Heating equipment capable of work and energy recycling

A technology of hot water equipment and equipment, applied in the field of functional reuse heating equipment, can solve problems such as high energy consumption and unaffordable costs for families

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

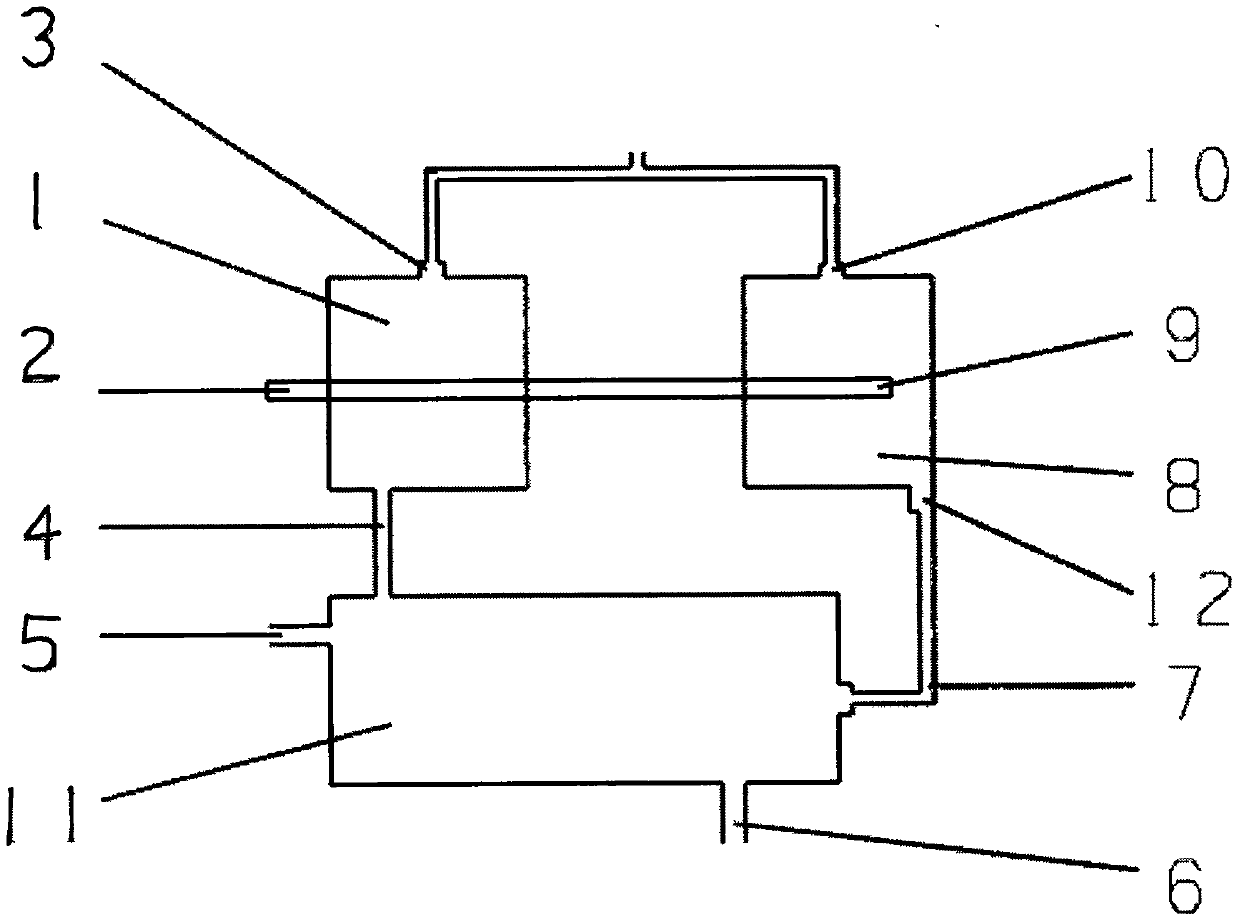

[0011] The invention provides a function reuse heating equipment, such as figure 1 As shown, the power input shaft of the 2-air compressor is driven by the external power source to make the 1-air compressor work, and the air is sucked in from the inlet of the 3-compressor, compressed into high-temperature and high-pressure gas, and discharged from the 4-compressor outlet, through the pipeline Enter the 11 air-water heat exchange device to transfer the heat energy in the high-temperature gas to the water, and the water temperature rises. There are 6 water inlets and 5 water outlets on the heat exchange device. The water inlet is connected to the water outlet of the external hot water equipment, and the water outlet Connect to the water inlet of the external hot water equipment.

[0012] After heat dissipation, the high-pressure gas passes through 7 pipes and connects to the air inlet of 12 air motors. The gas enters 8 air motors to make the air motors do work. The power output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com