Online sampling and waste material recycling device

A technology for recycling devices and samples, applied in the direction of sampling devices, transportation and packaging, conveyor objects, etc., can solve problems affecting the normal operation of equipment, achieve the effects of reducing labor intensity, avoiding environmental friendliness, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

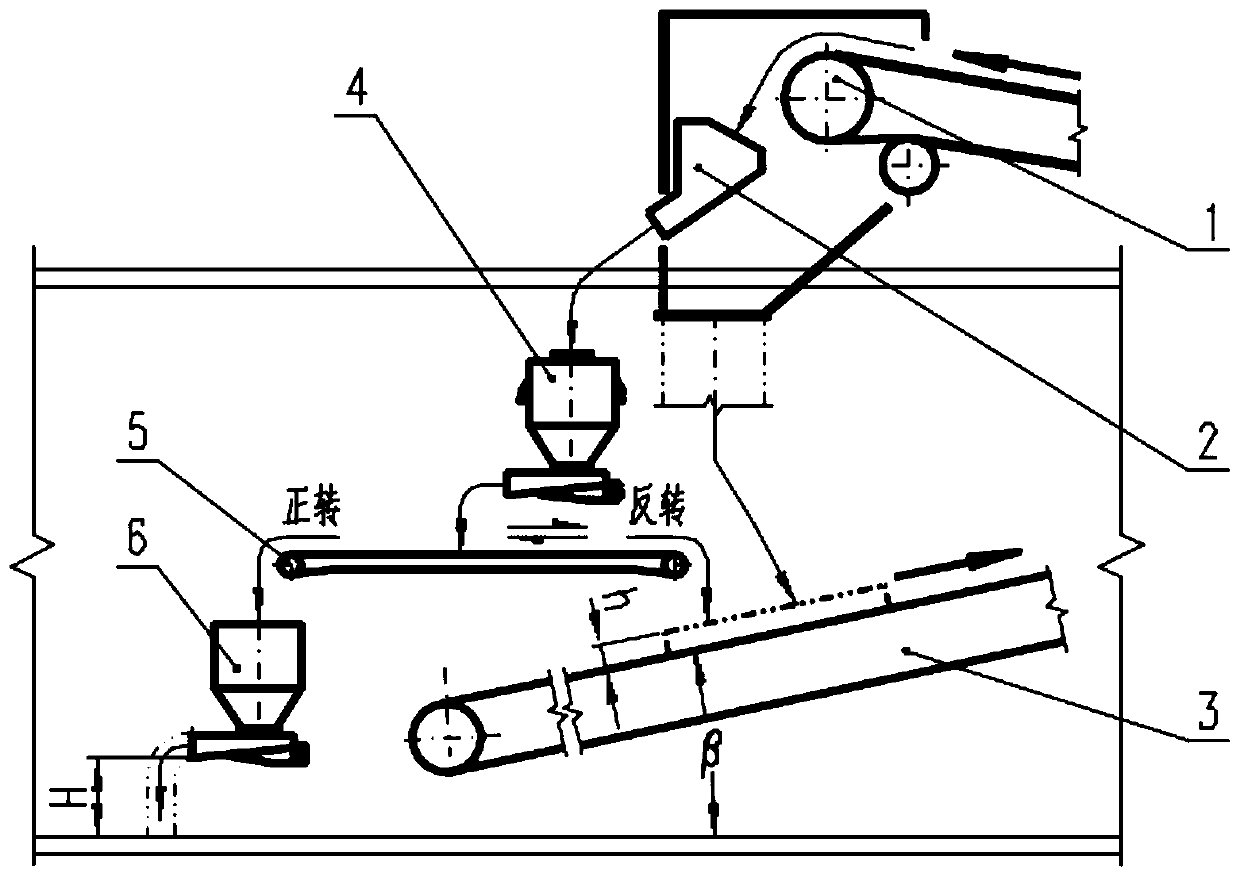

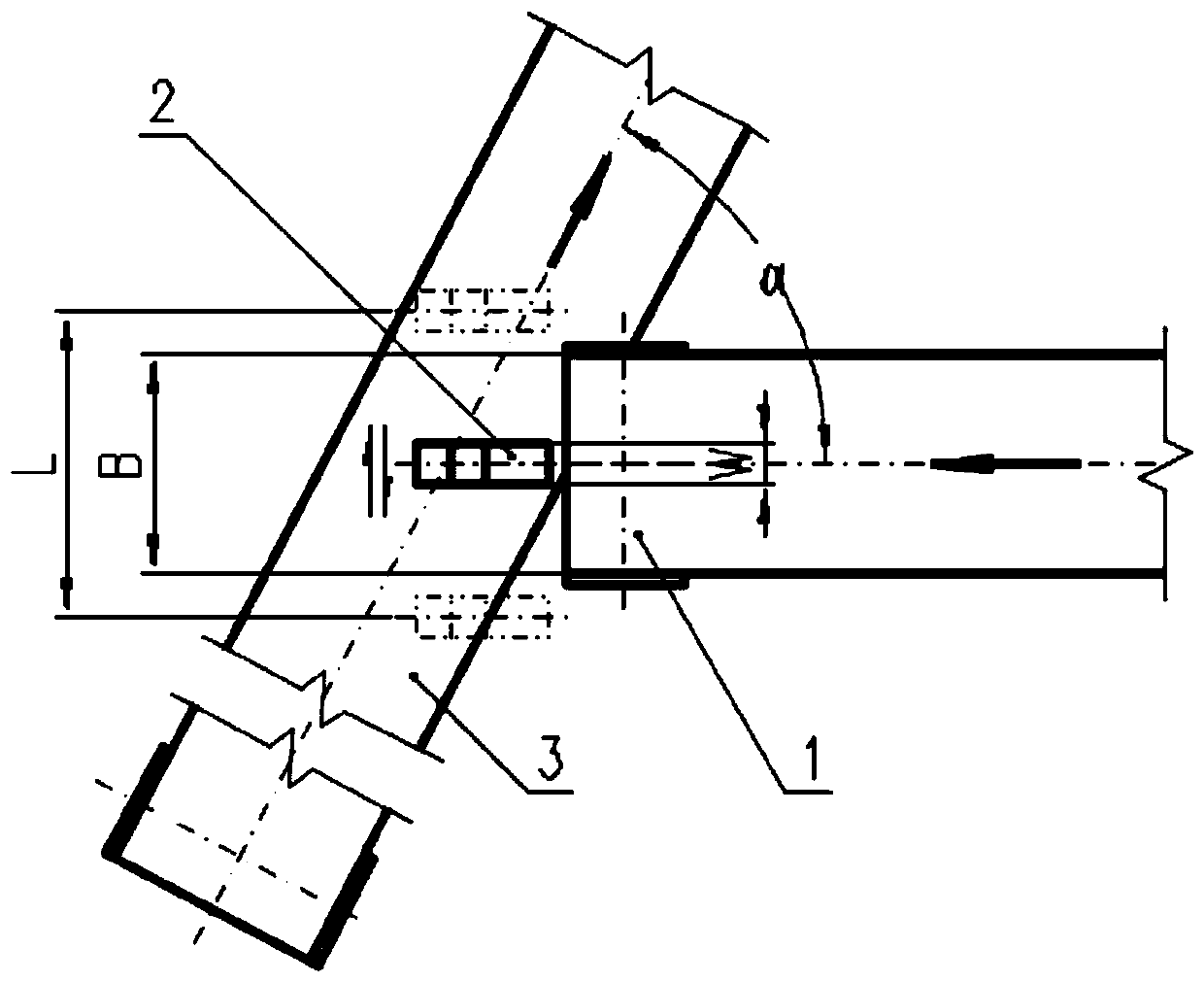

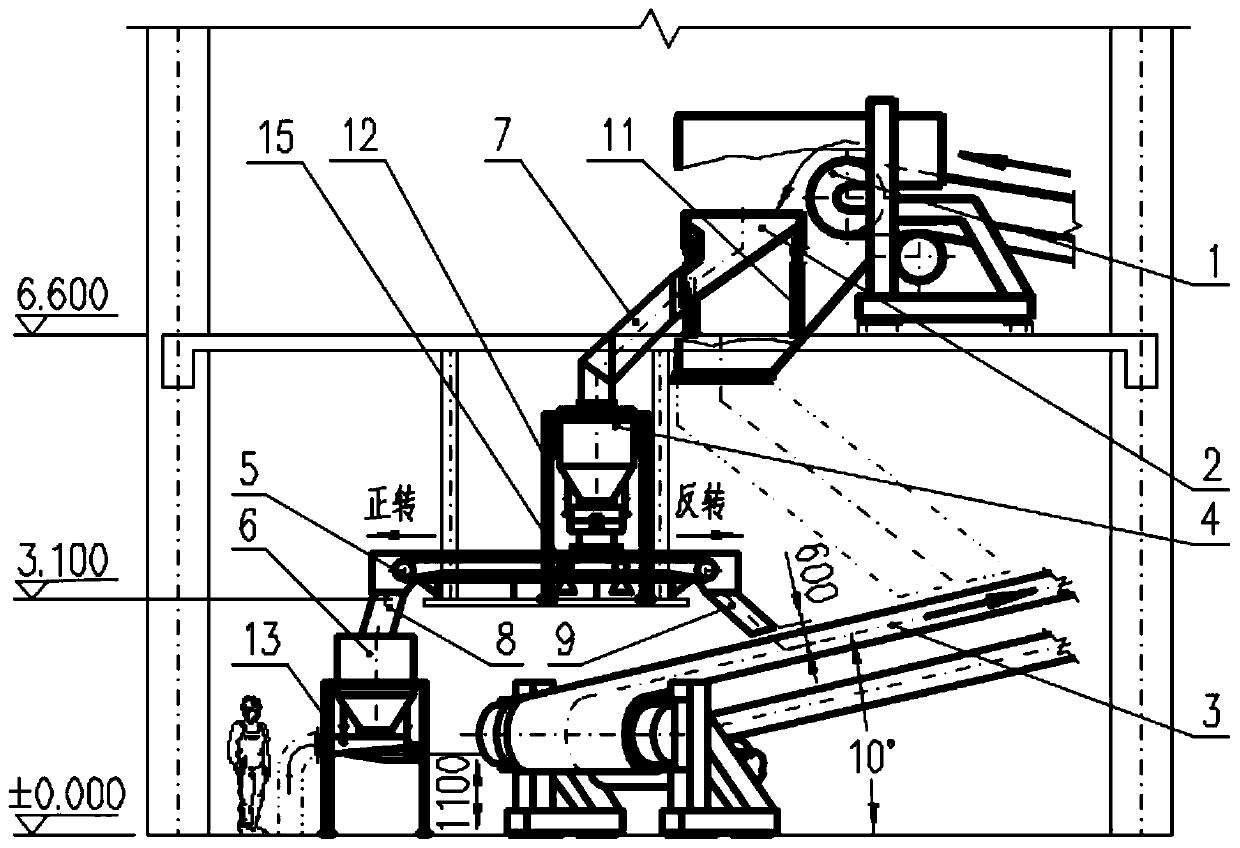

[0064] An on-line sampling and waste material recovery device, including a belt conveyor 1 under the tank, a sampling moving bucket 2, a main feeding belt conveyor 3, a sample weighing bucket 4, a reversible belt conveyor 5, and a sampling collection bucket 6; the main points of the technical solution : The head of the belt conveyor 1 under the tank is on the top, and the feeding section of the main belt conveyor 3 is on the bottom, which is the conventional transfer node of the logistics from upstream to downstream; the sampling mobile bucket 2 is arranged under the head of the belt conveyor 1 under the tank In the material flow area, reciprocate along the