Manufacturing method of polyimide/polyacrylonitrile-based blended preoxidized fiber

A technology for pre-oxidizing fibers and polyimide, applied in the field of fibers, can solve the problems of low thermal expansion coefficient of heat transfer, difficult preparation, hindering the development of pitch-based carbon fibers, etc., and achieves the effect of increasing the degree of pre-oxidation and improving the time-consuming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

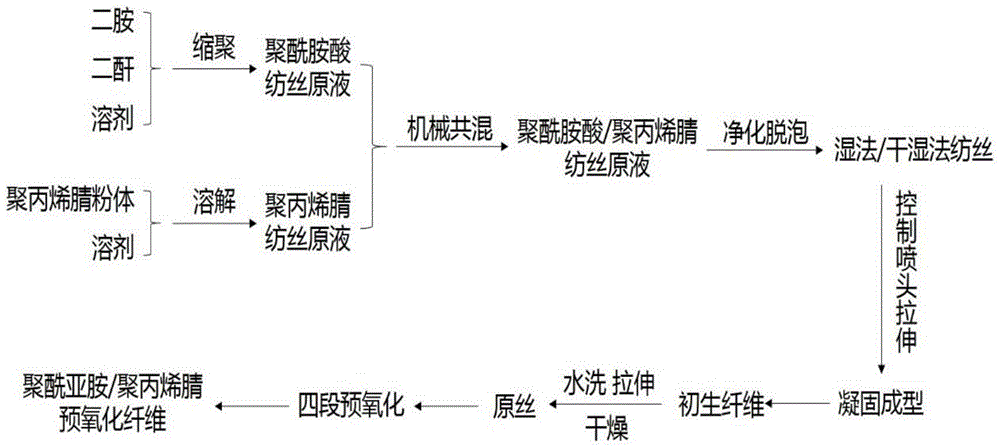

[0038] A: Synthesis of polyamic acid / polyacrylonitrile blended spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. N 2 Under protection conditions, dissolve the PAN powder in DMSO to prepare a PAN solution. N 2 Under protection conditions, a certain amount of PAN solution is added to the PAA system, and PAN accounts for 2% of the mass fraction of PAA (excluding solvent) components.

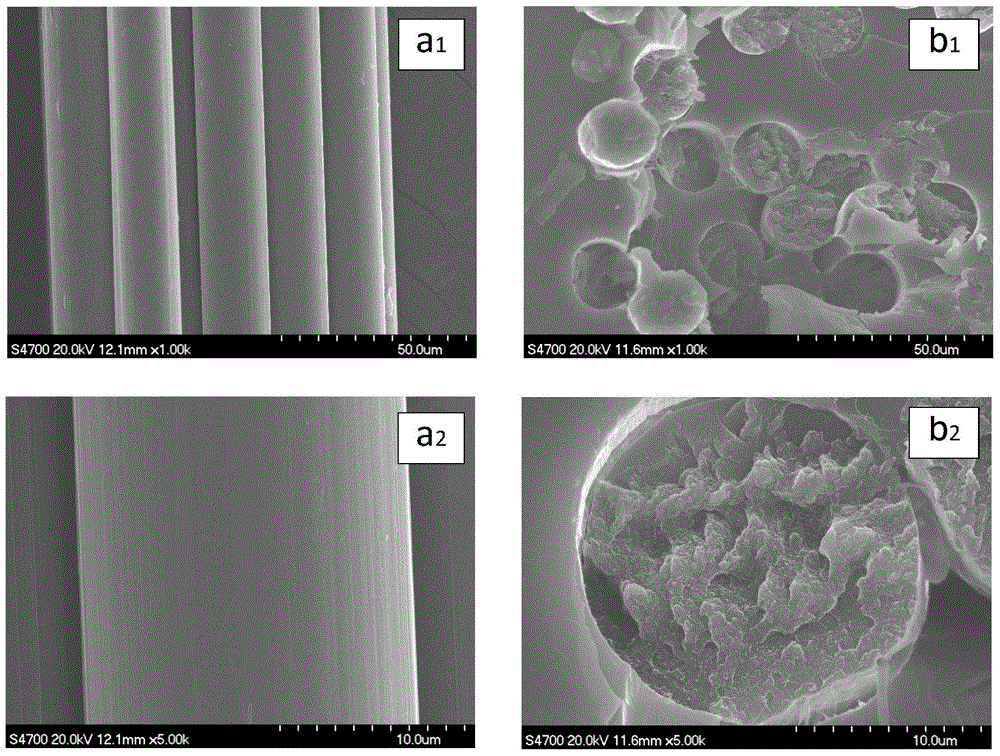

[0039] B: Preparation of polyamic acid / polyacrylonitrile blend nascent fiber. The blended spinning solution is defoamed, and the nascent fiber is prepared by the wet spinning process.

