A system for removing dioxin from garbage fly ash and its treatment method

A technology for waste fly ash removal, applied in combustion methods, combustion product treatment, emission prevention, etc. problem, to achieve the effect of no power drive, compact structure and reasonable arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

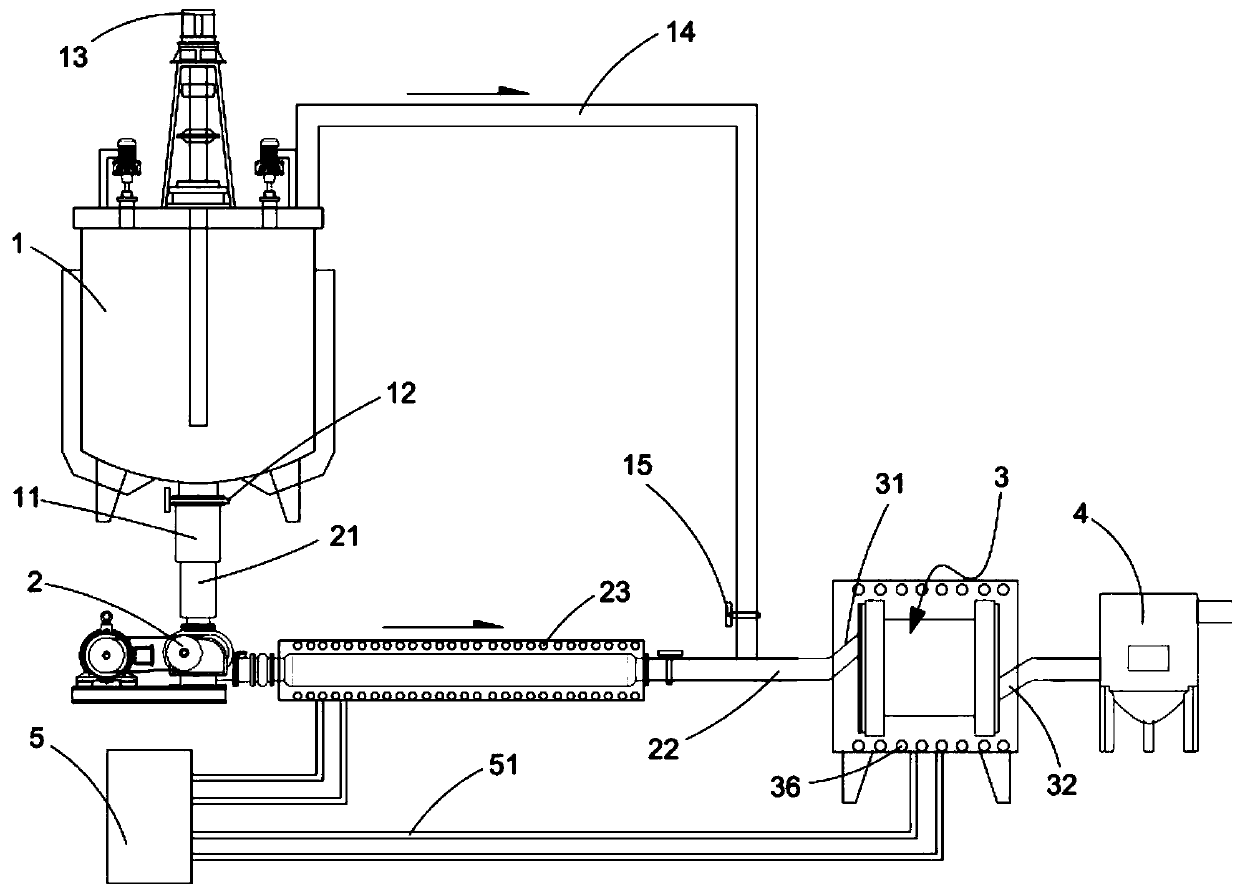

[0063] Reference attached figure 1 A dioxin removal system for garbage fly ash according to Embodiment 1 of the present invention is described.

