A process method of zero-taper through-hole for transparent brittle material

A technology of brittle materials and through-hole technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., to achieve the effect of improving thermal damage, reducing device cost, and improving processing pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

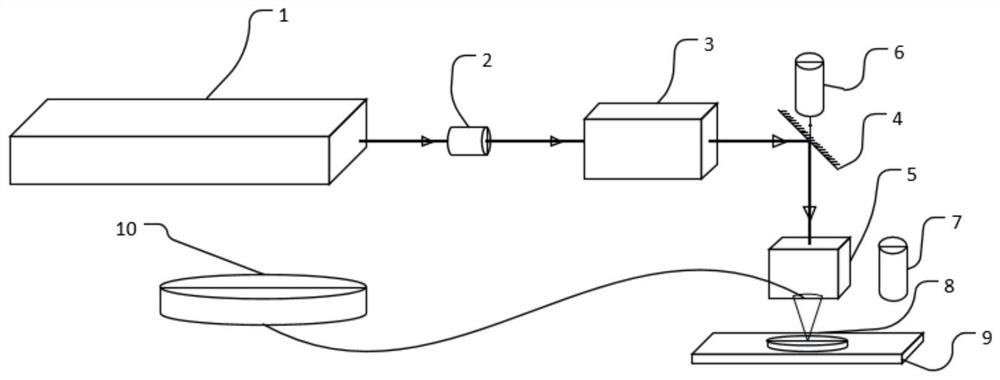

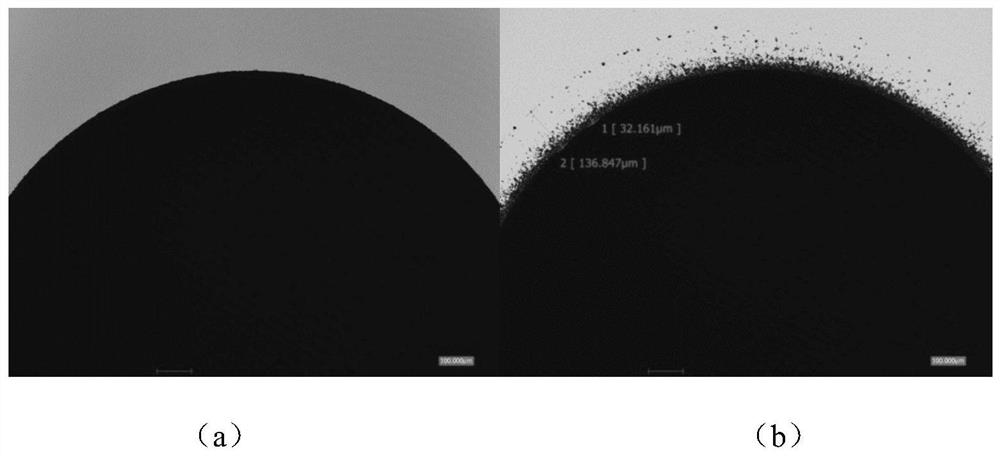

[0047] This embodiment provides a process method for a zero-taper through hole of a transparent brittle material, which is realized by a processing device for a zero-taper through hole of a transparent brittle material. In this embodiment, a through hole with a diameter of 1.68 mm is processed on sapphire with a processing thickness of 0.3 mm by using the device and method described above.

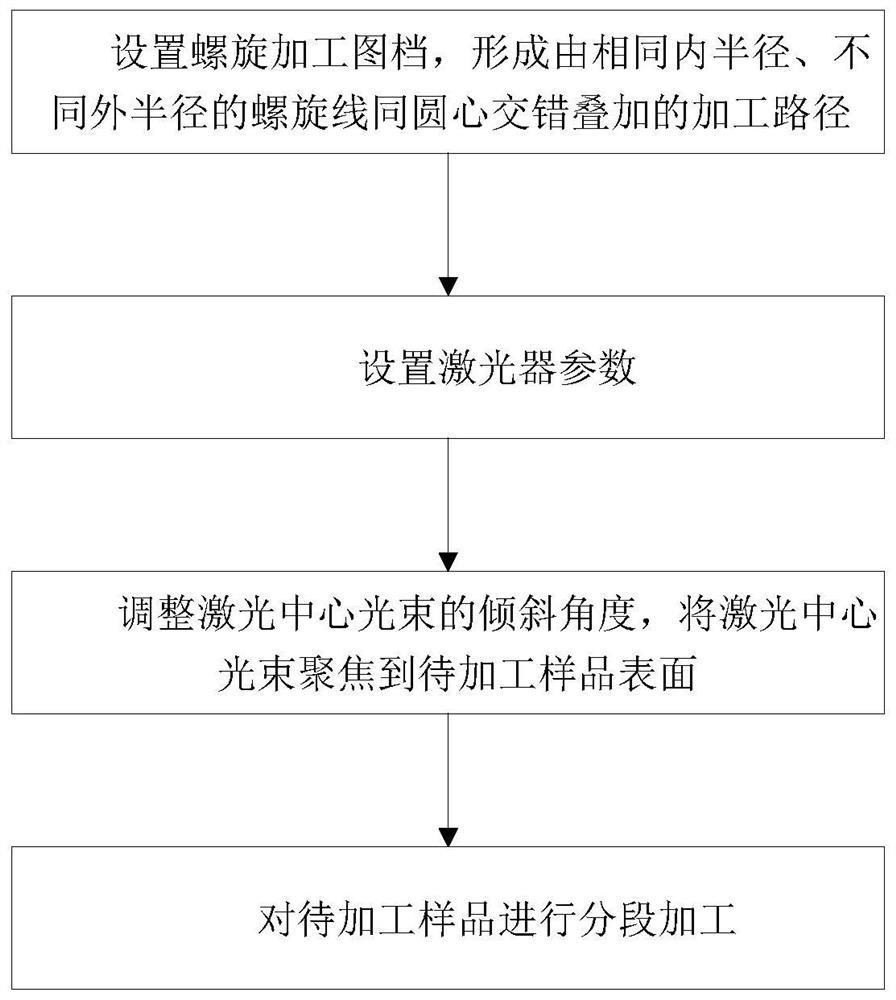

[0048] Specific steps are as follows:

[0049] Step 1. Set the required processing image files through the laser control system. In order to achieve the technical effect described in the present invention, the processing image is composed of helical lines with the same inner radius of 1.68 mm and different outer radii interlaced with the center of the circle. The minimum outer radius of the different helixes is 1.925mm, and then the outer radius is increased to 2.125mm in steps of 0.015mm, and there are 13 sets of helixes in total. The pitches of the helixes with different outer radii ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com