A flow-type ultrasonic treatment method for intercrystalline acid in simple explosives

An elemental explosive and ultrasonic treatment technology, which is applied to explosives, explosives processing equipment, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc. problems, to achieve the effect of reducing water consumption, improving energy utilization, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

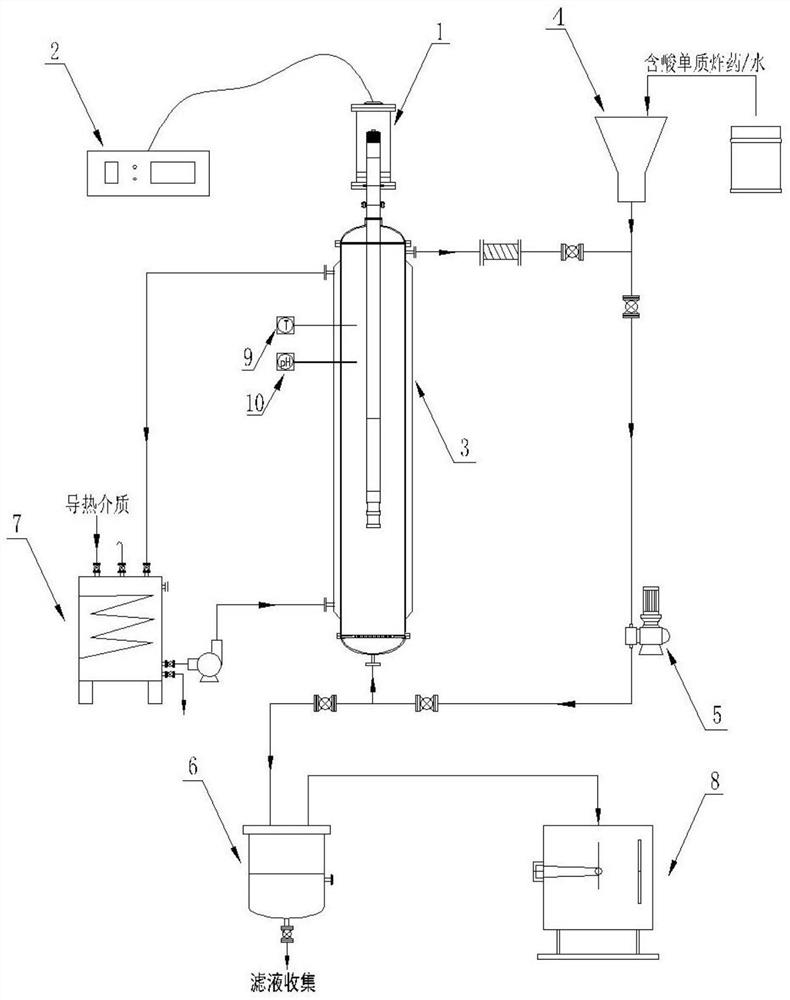

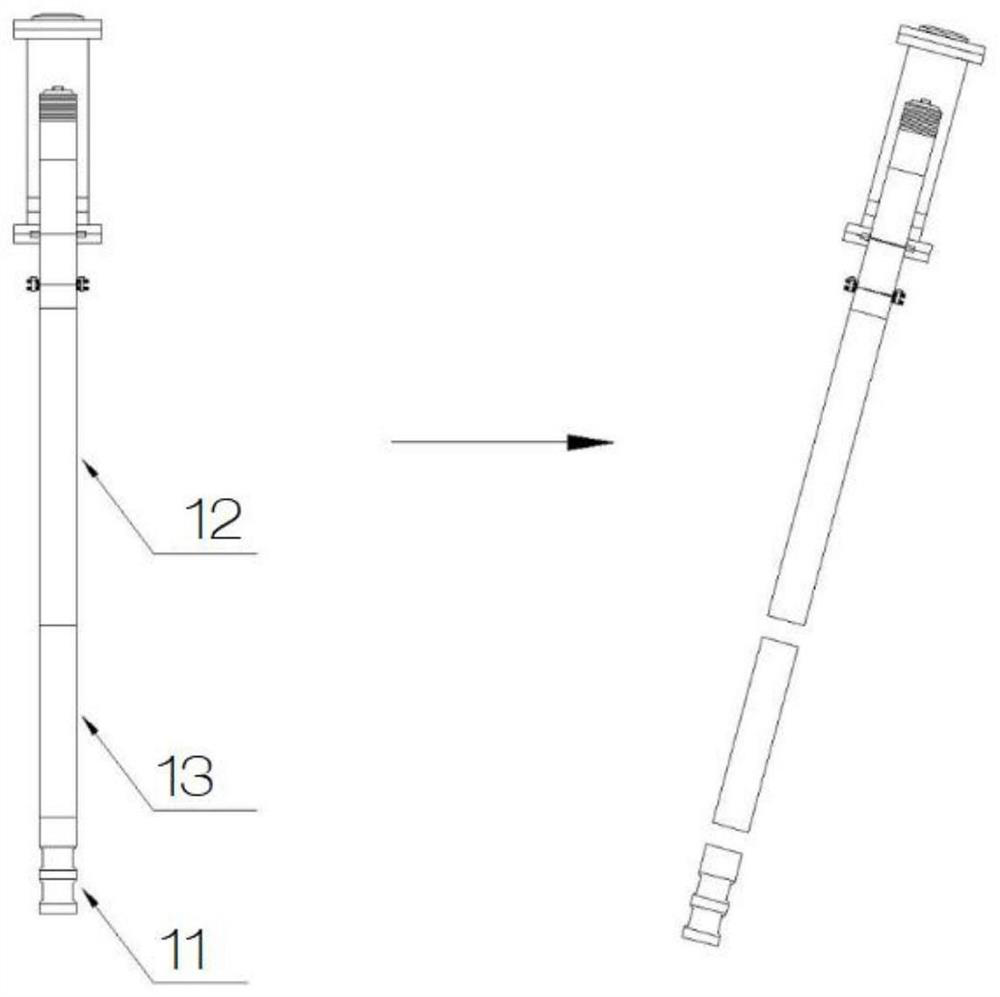

[0035] The present embodiment provides a method for flow-type ultrasonic treatment of simple explosive intercrystalline acid, which specifically includes the following steps:

[0036] S1. Take 1 kg of Oktokin crude product with an acidity of about 10%, measure 1.5L of tap water to prepare a mixed solution, and pass the mixed solution into the circulation pipeline through the stainless steel feeder 4;

[0037] S2. Turn on the heating refrigerator 7, heat the 2.5L scrubber 3 through the jacket, and maintain the temperature inside the scrubber at 45±1°C;

[0038] S3. Start the magnetic circulating pump 5, set the flow rate to 500L / h, the mixture of Octojin crude product and water enters from the lower end of the scrubber 3, and flows out from the overflow port at the upper end after the volume is full, and observe the liquid through the pipeline sight glass After flowing out, continue to circulate for 5 minutes;

[0039] S4, start the ultrasonic generator 1, set the ultrasonic p...

Embodiment 2

[0042] The present embodiment provides a method for flow-type ultrasonic treatment of simple explosive intercrystalline acid, which specifically includes the following steps:

[0043] S1. Take 2kg of Taian crude product with an acidity of about 4%, measure 2L of tap water to prepare a mixed solution, and pass the mixed solution into the circulation pipeline through the stainless steel feeder 4;

[0044] S2. Turn on the heating refrigerator 7, heat the 2.5L scrubber 3 through the jacket, and maintain the temperature in the scrubber at 35±1°C;

[0045]S3. Start the magnetic circulating pump 5, set the flow rate to 600L / h, the mixture of Octojin crude product and water enters from the lower end of the scrubber 3, and flows out from the overflow port at the upper end after the volume is full, and observe the liquid through the pipeline sight glass After flowing out, continue to circulate for 5 minutes;

[0046] S4, start the ultrasonic generator 1, set the ultrasonic power to 50%...

Embodiment 3

[0049] The present embodiment provides a method for flow-type ultrasonic treatment of simple explosive intercrystalline acid, which specifically includes the following steps:

[0050] S1. Take 10 kg of crude Hessogin with an acidity of about 11.5%, measure 20 L of tap water to prepare a mixed solution, and pass the mixed solution into the circulation pipeline through the stainless steel feeding machine 4;

[0051] S2. Turn on the heating refrigerator 7, heat the 30L scrubber 3 through the jacket, and maintain the temperature in the scrubber at 40±1°C;

[0052] S3. Start the magnetic circulation pump 5, set the flow rate to 1500L / h, the mixture of Octojin crude product and water enters from the lower end of the scrubber 3, and flows out from the overflow port at the upper end after the volume is full, and observe the liquid through the pipeline sight glass After flowing out, continue to circulate for 5 minutes;

[0053] S4, start the ultrasonic generator 1, set the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com