Device and method for pressure control, enabling maintenance of unit positive pressure, and air conditioning device

A pressure control and unit technology, applied in mechanical equipment, lighting and heating equipment, refrigerators, etc., can solve problems such as easy air infiltration and refrigerant mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

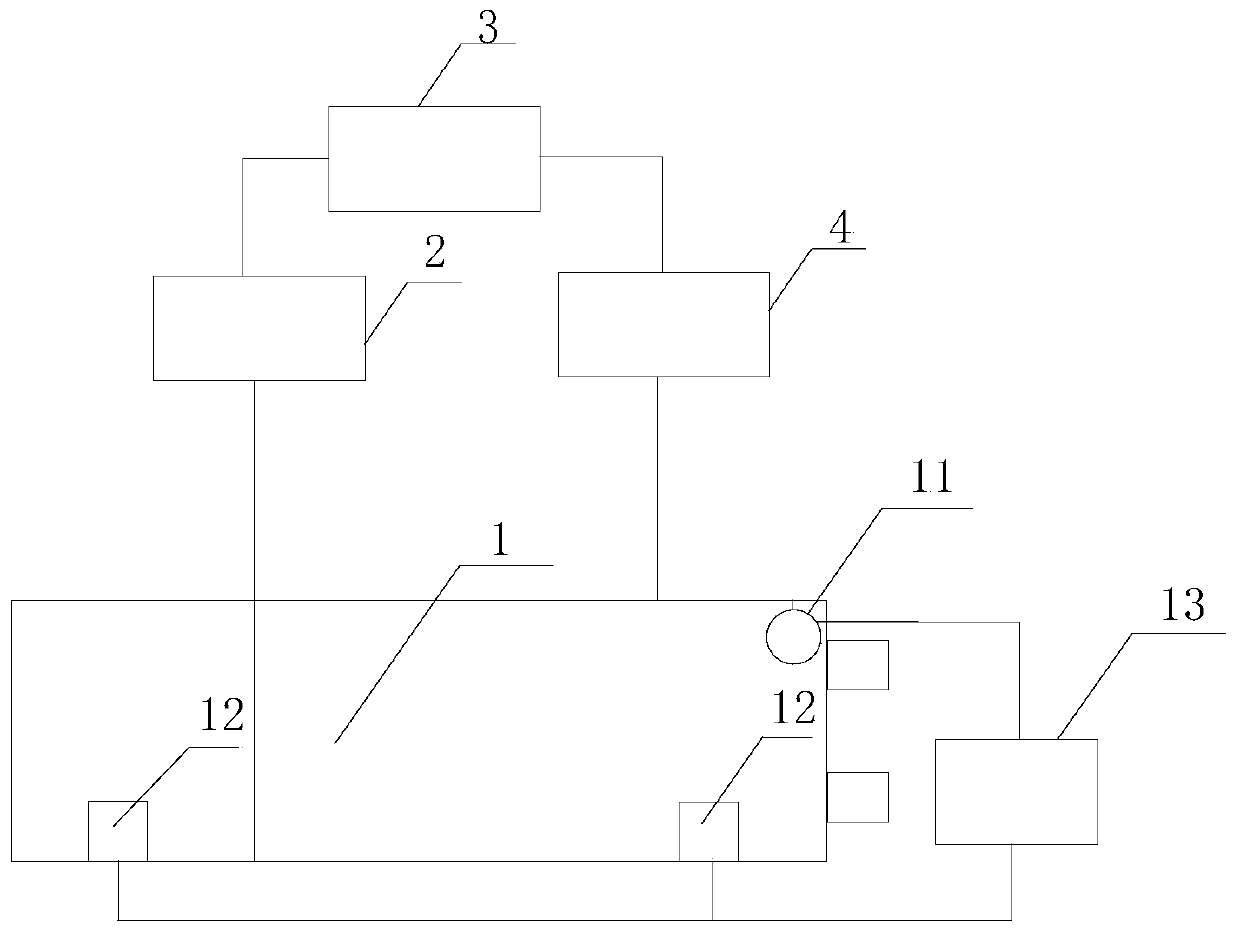

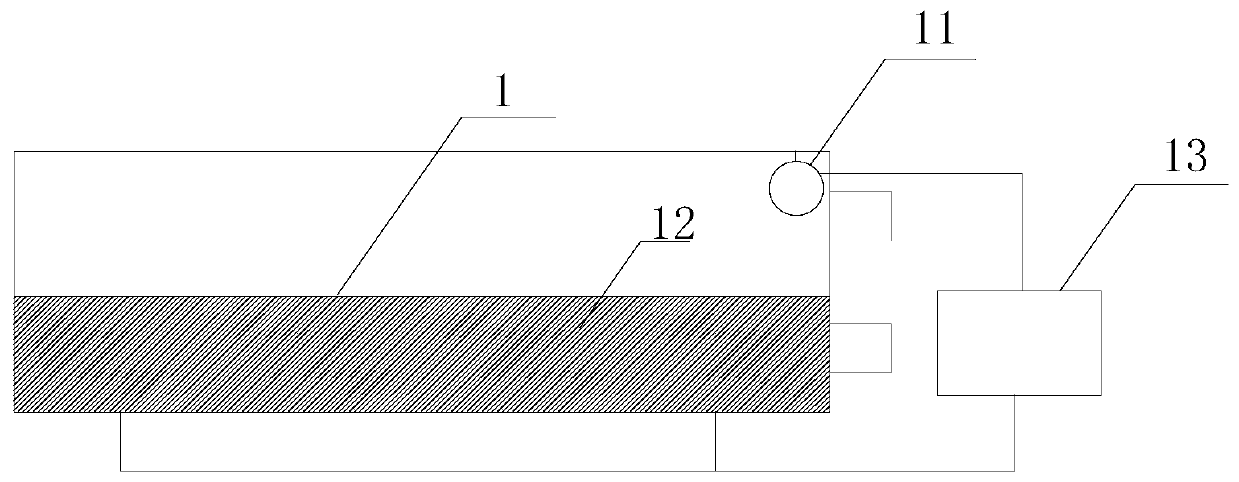

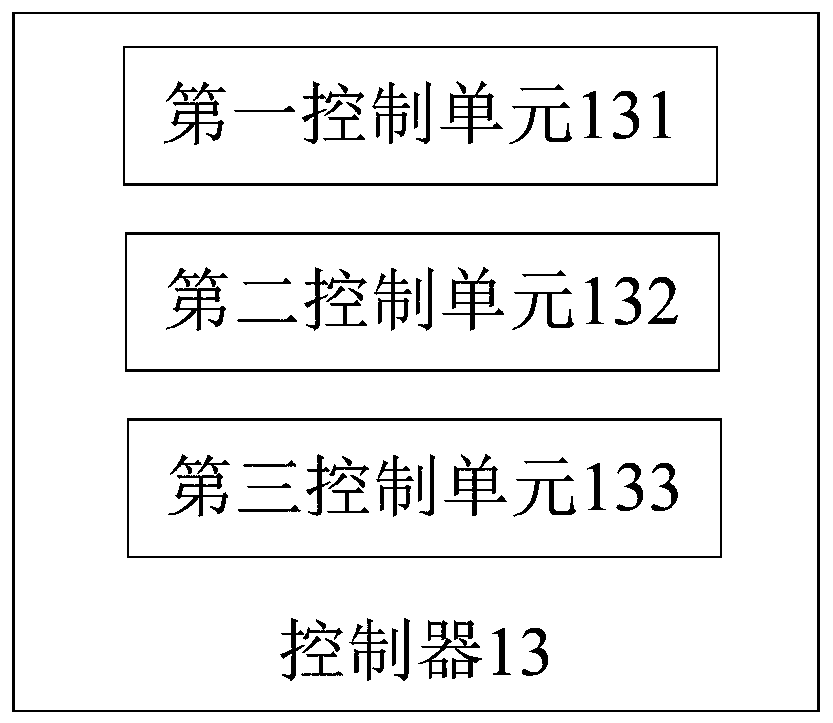

[0055] This embodiment provides a pressure control device for maintaining the positive pressure of the unit, figure 1 is a structural diagram of a pressure control device according to an embodiment of the present invention, such as figure 1As shown, the device includes: a pressure sensor 11 arranged inside the condenser 1 for detecting the internal pressure of the condenser; a heater 12 used for heating the refrigerant inside the condenser 1 to improve the condenser Internal pressure; controller 13, one end is connected to the pressure sensor 11, and the other end is connected to the heater 12, which is used to control the opening or closing of the heater 12 according to the internal pressure of the condenser when the unit is shut down .

[0056] In a specific implementation, the number of the heater 12 may be one, two, or multiple. In this embodiment, in order to achieve uniform heating of the condenser 1 . There are two heaters 12, and those skilled in the art can set diff...

Embodiment 2

[0066] Another optional embodiment of the present invention will be described in detail below by taking a water chiller as an example. This embodiment provides a pressure control device, Image 6 is a structural diagram of a pressure control device according to yet another embodiment of the present invention, such as Image 6 As shown, the device includes: a pressure sensor 611, an electric heater 612, and a controller (not shown in the figure).

[0067] In this embodiment, the pressure sensor 611 is arranged at the top of the inner space of the condenser 61. The top of the condenser 61 of the chiller is a gas refrigerant, and the bottom is a liquid refrigerant. The internal pressure of the entire condenser 61 is balanced, so the pressure sensor 611 It is arranged on the top of the condenser 61, and is used to detect the internal gas pressure of the condenser 61, that is, the condensation pressure;

[0068] In this embodiment, the electric heater 612 is arranged inside the co...

Embodiment 3

[0073] This embodiment provides a pressure control method, which is applied to the pressure control device in Embodiment 2, Figure 7 It is a flowchart of a pressure control method according to an embodiment of the present invention, such as Figure 7 As shown, the method includes:

[0074] S1, judging the operating state of the chiller, specifically, realizing the judgment of the operating state of the cold random group through the main controller, and the operating state includes the shutdown state and the startup state;

[0075] S2, when it is detected that the chiller is turned on, the electric heater is controlled to keep off to avoid waste of heat, and at the same time, the refrigerant purification device can also be controlled to purify the system refrigerant.

[0076] S3, when it is detected that the unit is in the shutdown state, judge the relationship between the condensing pressure Pc and the first preset value, wherein the first preset value is set according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com