Functional film and preparation method thereof, and flexible pressure sensor and preparation method thereof

A pressure sensor and film technology, applied in the field of sensors, can solve the problems of poor sealing of flexible pressure sensors, discount of contact electrification effect, high equipment dependence, etc., and achieve the effect of large change amount, high dielectric constant and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

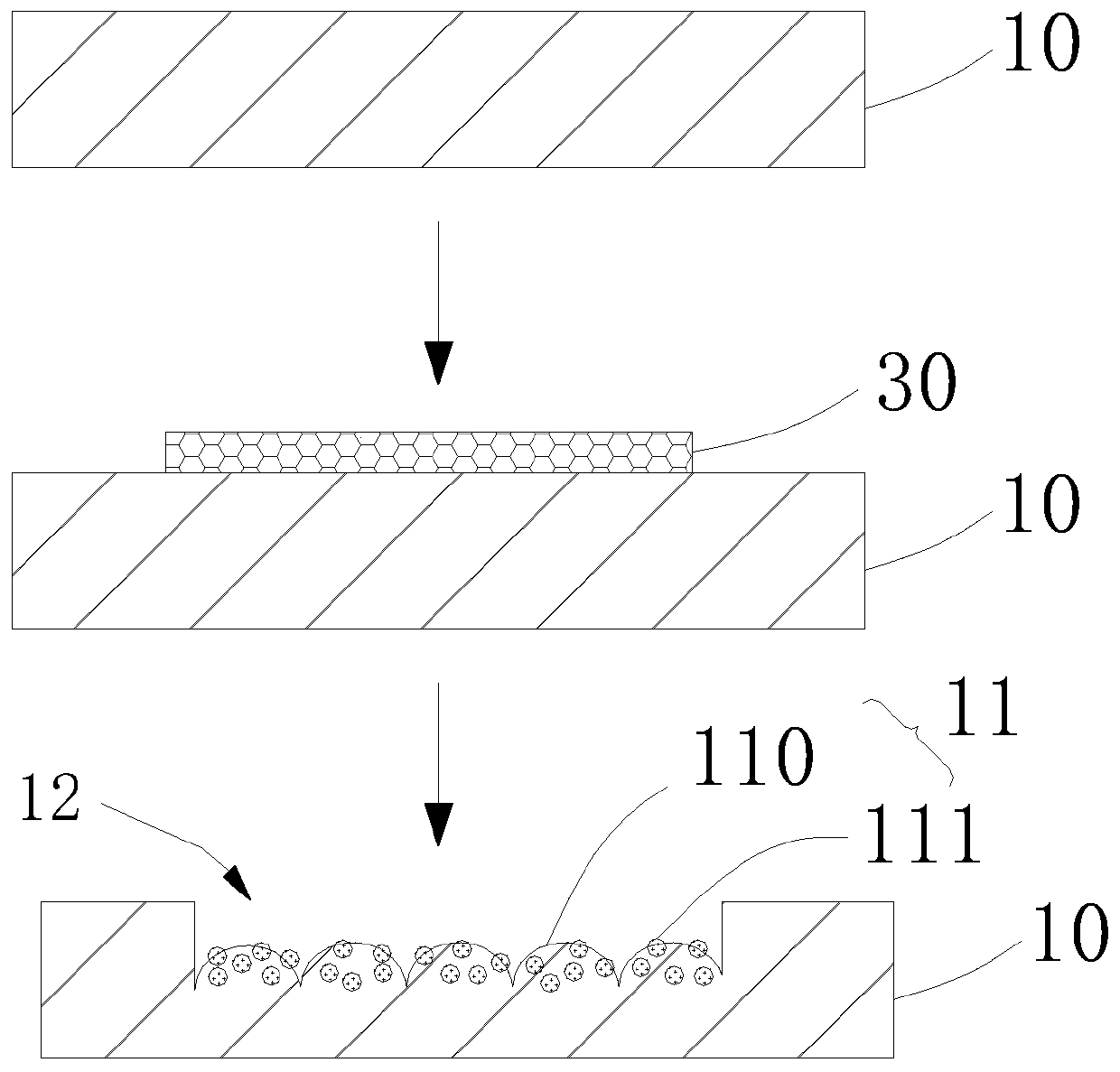

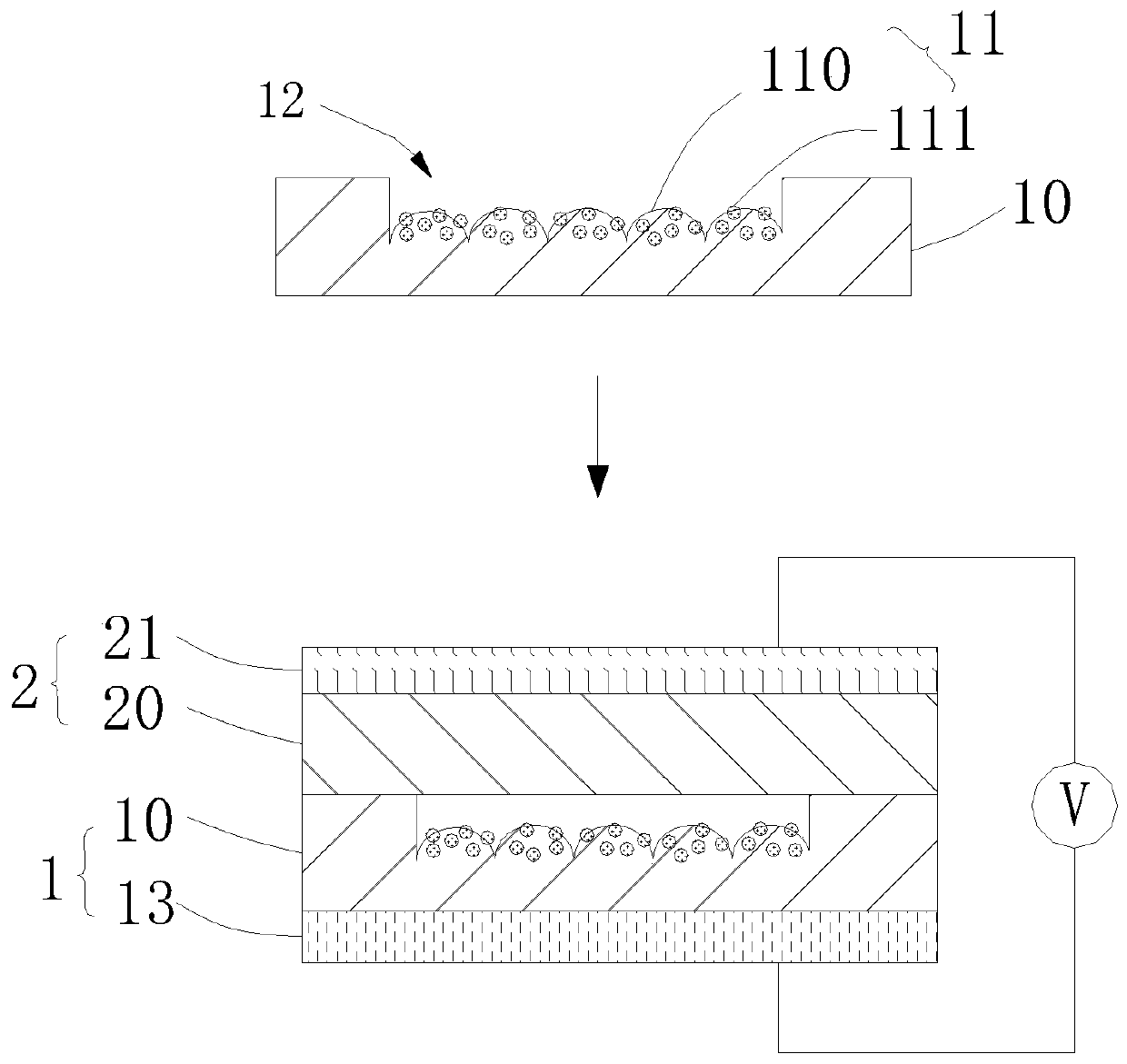

[0035] Such as figure 1 Shown, the preparation method of the functional thin film provided by the invention comprises:

[0036] (1) providing the first flexible thin film 10 and the suspension containing ferroelectric material precursor;

[0037] (2) forming the suspension on a surface of the first flexible film 10 to form a precursor layer 30 on the surface;

[0038] (3) Laser is used to irradiate the surface of the first flexible film 10 with the precursor layer 30, so that the surface of the first flexible film 10 forms a graphene microstructure 110, and the ferroelectric material precursor The body is transformed into ferroelectric material particles 111 and embedded in the interior and / or surface of the graphene microstructure 110 to form a composite microstructure 11 to obtain a functional film, wherein the surface of the composite microstructure 11 is lower than the first A groove 12 extending from the surface of the first flexible film 10 to the composite microstruct...

