Circuit capable of eliminating electrolytic copper foil surface processor high frequency switch power supply eddy current and method thereof

A high-frequency switching power supply, surface treatment machine technology, applied in electrolysis process, electroforming, electrical components, etc., can solve the problems of increasing production and maintenance costs, bulky processor, and inability to completely eliminate eddy current phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

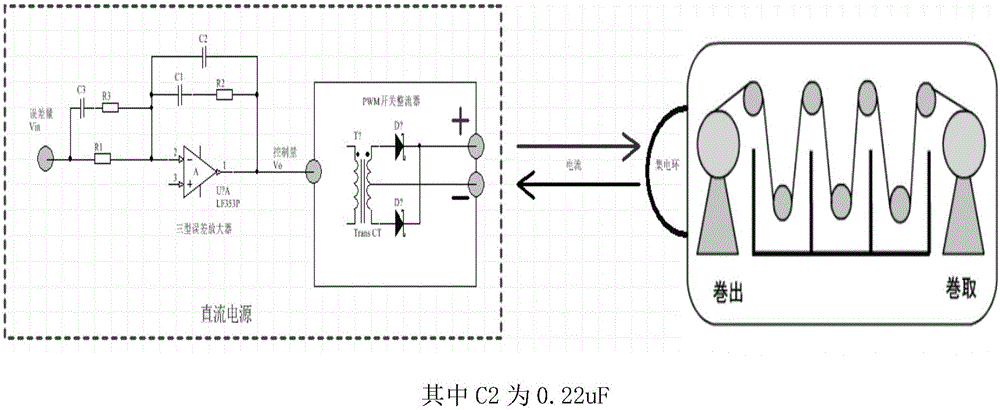

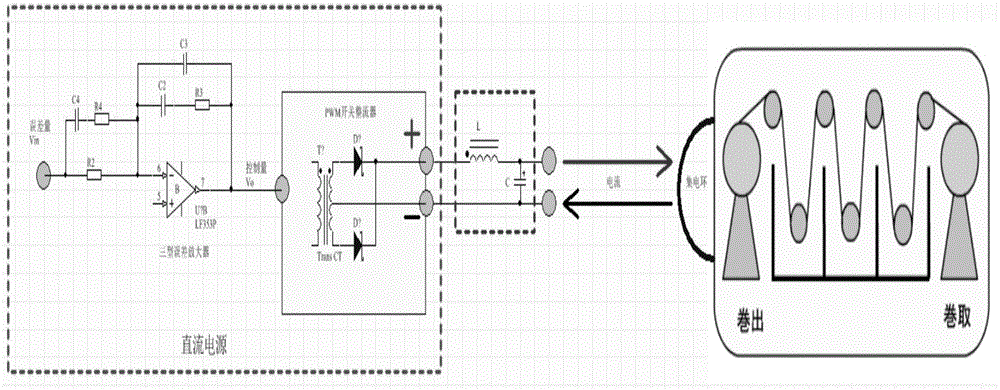

[0014] In the surface treatment of electrolytic copper foil, the power supply DC power supply outputs a current with high-frequency ripples, which is connected to the collector ring of the post-processing equipment through a cable. The DC power supply includes a three-type error amplifier and a PWM switching rectifier. After the current is amplified by the three-type error amplifier, it is input to the PWM switching rectifier for current leveling adjustment, and then output to the collector ring for post-processing of the copper foil.

[0015] During use, it was found that the collector ring bearing seat of the copper foil surface treatment machine was heated, and the temperature rise was as high as 100 degrees Celsius, which was an important factor affecting the normal operation of the post-processing line. The reasons for the analysis are as follows:

[0016] The automatic control system of the reel in the post-processing process of electrolytic copper foil has its inherent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com