A method for improving edge strength of polyamic acid film

A technology of polyamic acid and polyamic acid resin, which can be used in other household appliances, coatings, flat products, etc., can solve the problem that the yield of polyamic acid resin is not improved, and can accelerate the imidization closed loop. Reactive, non-degradable, mechanically enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Weigh each component according to the following weight ratio, mix and stir evenly, and obtain the coating liquid;

[0028] 80 parts of DMAC, 20 parts of DMP-30, 0.5 parts of 1,3,5-tris(4-aminophenoxy)benzene, and 1 part of triphenyl phosphite;

[0029] 2) Add 22kg of ODA, 11.3kg of PDA and 320kg of DMAC in the reactor, add 46.5kg of PMDA after dissolving (adding in 3 times), react at room temperature for 5h, and obtain a polyamic acid resin with a viscosity of 200,000 centipoise solution, which is transported to a defoaming kettle for defoaming, to obtain a defoamed polyamic acid resin solution;

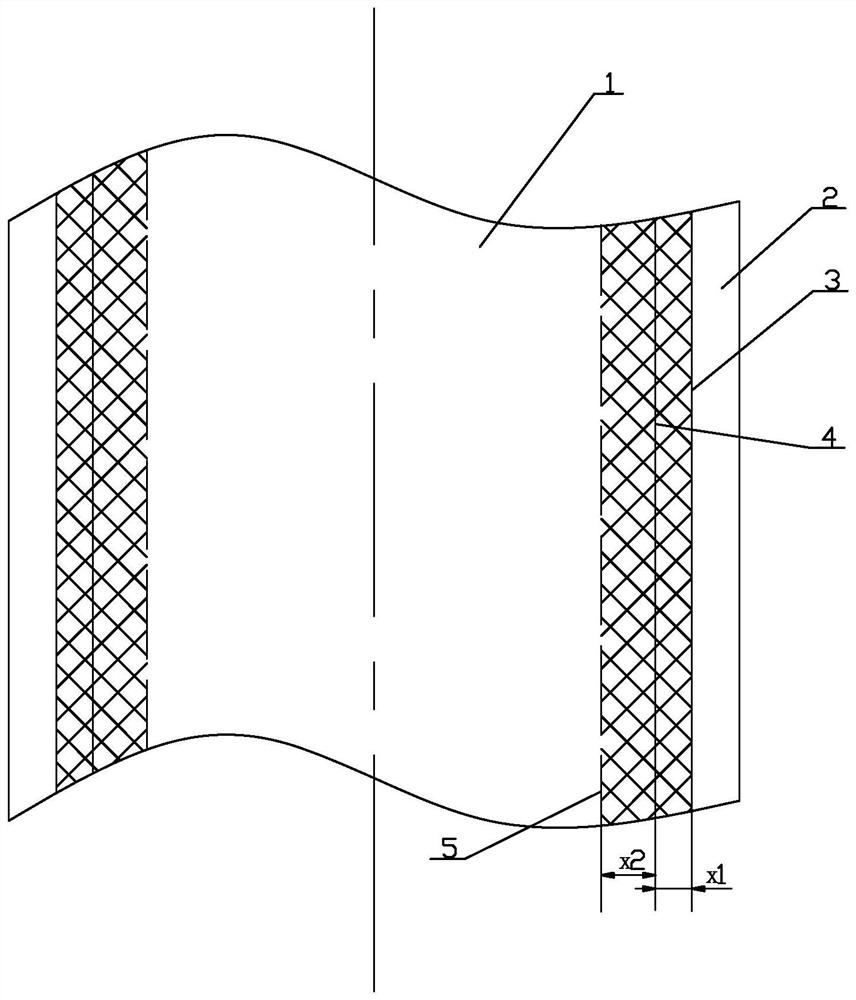

[0030] 3) Set the temperature of the drooling upper drying tunnel to 180°C, and the temperature of the lower drying tunnel to 190°C, first coat the coating solution on the steel strip, and then pour the defoamed polyamic acid resin solution onto the steel strip (i.e. During the whole drooling process, before the resin solution falls onto the steel strip each time, the corr...