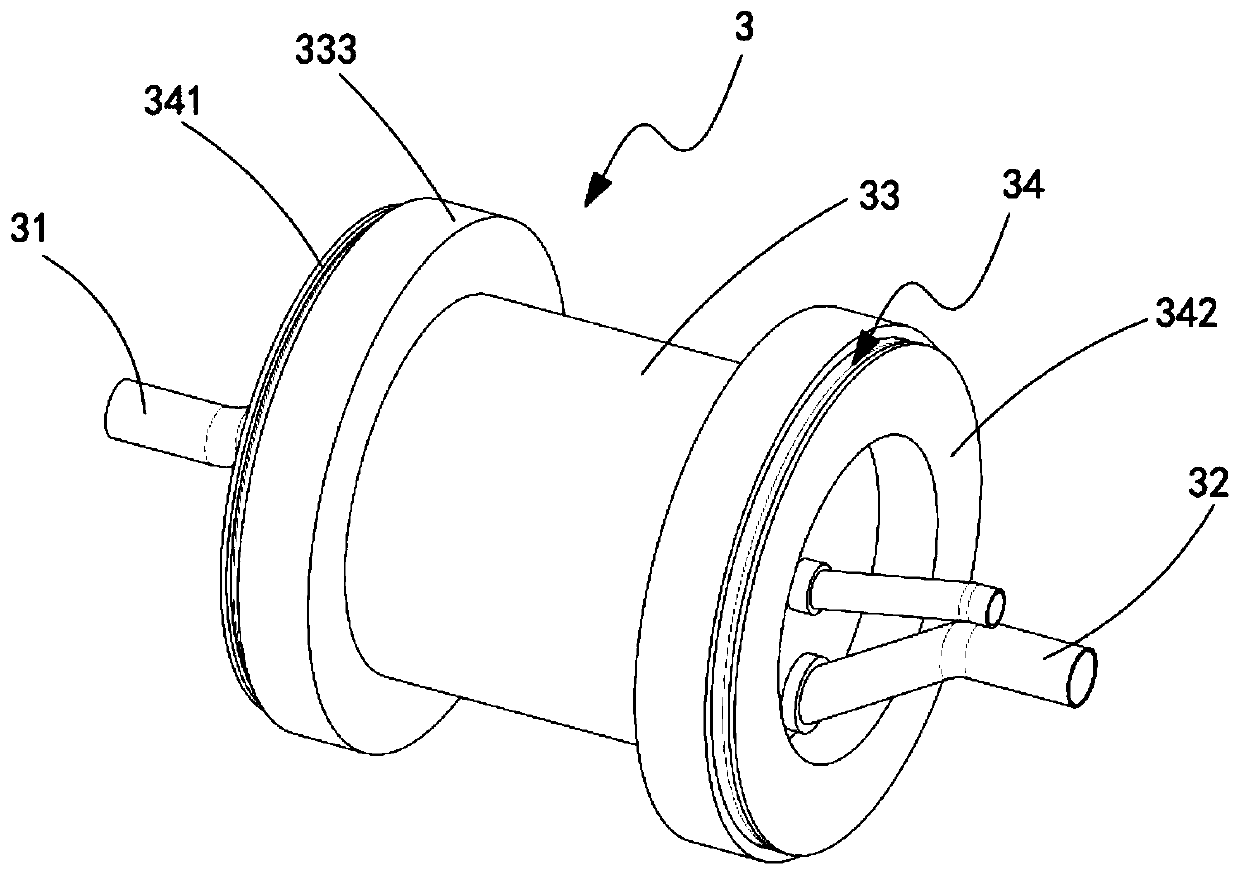

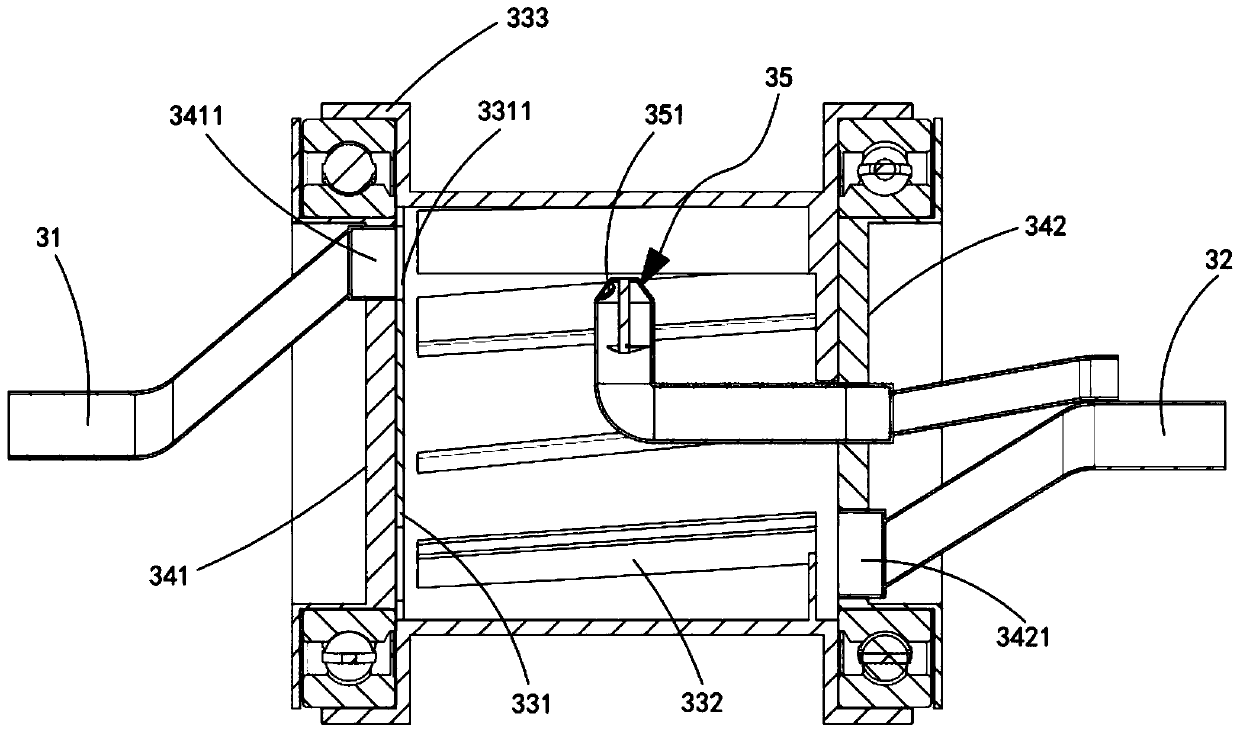

[0064] Such as Figure 1 to Figure 3 As shown, a garbage fly ash dioxin removal system is characterized in that it includes a pyrolysis furnace 1, a positive pressure pneumatic conveyor 2, a dioxin removal device 3, a bag filter 4 and a water cooling device 5. The feed port a21 of the positive pressure pneumatic conveyor 2 is connected with the discharge port b11 of the pyrolysis furnace 1, and its discharge port a22 is connected with the feed port c31 of the dioxin removal device 3. The dioxin The discharge port c32 of the dioxin removal device 3 is communicated with the bag filter 4, and the water cooling device 5 is connected with the positive pressure pneumatic conveyor 2 and the dioxin removal device 3 respectively through a water pipe 61; The dioxin removal device 3 includes:

[0065] Housing 33, the feeding end of the housi...

Embodiment 2

[0098] Reference attached figure 1 A treatment method for removing dioxins from garbage fly ash according to the second embodiment of the present invention is described.

[0099] A treatment method for removing dioxin from garbage fly ash, characterized in that it comprises the following steps:

[0100] Step 1. Material high temperature pyrolysis gasification incineration

[0101] The waste material is pyrolyzed and burned in the pyrolysis furnace 1, the tail gas produced by the pyrolysis combustion is discharged into the pyrolysis tail gas pipe 14, and the dry ash produced after the pyrolysis is completed falls to the positive pressure pneumatic conveyor 2 through the discharge port b11;

[0102] Step 2. Purification treatment of high temperature exhaust gas

[0103] The tail gas produced by pyrolysis and combustion enters the dioxin removal device 3 for harmful substance adsorption to remove heavy metals and residual harmful substance dioxins in the tail gas, and at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com