Structure for realizing ultra-high temperature heating of synchrotron radiation light source in-situ tensile CT imaging experiment

A technique of in-situ stretching and CT imaging, applied in ohmic resistance heating, material analysis using wave/particle radiation, and testing material strength by applying stable tension/pressure, which can solve problems such as inability to heat ultra-high temperature samples , to avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

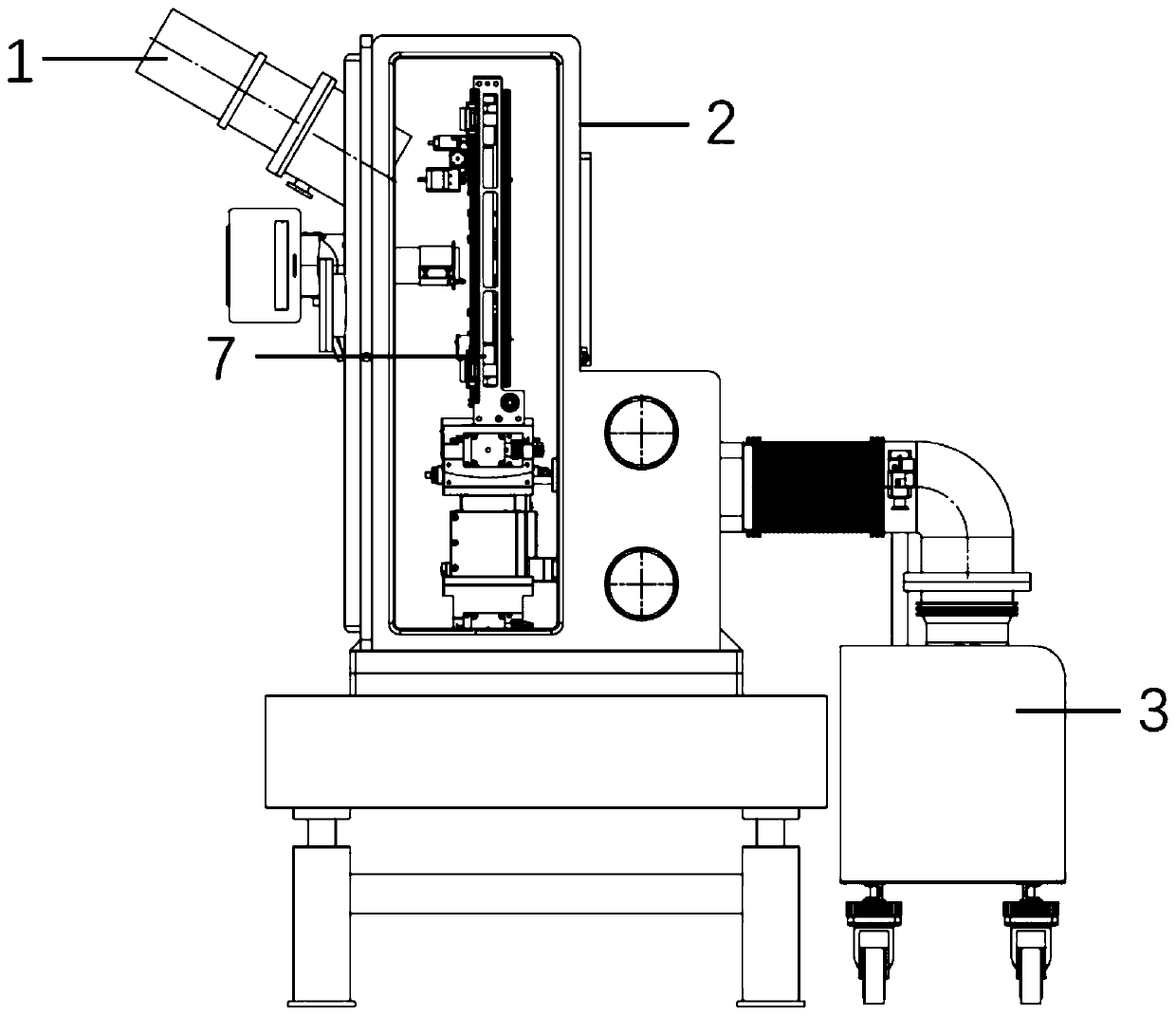