Embodiment 2

[0041] 1) Weigh each component according to the following weight ratio, mix and stir evenly, and obtain the coating liquid;

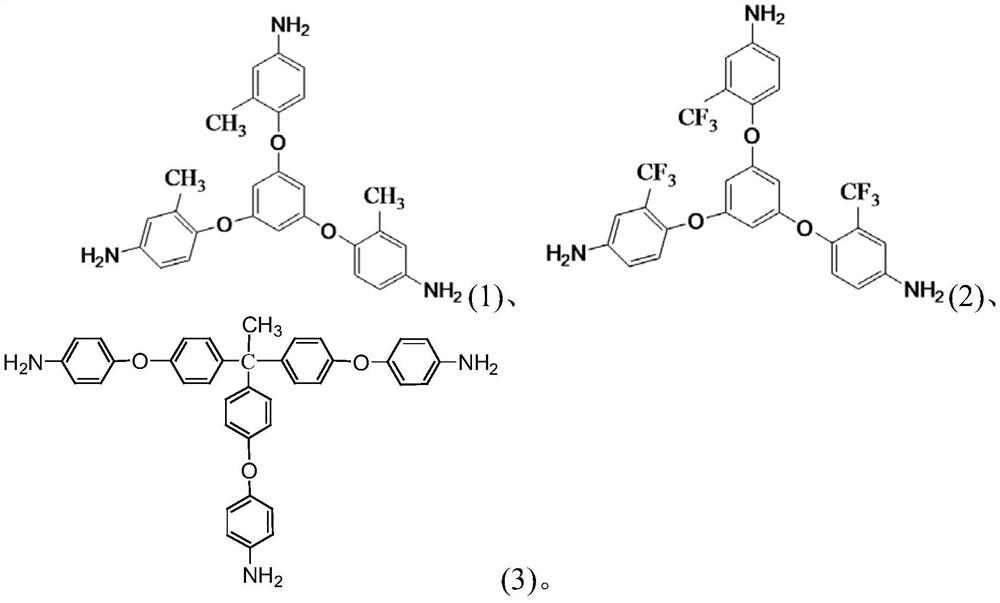

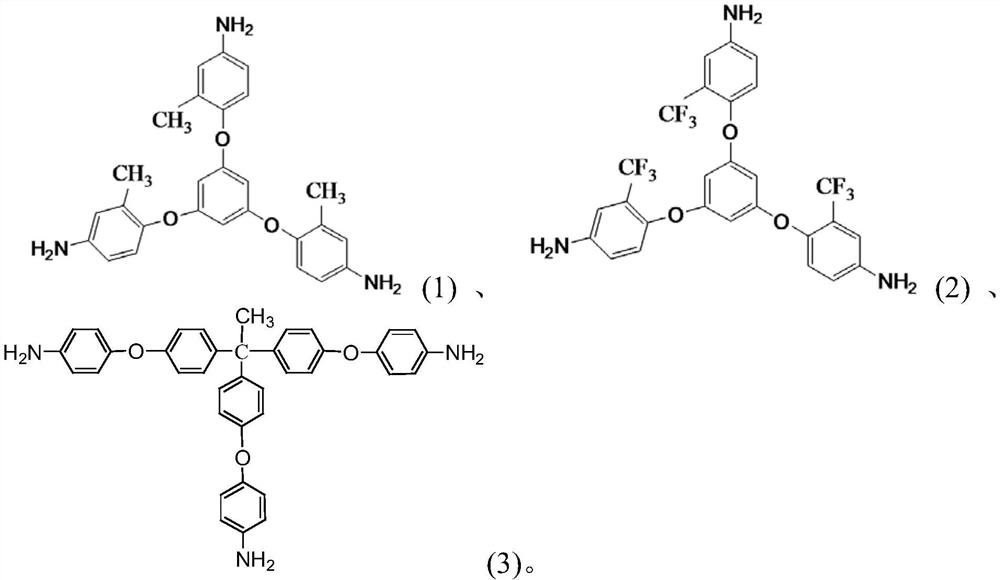

[0042] 70 parts of DMF, 15 parts of DMP-30, 1 part of triprimary amine crosslinking agent represented by formula (1), 0.5 part of triphenyl phosphite;

[0043] 2) Add 21.5kg of p-phenylenediamine and 320kg of DMF in the reaction kettle, add 58.7kg of BPDA after dissolving (adding in 3 times), react at room temperature for 8 hours, and obtain a polyamic acid resin with a viscosity of 200,000 centipoise solution, which is transported to a defoaming kettle for defoaming, to obtain a defoamed polyamic acid resin solution;

[0044] 3) Set the temperature of the drooling upper drying tunnel to 160°C and the temperature of the lower drying tunnel to 170°C, first coat the coating liquid on the steel strip, and then pour the defoamed polyamic acid resin solution onto the steel strip, Remove 69% solvent in the salivation furnace, obtain polyamic acid gel film; W...

Embodiment 3

[0050] Repeat Example 1, the difference is: in step 1), the amount of DMP-30 is changed to 10 parts.

[0051] The imidization rate and mechanical properties such as tensile strength and elongation at break of the polyamic acid gel film edge (that is, the part coated with the coating liquid) prepared in step 3) of the present embodiment are detected, and the result As shown in Table 1 below.

[0052] When the method described in this example is continuously produced for 10 days, the number of broken edges and the total number of broken films, yield and yield during longitudinal stretching, transverse stretching and imidization are counted respectively, and the results are shown in Table 1 below .

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com