a2b7 type gadolinium-containing nickel hydrogen storage alloy, negative electrode, battery and preparation method

A technology of hydrogen storage alloy and negative electrode, which is applied in the field of negative electrode, battery and its preparation, and hydrogen storage alloy. It can solve the problems of poor self-discharge characteristics, improve self-discharge characteristics, increase cycle life, improve activation cycle times and high temperature The effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The hydrogen storage alloy of the present invention can be prepared by various methods. For example, including high-temperature melting and casting method, high-temperature melting-rapid quenching method, mechanical alloying method, powder sintering method, high-temperature melting-gas atomization method, reduction diffusion method, replacement diffusion method, combustion synthesis method, self-propagating high-temperature synthesis method and chemical method. Specifically, the method for preparing the hydrogen storage alloy of the present invention includes: (1) a step of forming an alloy sheet or an alloy block; (2) a heat treatment step. The metal raw material is smelted, then flaked to form alloy flakes or cast into alloy blocks, and then heat treated to obtain A 2 B 7 gadolinium-containing nickel hydrogen storage alloy.

[0093] In step (1), the overall composition satisfies RE x Gd y Ni z-a-b mn a al b Under the protection of inert gas, the metal raw mate...

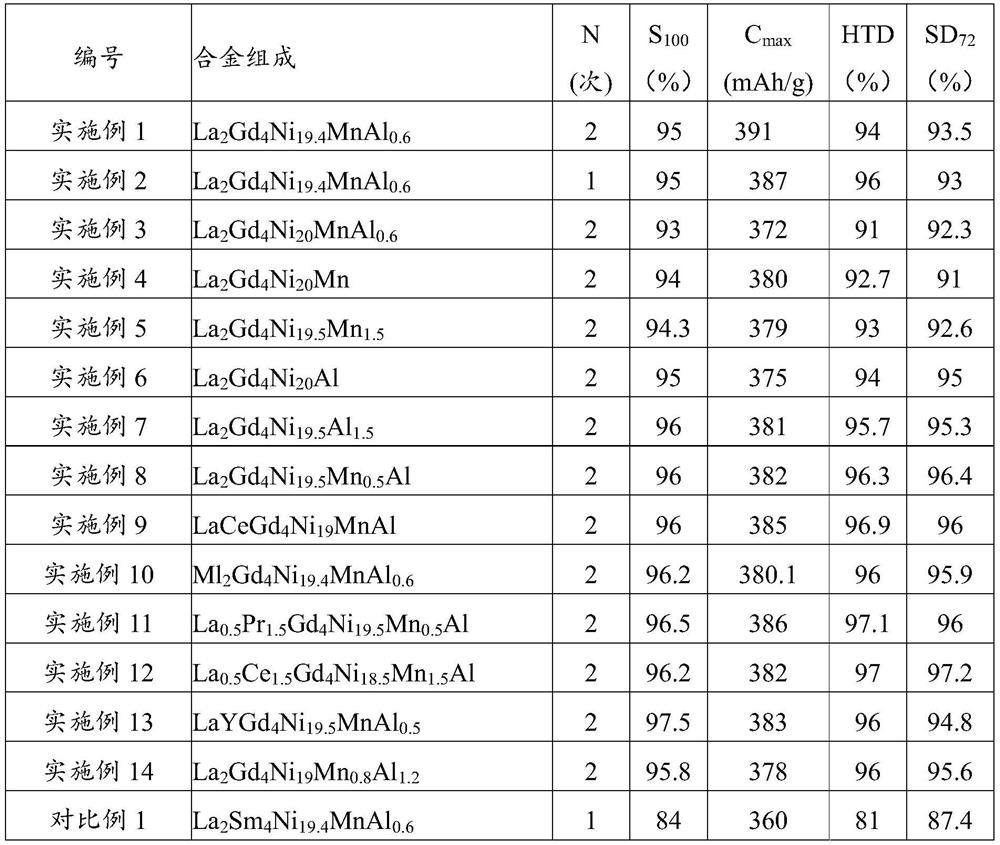

Embodiment 1