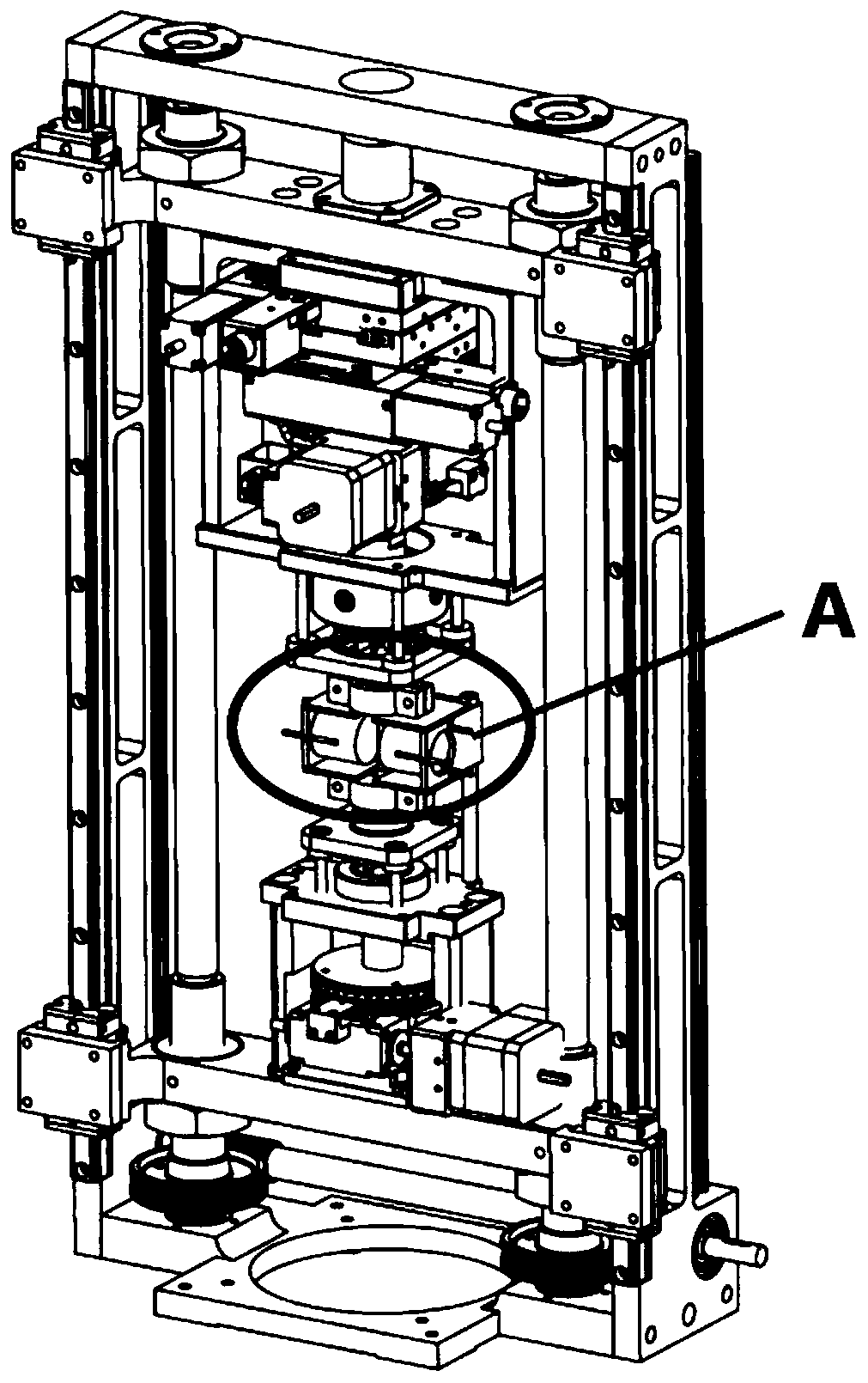

[0033] This embodiment discloses a structure for realizing ultra-high temperature heating in synchrotron radiation light source in situ stretching CT imaging experiments. The structure is as follows Figure 1-7 As shown, it includes an electron gun 1, a vacuum chamber 2, and a vacuum unit 3 connected to the vacuum chamber 2. The vacuum chamber 2 is provided with an in-situ stretching table 7. The structure of the in-situ stretching table is shown in Chinese patent 201810602634.2.

