High-performance low-zinc brass alloy wire coiling device for electronic communication

A low-zinc brass and alloy wire technology, applied in the field of brass alloy wire take-up devices, can solve problems such as difficult separation, uneven take-up of the take-up device, messy purple brass alloy wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

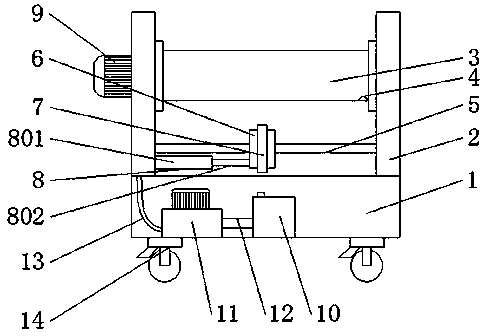

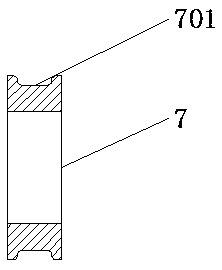

[0018] refer to figure 1 figure 2 , a high-performance low-zinc brass alloy wire take-up device for electronic communication, including a control cabinet 1, support columns 2 are fixedly connected to the left and right sides of the upper surface of the control cabinet 1, and a take-up shaft is installed between the two support columns 2 3. Both ends of the take-up shaft 3 are rotatably connected to the inner surfaces of the two support columns 2 through bearings, and the take-up shaft 3 is provided with a fixing hole 4; the guide rod 5 is located below the take-up shaft 3, and the two ends of the guide rod 5 are fixedly connected On the inner surface of the support column 2; the guide rod 5 is slidingly sleeved with a guide block 6, and the outer surface of the guide block 6 is coaxially connected with a pulley 7, and the outer surface of the pulley 7 is provided with a groove 701; the cylinder of the hydraulic cylinder 8 The sleeve 801 is fixedly connected to the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com