Water hammer pressure signal conditioning device suitable for LMS collection system

A pressure signal and signal conditioning technology, applied in the direction of DC-coupled DC amplifiers, differential amplifiers, etc., can solve the problems of small measurement channel capacity, low signal acquisition frequency, single system function, etc., to reduce work costs, optimize systems and personnel Configure and realize the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

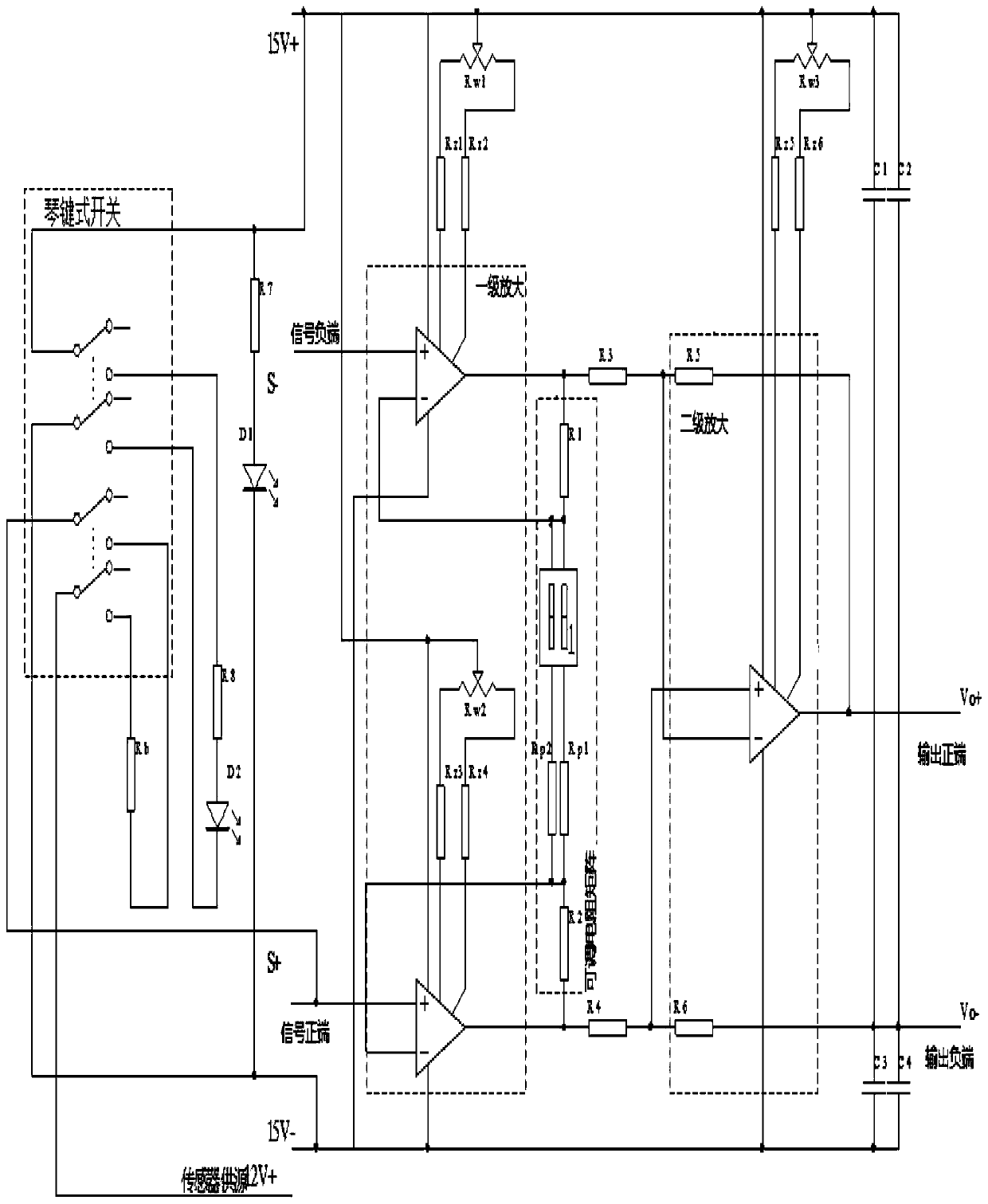

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

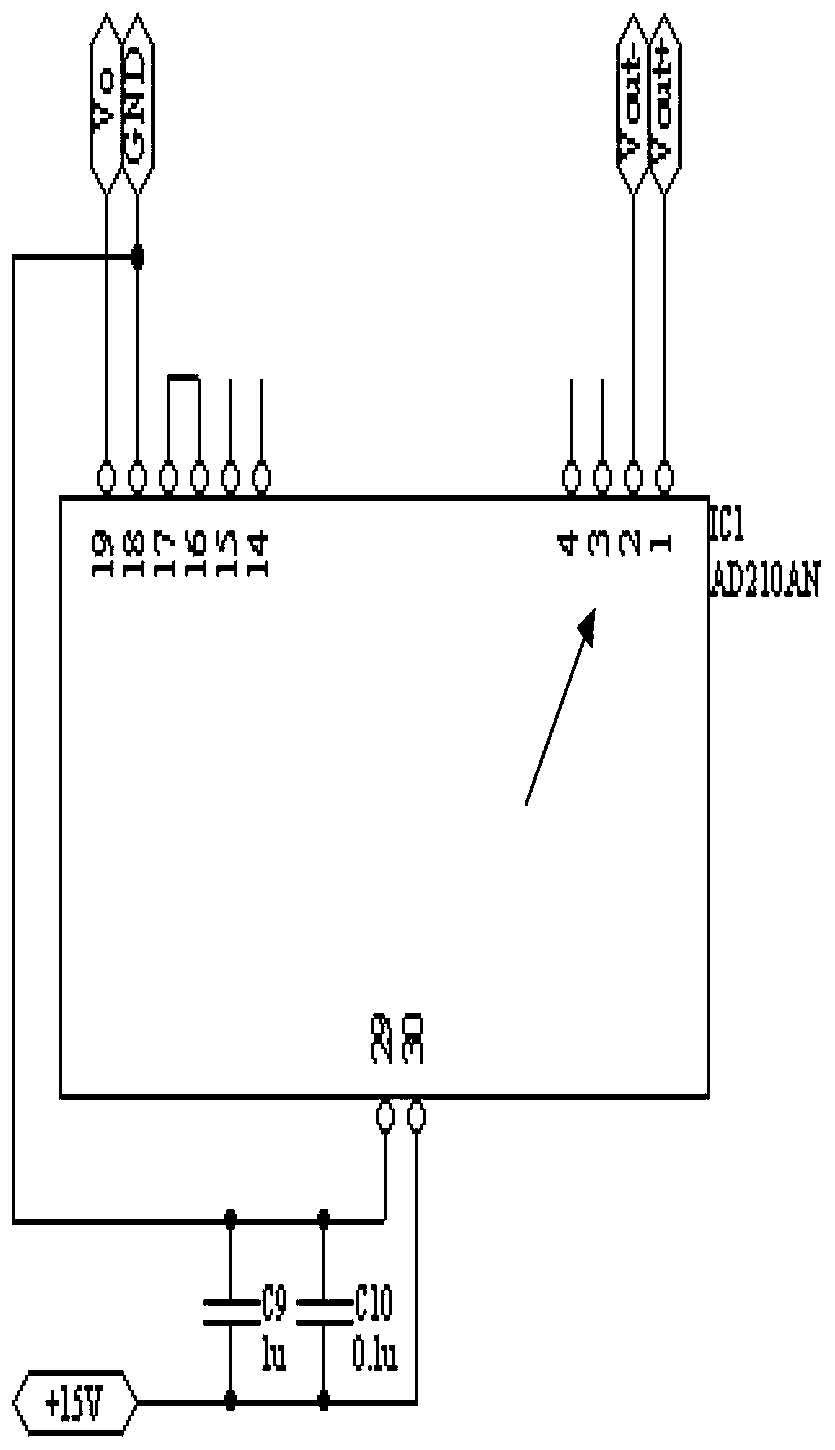

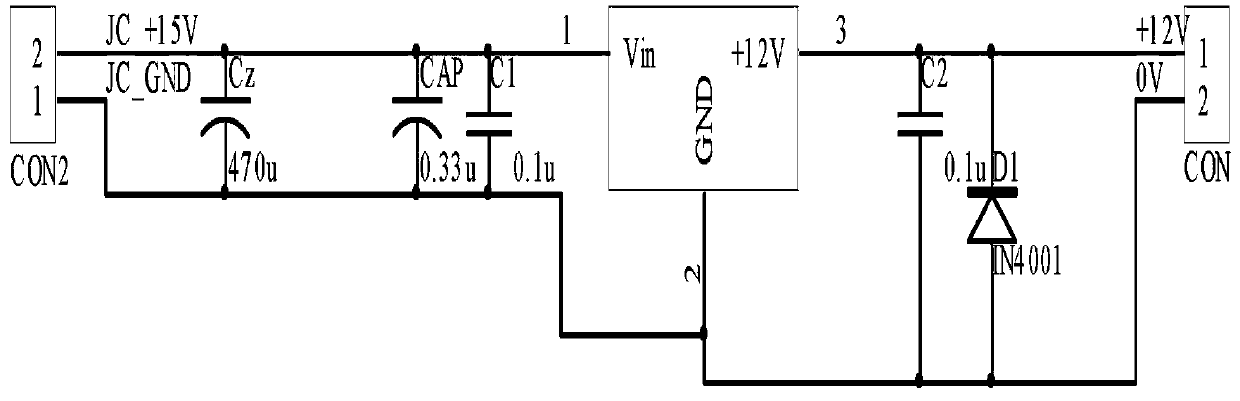

[0032] This embodiment is applicable to the water shock pressure signal conditioning device of the LMS acquisition system, which includes a main box. The main box is provided with a signal conditioner motherboard and a signal conditioning board, and the signal conditioner motherboard is provided with 6 signal conditioning boards. Slot, through which the signal conditioning board is fixed on the signal conditioning motherboard. In consideration of flexible use and convenient replacement, the signal conditioning board is designed as a gold finger connection. At the same time, referring to the length of the standardized chassis guide rail and fully considering the matching size of the connector, the size of the signal conditioning board is selected as: 100mm (height) × 164mm (length), the plate thickness is 1.6mm.

[0033] The motherboard of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com