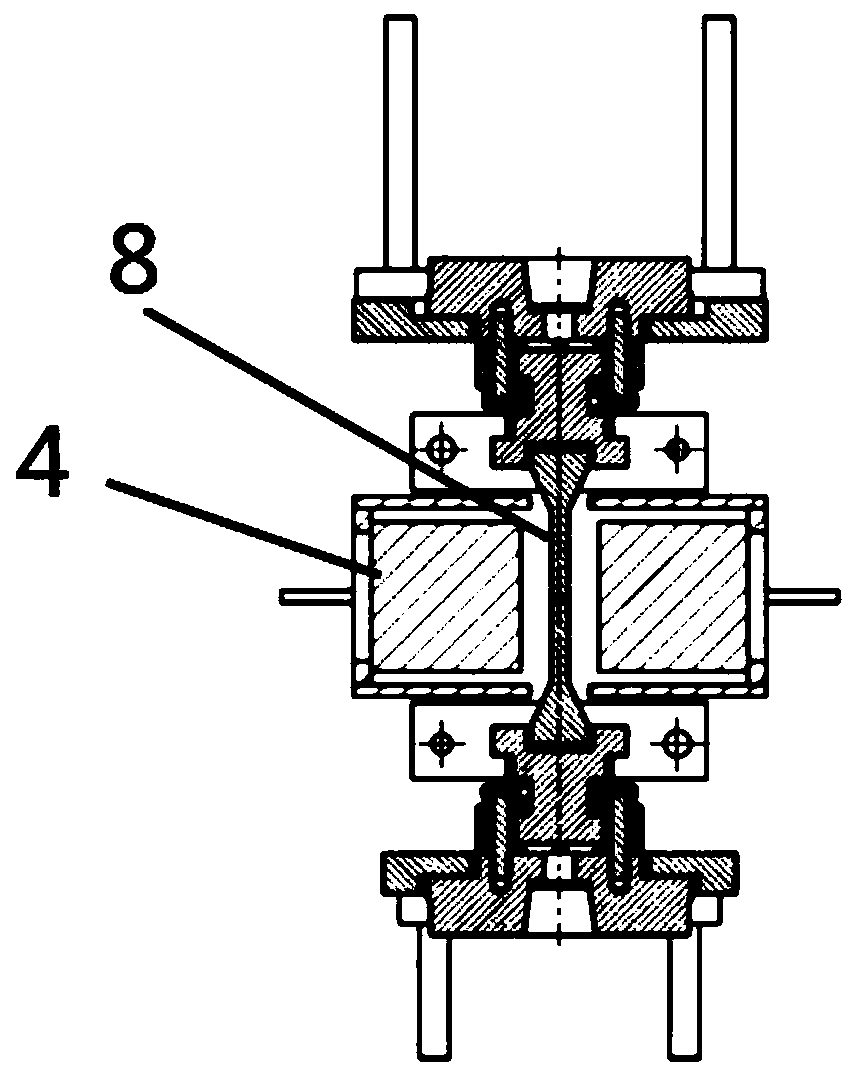

[0034] The electron gun 1 is arranged above the side wall of the vacuum chamber 2 and communicates with it, and the electron beam emitted by the electron gun can bombard the sample 8 on the in-situ stretching table; A heater 4 is arranged on the side, and a heat insulation structure is arranged between the rotating shaft of the in-situ stretching table 7 and the clamp; the rotating shaft of the in-situ stretching table 7 is covered with a cooling device.

[0035] The vacuum unit 3 communicates with ...

Embodiment 2

[0045] This embodiment discloses a synchrotron radiation in-situ stretching test bench, which includes the ultra-high temperature heating structure for realizing the in-situ stretching CT imaging experiment of a synchrotron radiation light source as described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com