Low speed die-stamping pin assembly for punching LTCC raw porcelain slice for electronic product and processing technology thereof

A technology of electronic products and processing technology, applied in the field of microelectronics, to achieve the effect of convenient processing, less damage, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

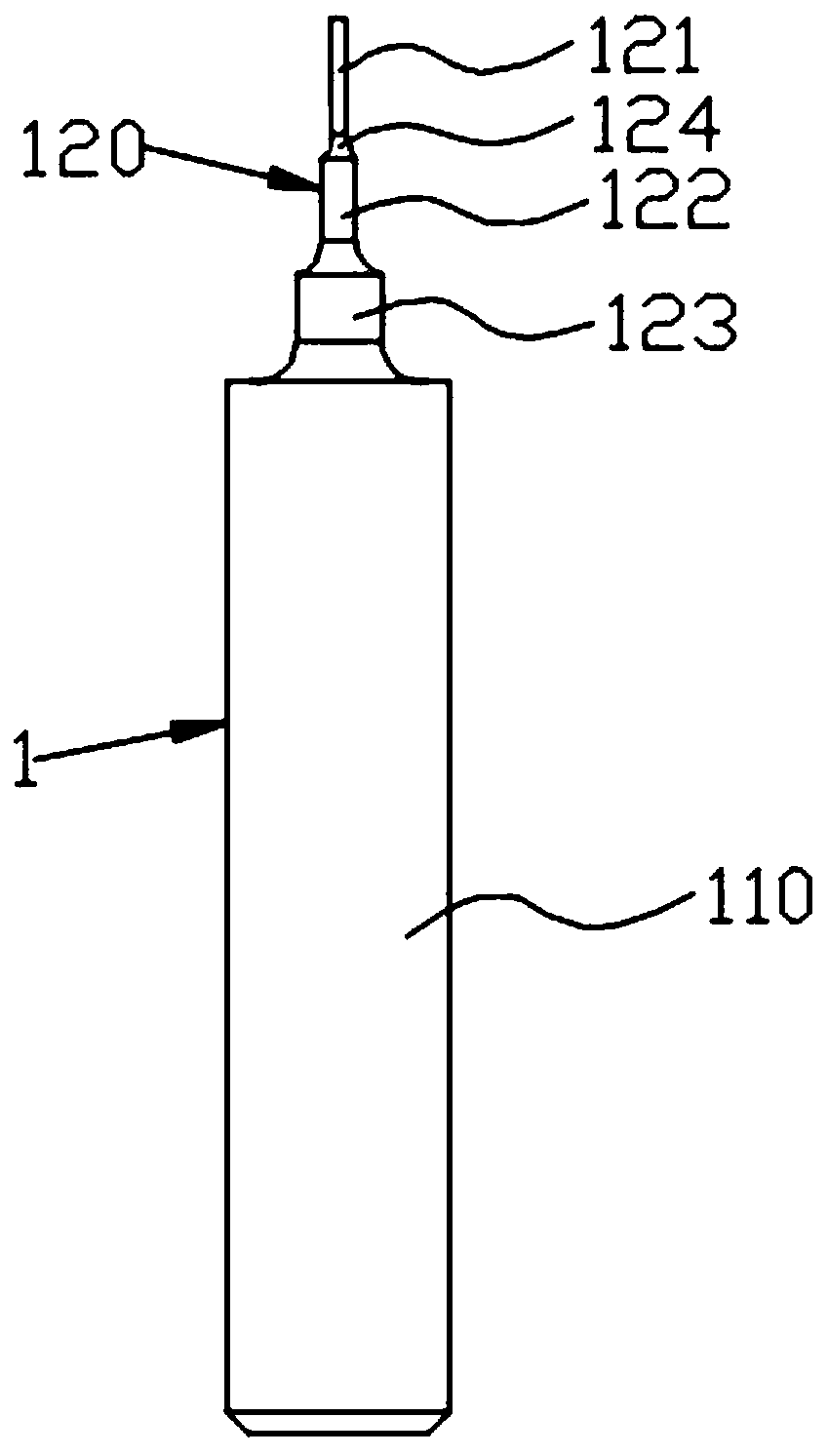

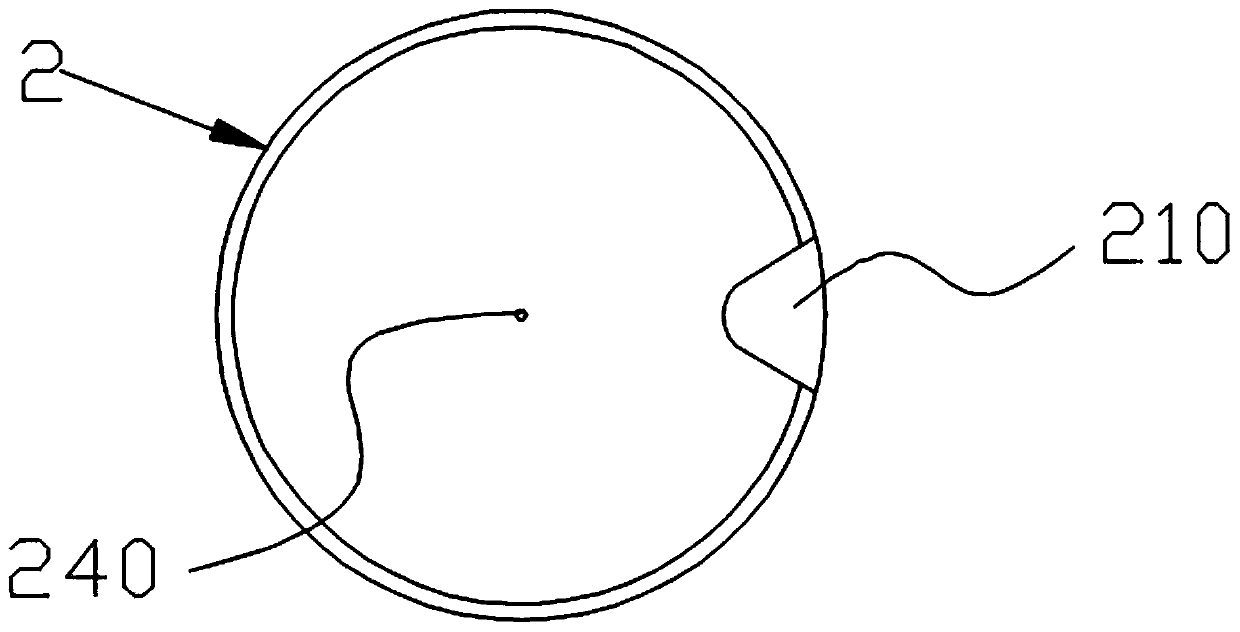

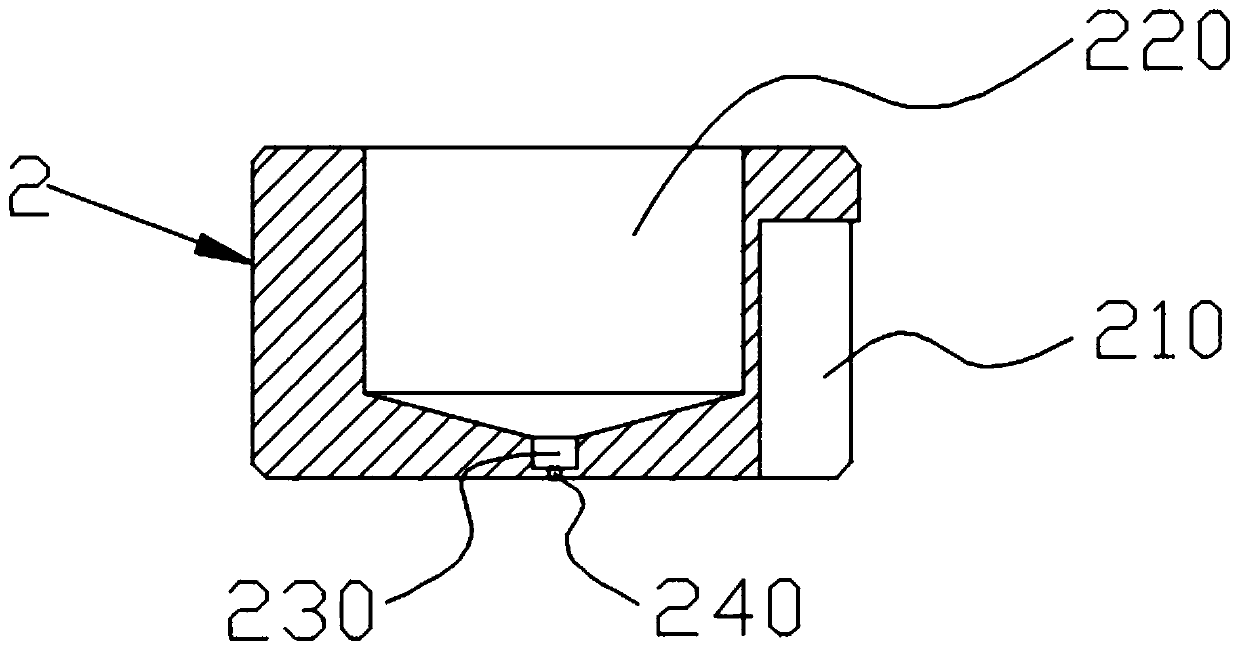

[0036] Such as Figure 1-Figure 3 As shown, a low-speed punching pin assembly for punching holes with LTCC green ceramic sheets for electronic products includes a low-speed punching pin 1 and a low-speed lower die 2. The low-speed punching pin 1 includes a punching body 110 and a The needle head 120 at one end of the needle body 110, the needle head 120 includes a first needle head portion 121, a second needle head portion 122 and a third needle head portion 123 connected in sequence, and the third needle head portion 123 is connected to the punch The needle body 110 is connected, and the diameters of the first needle head 121, the second needle head 122, and the third needle head 123 become larger in turn; the lower mold 2 of the low-speed mold is cylindrical, and one part of the lower mold 2 of the low-speed mold The end face is provided with a first receiving groove 220, and the bottom of the first receiving groove 220 is provided with a second receiving groove 230 for acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com