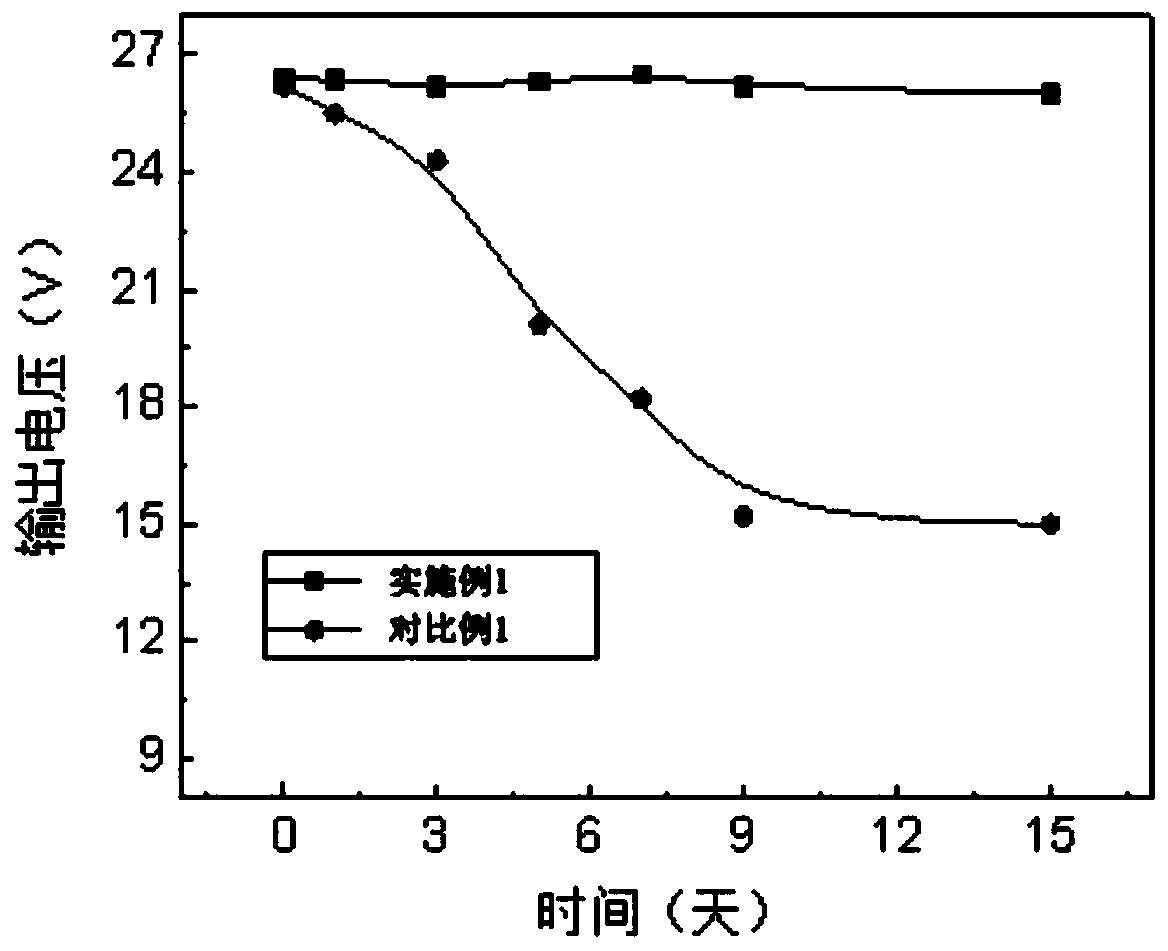

Embodiment 1

[0085] Dissolve butyl titanate and glacial acetic acid in isopropanol (the molar ratio of butyl titanate, isopropanol and glacial acetic acid is 1:6:3), and stir evenly to obtain mixed solution A. Weigh an equimolar amount of barium acetate, dissolve it in distilled water, stir to dissolve it completely, and obtain solution B. The solution B was mixed with the mixed solution A, stirred evenly and left to stand for 10 hours, then vacuum-dried at 150° C. for 5 hours to obtain a preform, which was washed with ethanol three times to obtain a barium titanate precursor. The barium titanate precursor was dispersed with isopropanol to obtain a barium titanate precursor suspension with a concentration of 10%.

[0086] Select the material as the first flexible film of PDMS, adopt O 2 Plasma treatment for 1 min to generate -OH, -COOH and other functional groups on the surface. Then, the above-mentioned barium titanate precursor suspension was spin-coated on the surface, and then dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com