[0107] According to the formula in Table 1, the metal raw materials Ni, Mn, Al, La, and Gd were placed in the vacuum melting furnace from the bottom to the top in sequence, and then the vacuum melting furnace was purged with argon for 5 times, and then Vacuumize the vacuum melting furnace to an absolute vacuum of ≤5Pa, and fill it with argon to a relative vacuum of -0.055MPa. The vacuum melting furnace is heated to 1300°C, and the heating is stopped after the metal raw materials in the furnace are completely melted into a metal solution. Cast the molten metal to a cooling copper roll, and flake it into an alloy sheet with a thickness of 0.2 mm. The alloy sheet was placed in an environment with an absolute vacuum of 0.01 Pa and protected by argon, and heat-treated at 875° C. for 16 hours to obtain a gadolinium-containing nickel hydrogen storage alloy.

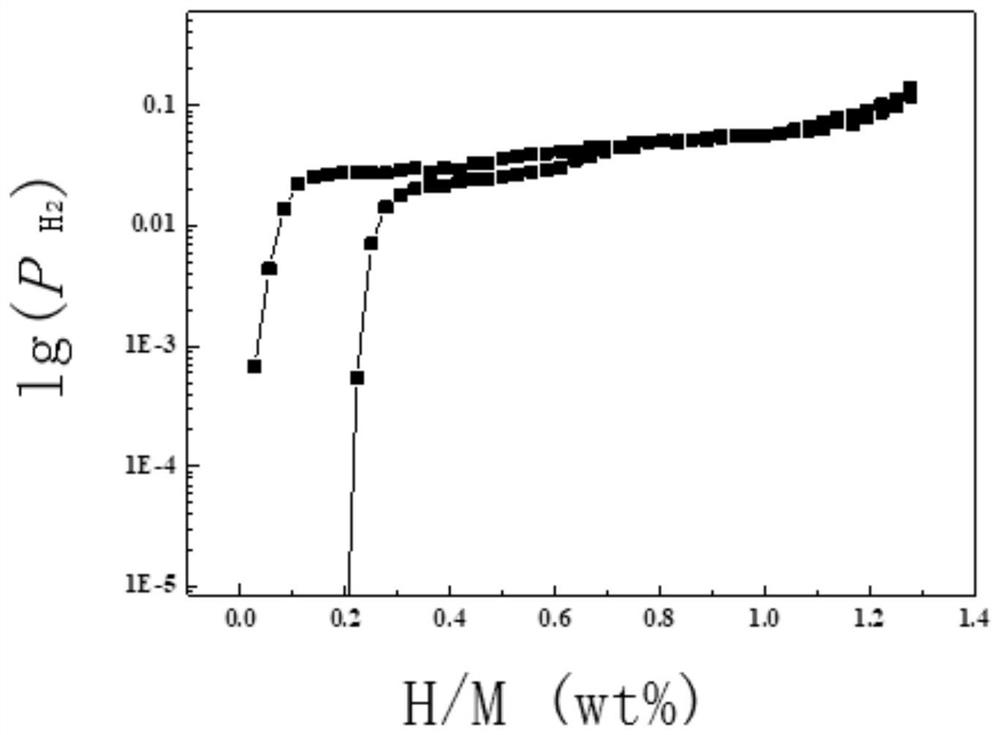

[0108] The pressure-composition-isothermal (P-C-T) curve of gained gadolinium-containing nickel hydrogen storage alloy sees ...

Embodiment 2

[0110] According to the formula in Table 1, the metal raw materials Ni, Mn, Al, La, and Gd are placed in the vacuum melting furnace from the bottom to the top in sequence, and then the vacuum melting furnace is purged with argon for 5 times, and then Vacuumize the vacuum melting furnace to an absolute vacuum of ≤5Pa, and fill it with argon to a relative vacuum of -0.055MPa. The vacuum melting furnace is heated to 1300°C, and the heating is stopped after the metal raw materials in the furnace are completely melted into a metal solution. Cast the molten metal to a cooling copper roll, and flake it into an alloy sheet with a thickness of 0.2 mm. The alloy sheet was placed in an environment with an absolute vacuum of 0.01 Pa and protected by argon, and heat-treated at 950° C. for 16 hours to obtain a gadolinium-containing nickel hydrogen storage alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com