vertical material flow direction to collect samples; the upper part of the sample material weighing hopper 4 is connected with the sampling moving hopper 2; It is connected with the feeding main tape machine 3, and the sample is loaded into the sampling collection bucket 6, and the discarded material is put on the feeding ma...

example 1

[0071] The preparation method of example 1, concrete steps and parameters are as follows:

[0072] 1. The head of the tape machine 1 under the trough and the receiving section of the main feeding belt machine 3 below are conventional transfer nodes. The head of the tape machine 1 under the trough is connected to the 6.600m sampling platform, and the connection method is on the 6.600m platform Upper pre-embedded bolts are threaded through the head bracket; the receiving section of the feeding main tape machine 3 is connected to the ±0.000m discarding platform by pre-embedding the bolts on the ±0.000m platform and passing through the main feeding tape The frame of machine 3 is connected by thread; the 6.600m sampling platform and the ±0.000m sample discarding platform are conventional civil concrete structure platforms.

[0073] 2. The sampling mobile bucket 2 is connected to the 6.600m sampling platform. The connection method is to embed bolts on the 6.600m platform, and use th...

Embodiment 2

[0082]An on-line sampling and waste material recovery device, including a belt conveyor 1 under the tank, a sampling moving bucket 2, a main feeding belt conveyor 3, a sample weighing bucket 4, a reversible belt conveyor 5, and a sampling collection bucket 6; the main points of the technical solution : The head of the belt conveyor 1 under the tank is on the top, and the feeding section of the main belt conveyor 3 is on the bottom, which is the conventional transfer node of the logistics from upstream to downstream; the sampling mobile bucket 2 is arranged under the head of the belt conveyor 1 under the tank In the material flow area, reciprocate along the vertical material flow direction to collect samples; the upper part of the sample material weighing hopper 4 is connected with the sampling moving hopper 2; It is connected with the feeding main tape machine 3, and the sample is loaded into the sampling collection bucket 6, and the discarded material is put on the feeding mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com