Hub motor for directly driving urban rail bullet train wheels

A technology for in-wheel motors and urban rails, which is applied to transmission devices, electric components, and electromechanical devices driven by motors, can solve the problems of inability to reduce weight, loss of reduction gears, and huge volume, achieve safe work, eliminate magnetic loss, The effect of increasing the effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

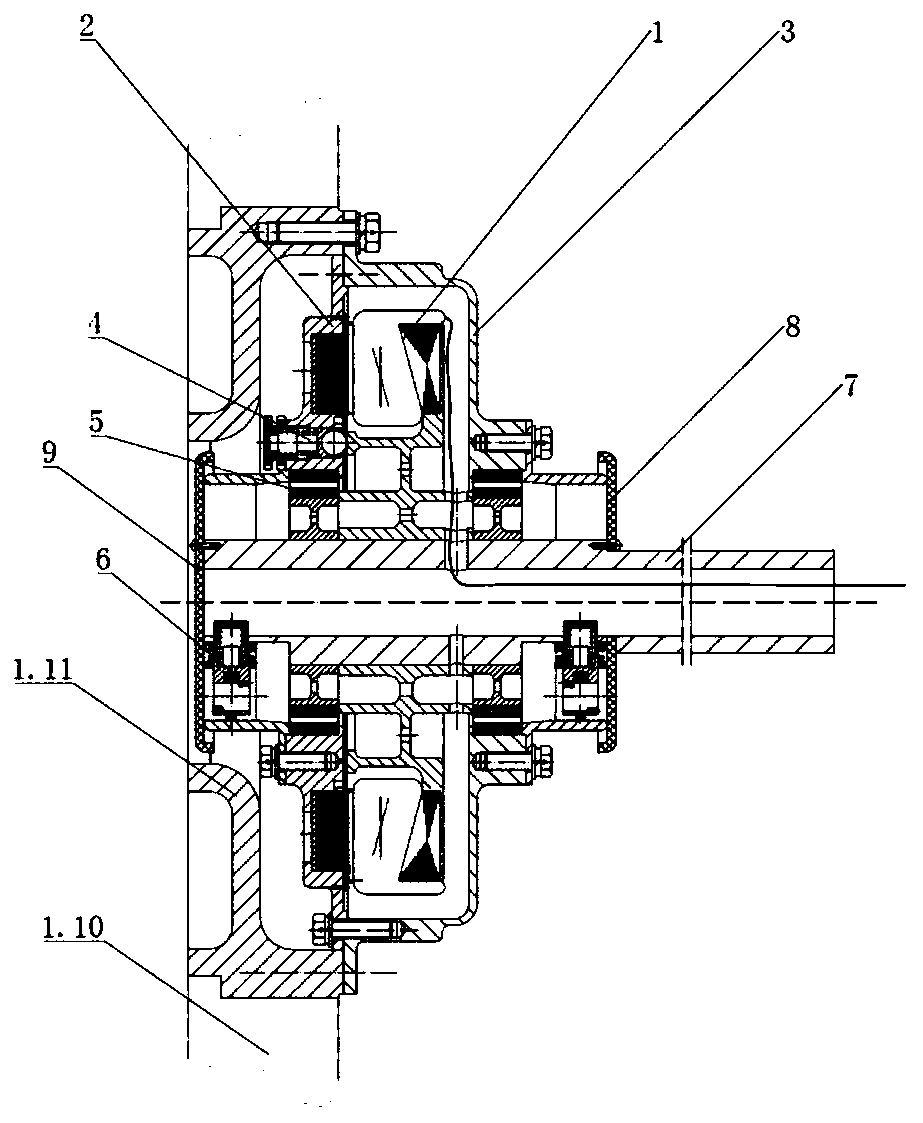

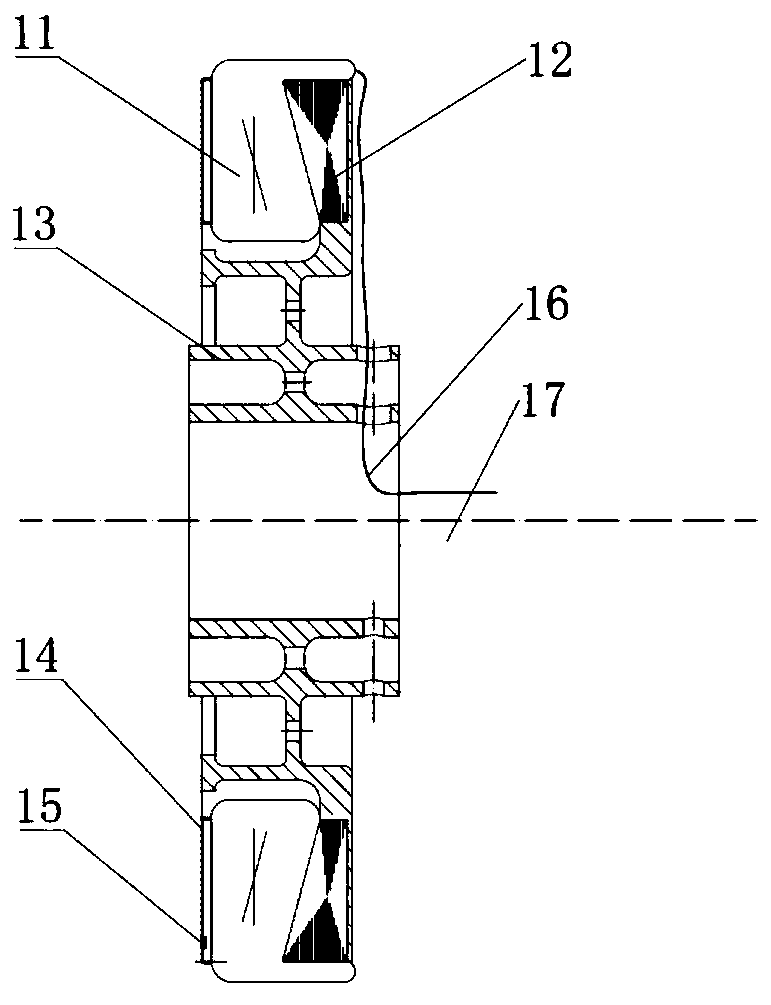

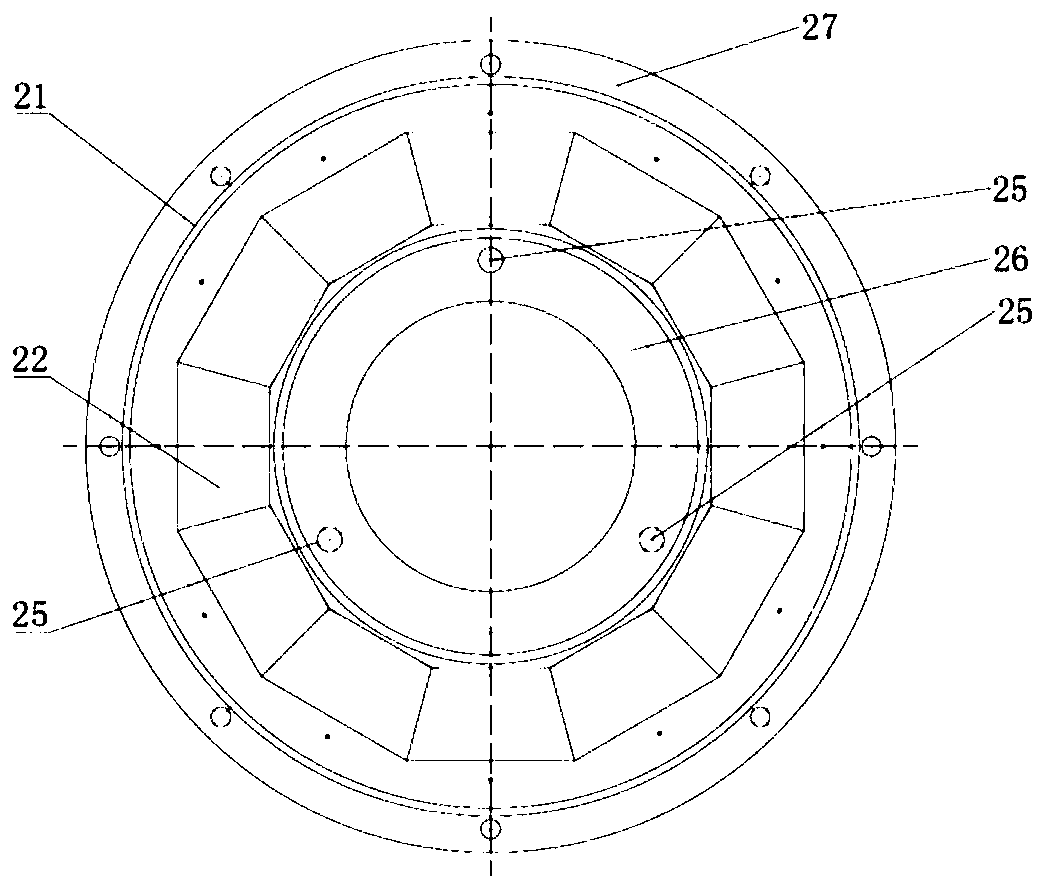

[0039] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. These descriptions are based on the selected motor vehicle wheel with an outer diameter of φ840mm as a model, and the design of the disc-driven hub motor. But it does not limit the application of the present invention to any other types of urban rail trains, and the matching of wheels of motor vehicles with different outer diameters. Popularization and application need to be in accordance with the technical indicators required by the train, such as: the outer diameter of the train wheel; the maximum speed of the train; the voltage of the power supply; the maximum torque required for the train to start (the total mass of the train when the train is the largest passenger load), etc. . Determine the technical parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com