A high-speed axially rotating heat pipe performance testing device and its working method

A technology of axial rotation and testing device, applied in the direction of measuring device, material thermal analysis, material thermal development, etc., can solve problems such as lack, and achieve the effect of reducing experimental cost and accurate and reliable results of heat pipe measurement experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

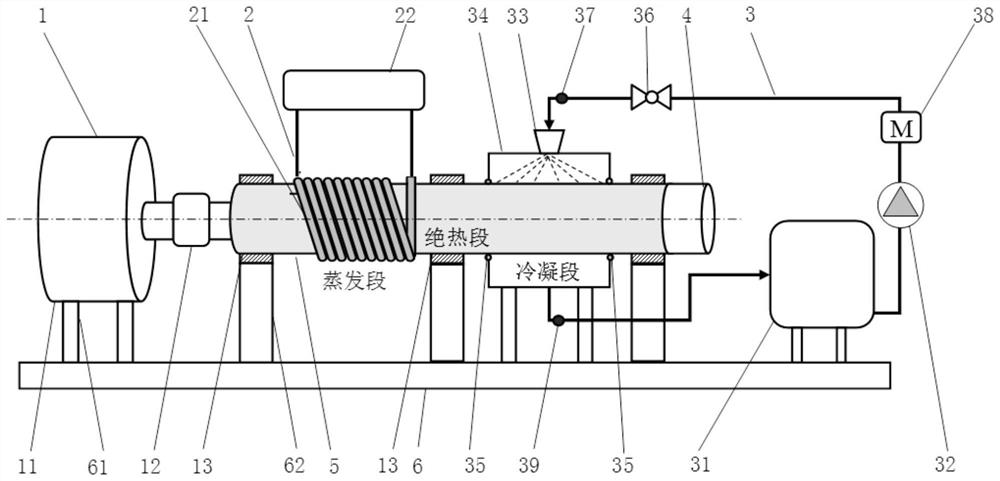

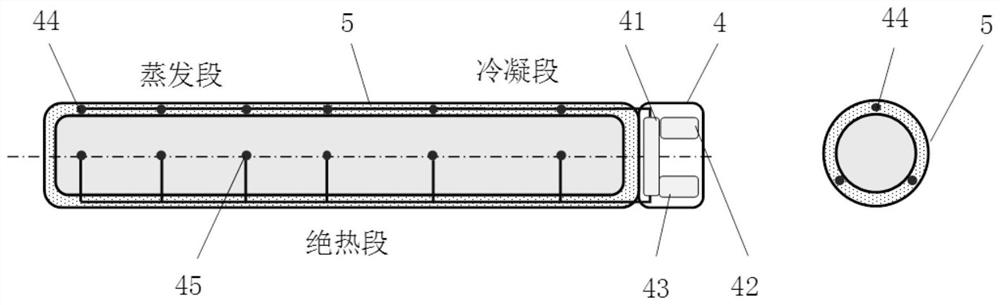

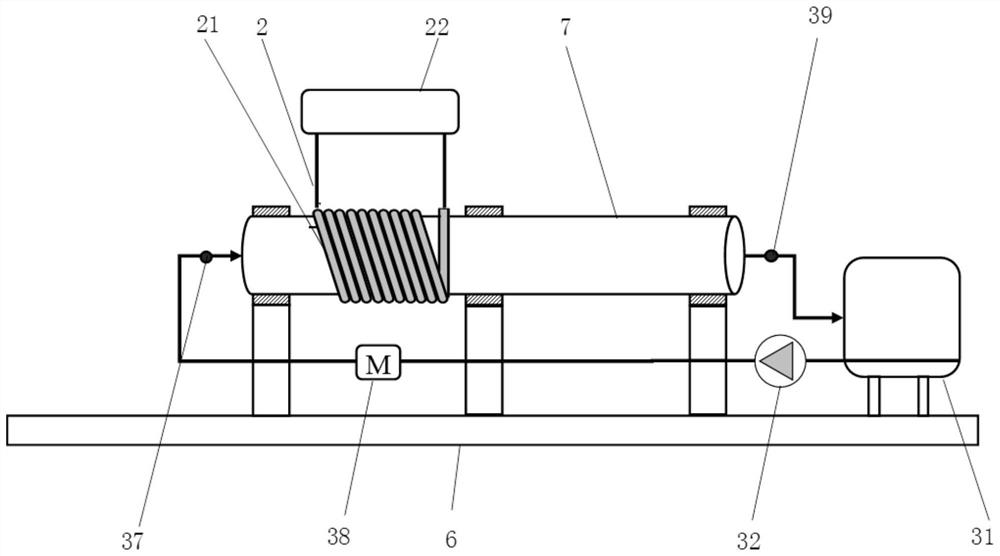

[0029] An embodiment of the present invention provides a high-speed axially rotating heat pipe performance testing device, such as figure 1 As shown, it includes: a rotating device 1 , a heating device 2 , a cooling device 3 , a wireless temperature measuring device 4 , a rotating heat pipe 5 to be tested and an experimental bench 6 .

[0030] The test bench 6 provides support for each part of the test bench, including a base, a motor base 61 and several bearing seats 62 . The experimental bench is placed on the working plane, and the motor base 61 and the bearing seat 62 are installed on the base. The motor 11 is installed on the motor base 61 , the output shaft of the motor 11 is connected to the measured rotating heat pipe 5 through the coupling 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com