clean the filter scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com