Automatic calibration method for one-dimensional automobile thermal management model

A calibration method and thermal management technology, applied in the field of automatic calibration of one-dimensional automotive thermal management models, can solve the problems of poor adaptability, time-consuming manual calibration work, high error rate, etc., to reduce the burden, shorten the working cycle, and improve the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

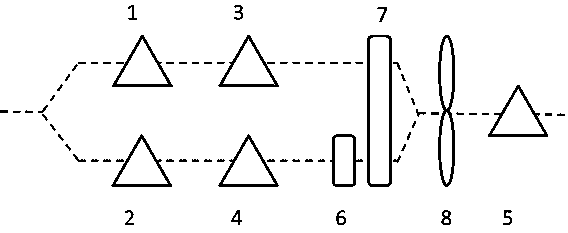

[0060] Example 1 (eg figure 2 shown)

[0061] Build the equivalent model of the air flow of the front-end module, where 1 and 2 represent the pressure increase coefficients of the front end of the upper and lower grilles respectively, 3, 4 and 5 represent the resistance coefficients of the upper and lower grilles and the engine compartment respectively, 6 and 7 are radiators, and 8 is the fan. The calibration requirement is to make the air volume of each radiator consistent with the test results at all vehicle speeds by adjusting the pressure increase coefficients and drag coefficients.

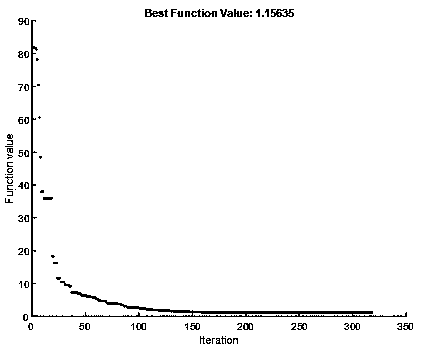

[0062] During calibration, the calibration parameters are the coefficients of 1~5 in the model, the initial value is 1, the constraint conditions are all greater than or equal to 0, the boundary parameter is the front wind speed, the calibration target is the air volume of the two radiators of 6 and 7, and the calibration value is For the air flow measurement results of the wind tunnel tes...

Embodiment 2

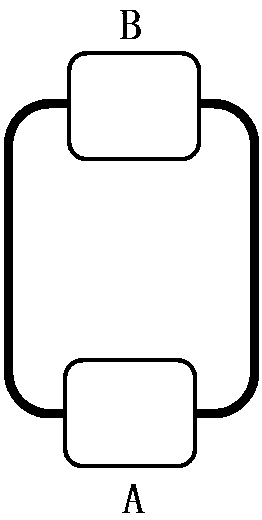

[0064] Example 2 (eg Figure 4 shown)

[0065] Build the equivalent model of passenger compartment heating, where A represents the engine and B represents the heater core. The calibration requirement is to fit the relevant thermal property parameters of the engine through two sets of test water temperatures with different boundaries. Two sets of trial boundaries are stored in the model in a table format, switched by trial number.

[0066] During calibration, the calibration parameters are the heat coefficient, heat capacity, convective heat transfer coefficient with the coolant, and convective heat transfer coefficient with the environment of the engine A. The constraint conditions are all greater than 0, the boundary parameters are the simulation time, the test number, and the calibration target is heating The water temperature at the inlet of core body B, the calibration value is two Excel file names, which store the inlet water temperature results of the two tests respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com