Cleaning and drying device for machining

A drying device and mechanical processing technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of easy rusting of workpieces, achieve the effects of reducing bumps, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

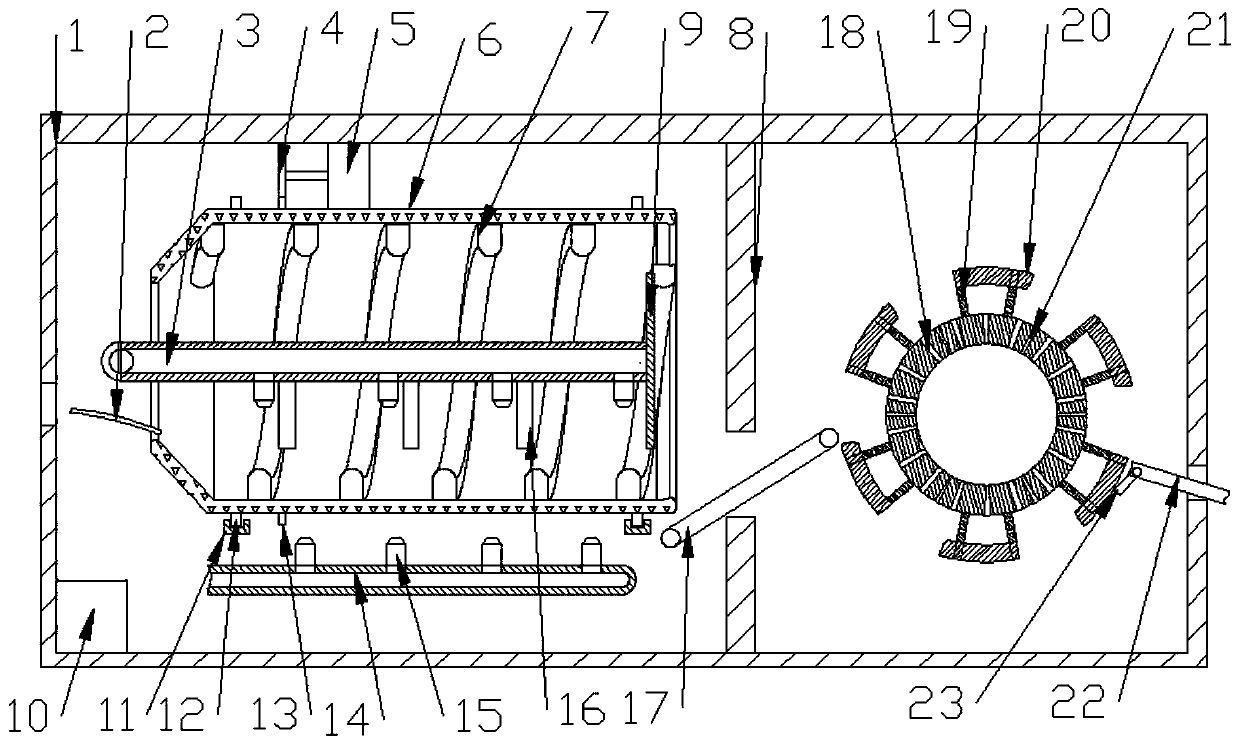

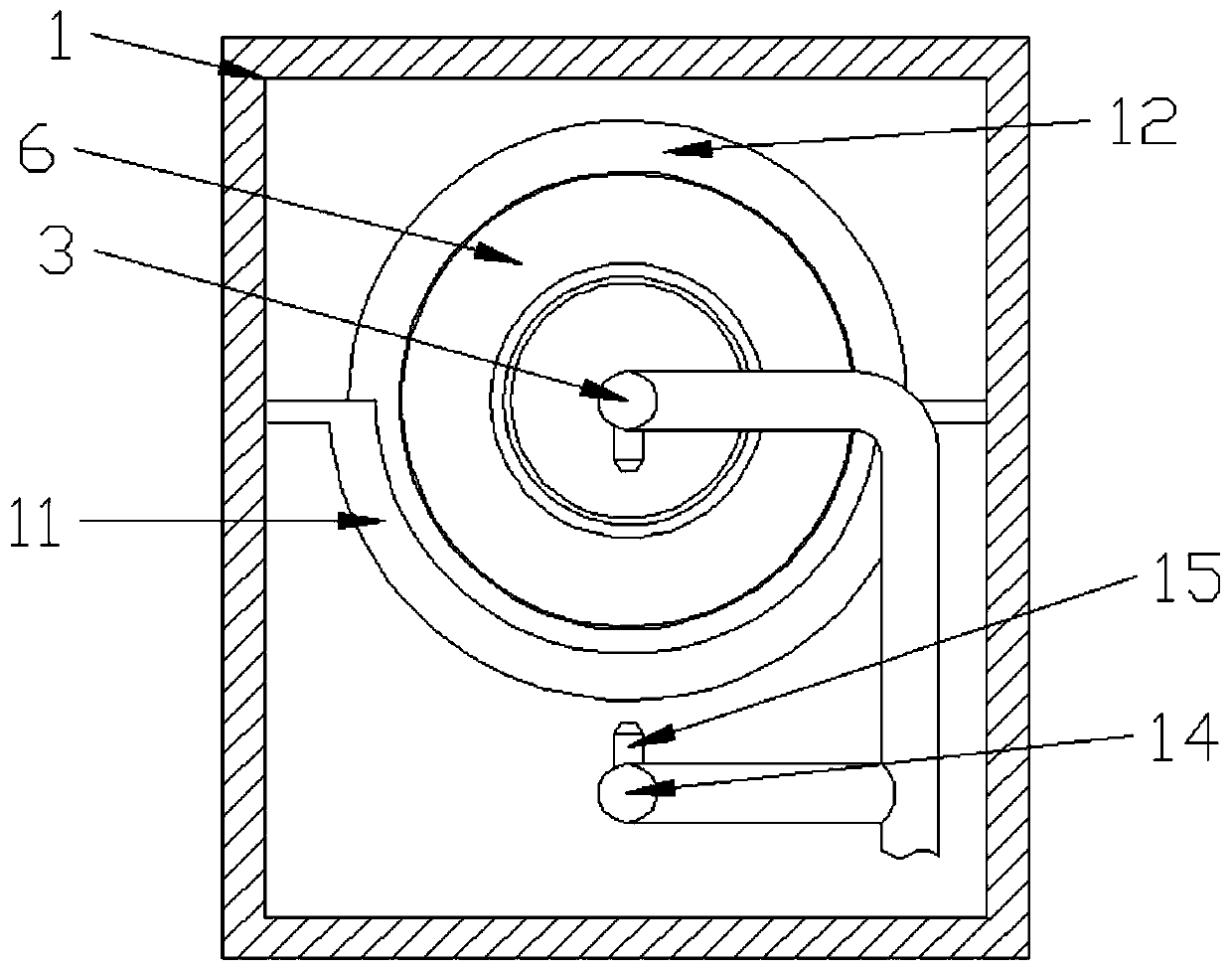

Embodiment 1

[0025] see Figure 1-4 , the present embodiment provides a cleaning and drying device for mechanical processing, including an outer shell 1, a feed plate 2, a cleaning mechanism and a drying mechanism are arranged in the outer shell 1, and the cleaning mechanism and the drying mechanism are There is an intermediate partition 8 between them. The cleaning mechanism includes a pump body 10, a cleaning cylinder 6 and a seat ring 11. The seat ring 11 is semicircular in shape and its upper end extends to both sides with a cross bar fixedly connected to the On the inner wall of the outer casing 1, a chute is provided on the seat ring 11, the cleaning cylinder 6 is a hollow structure and a collar 12 is arranged on it, the collar 12 is located in the chute, and the cleaning cylinder 6 6 is provided with a spiral plate 7 and a water pipe 14 is provided below it. The water pipe 14 is provided with a number of nozzles 15 facing the cleaning cylinder 6. The end of the cleaning cylinder 6 a...

Embodiment 2

[0031] On the basis of Embodiment 1, a central pipe 3 is arranged in the cleaning cylinder 6, and the central pipe 3 communicates with the water pipe 14, and several nozzles 15 are arranged below the central pipe 3, so that the inside and outside are washed together. , the cleaning effect is better. Several brush heads 16 are also arranged on the central tube 3 , and the central tube 3 is fixedly arranged, so that the cleaning effect can be enhanced by the brush heads 16 during the rotation of the cleaning cylinder 6 . The end of the central pipe 3 away from the feed plate 2 is provided with a shielding plate 9, which can prevent the cleaning liquid in the cleaning cylinder 6 from splashing to the drying mechanism.

