Motor insulation drying cabinet with double-suspension-door structure

A drying cabinet and suspension technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of increasing workload and maintenance time, unable to meet the assembly of heating parts, time-consuming, etc., and achieve maintenance labor efficiency and safety. The effect of improving the performance, saving the space occupied by the transportation platform, and simple and convenient mobile transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] At present, the heating component placement method of the heating cabinet has not been developed and developed in the industry, especially the heating and drying of heavy or super heavy motor parts. Due to the limitation of the side door structure of the traditional heating cabinet, it is not possible to directly use the hoisting method to put the heating component into the heating. In the cabinet, the specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

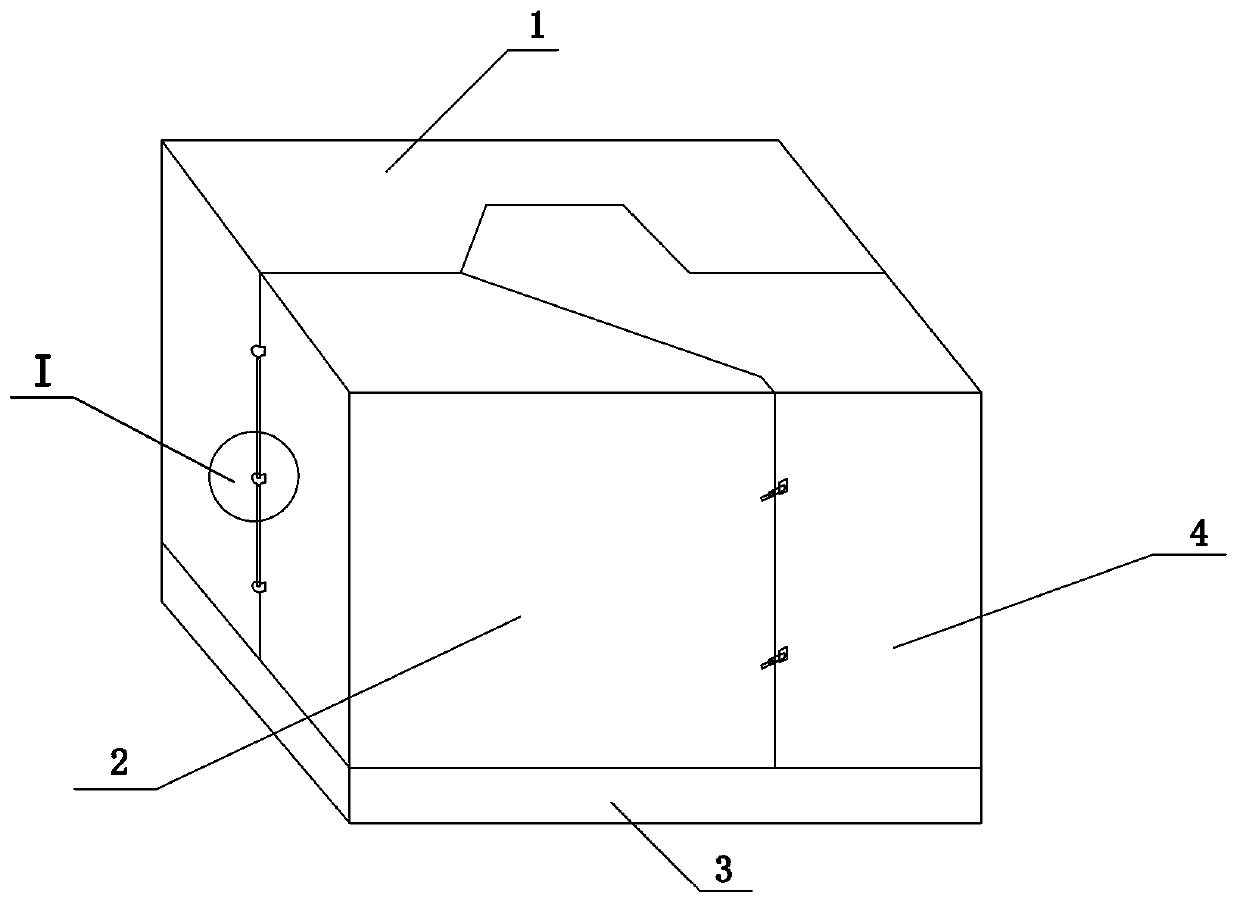

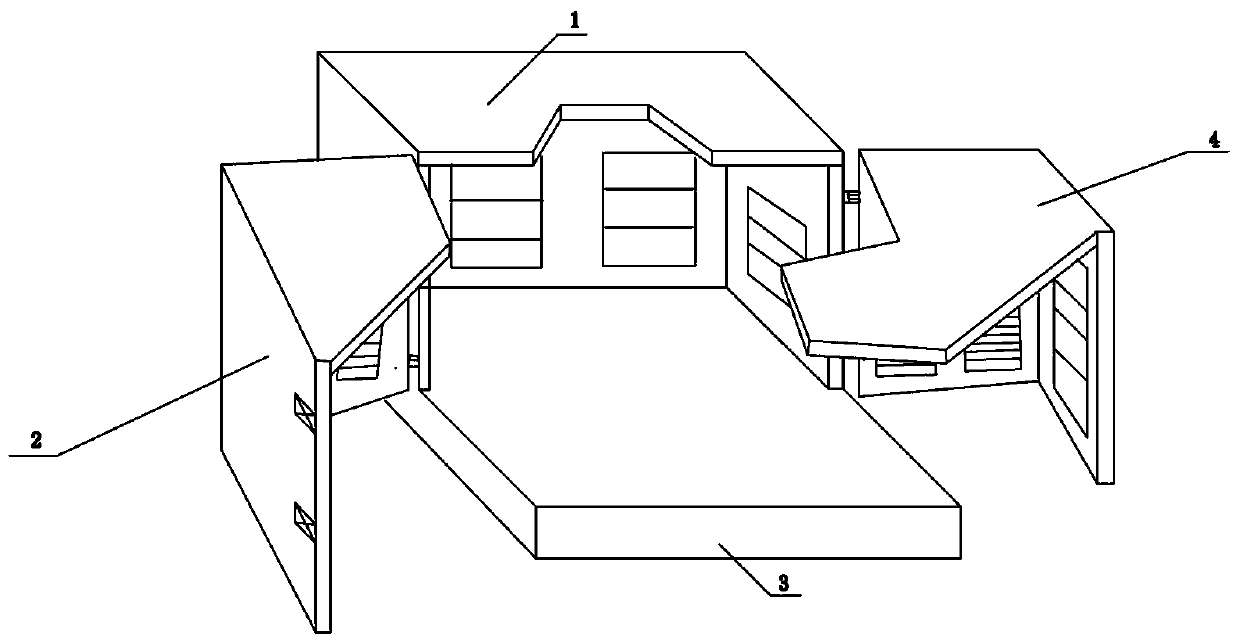

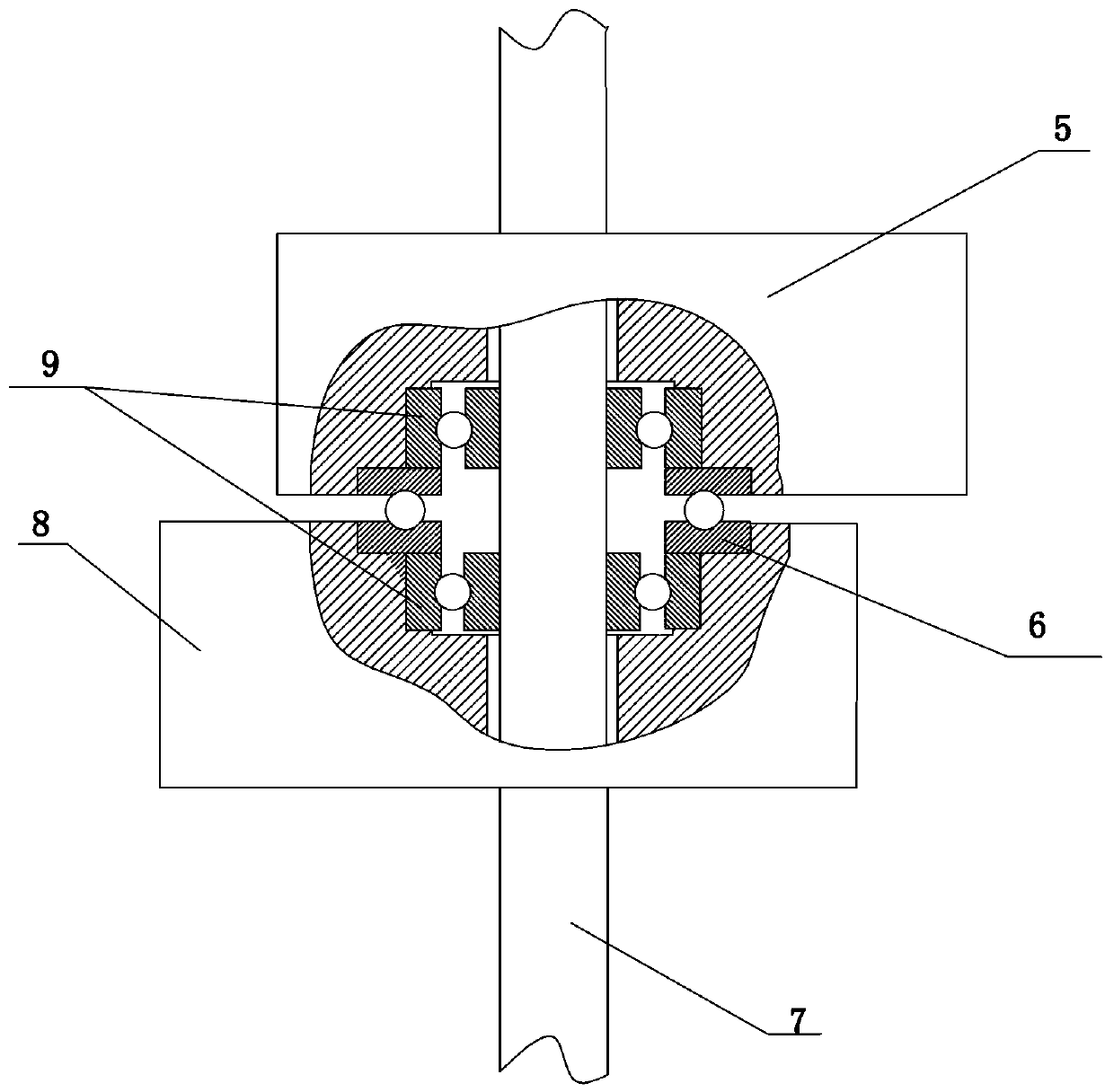

[0029] Such as Figure 1-6 As shown, the motor insulation drying cabinet with double-hung door structure of the present invention is characterized in that it includes a concave body of the heating cabinet, and a chamfered suspension door 2 connected to the concave body of the heating cabinet through a one-way thrust floating door shaft. and a convex suspension door 4, the concave body of the heating cabinet includes a box body, a concave ceiling 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com