[0040] C: Preparation of polyamic acid / polyacrylonitrile blend precursor. The blended nascent fiber is subjected to a layered heating treatment, and passes through 60°C, 70°C, 80°C, and 110°C in sequence to complete dehydration and solvent removal.

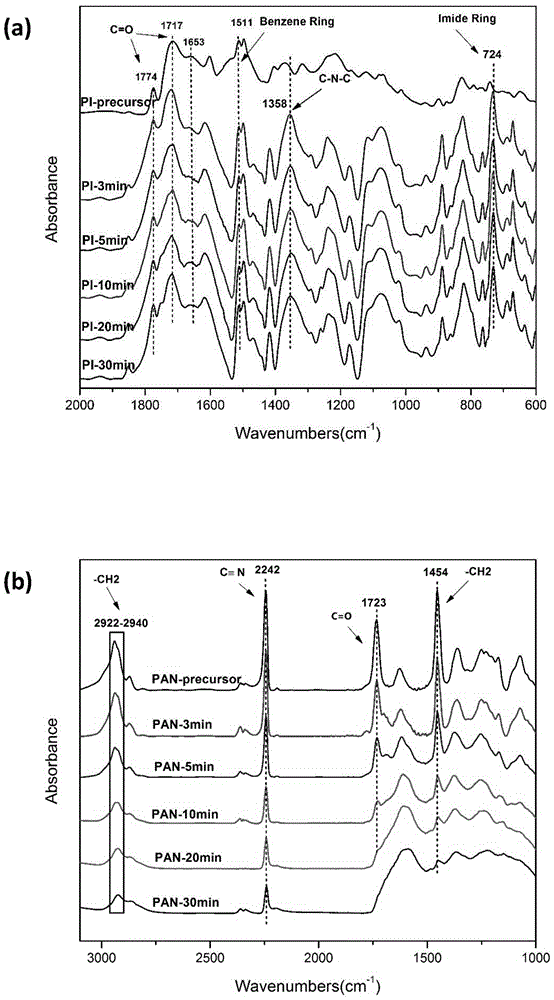

[0041] D: Preparation of polyimide / polyacryloni...

Embodiment 2

[0043] A: Synthesis of polyamic acid / polyacrylonitrile blended spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. N 2 Under protection conditions, dissolve the PAN powder in DMSO to prepare a PAN solution. N 2 Under protection conditions, a certain amount of PAN solution is added to the PAA system, and PAN accounts for 2% of the mass fraction of PAA (excluding solvent) components.

[0044] B: Preparation of polyamic acid / polyacrylonitrile blend nascent fiber. The blended spinning solution is defoamed, and the nascent fiber is prepared by the wet spinning process.

[0045] C: Preparation of polyamic acid / polyacrylonitrile blend precursor. The blended nascent fiber is subjected to a layered heating treatment, and passes through 60°C, 70°C, 80°C, and 110°C in sequence to complete dehydration and solvent removal.

[0046] D: Preparation of polyimide / polyacryloni...

Embodiment 3

[0048] A: Synthesis of polyamic acid / polyacrylonitrile blended spinning solution. BPDA, ODA and p-PDA are mechanically stirred in DMSO at low temperature for a certain period of time to prepare a polyamic acid solution of BPDA / ODA / p-PDA. The PAN powder is dissolved in DMSO to prepare a PAN solution. A certain amount of PAN solution is added to the PAA system, and PAN accounts for 10% of the mass fraction of PAA (excluding solvent) components.

[0049] B: Preparation of polyamic acid / polyacrylonitrile blend nascent fiber. The blended spinning solution is defoamed, and the nascent fiber is prepared by the wet spinning process.

[0050] C: Preparation of polyamic acid / polyacrylonitrile blend precursor. The blended nascent fiber is subjected to a layered heating treatment, and passes through 90°C, 100°C, 120°C, and 160°C in sequence to complete dehydration and solvent removal.

[0051] D: Preparation of polyimide / polyacrylonitrile blend pre-oxidized fiber. The blended raw yarn is su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com