Embodiment 3

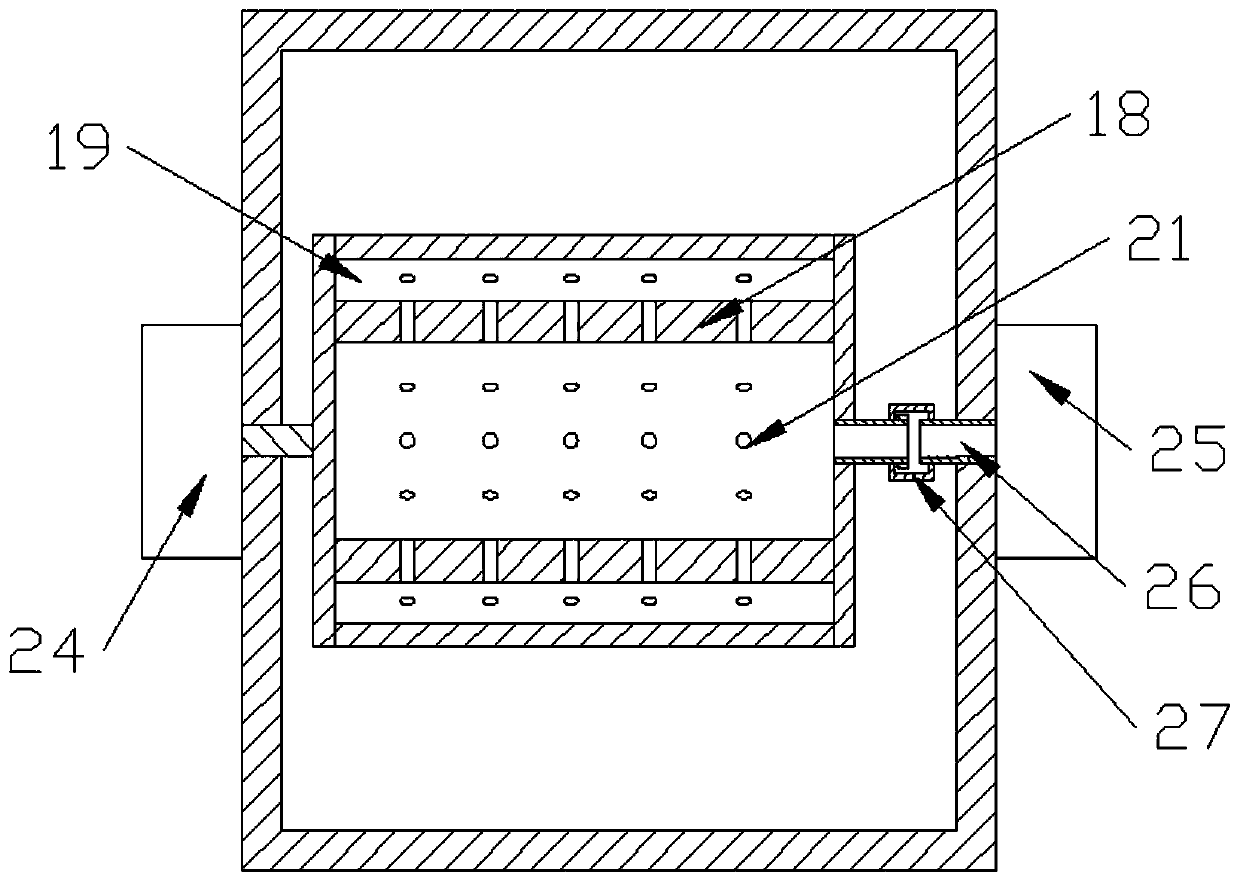

[0033] see Figure 5 , on the basis of Embodiment 1, an external sleeve 28 is also provided. The external sleeve 28 is connected to the inner wall of the outer casing 1 and has a corresponding opening on it. During the process, the workpiece falls, and at the same time, the space in the outer sleeve 8 is smaller, which is conducive to improving the drying effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com