Preparation method of super-hydrophobic sponge material for oil-water separation

A super-hydrophobic sponge and oil-water separation technology, applied in the field of oil-water separation materials, can solve the problems of weak oil absorption and water resistance, affecting oil absorption efficiency and separation effect, and achieve the best adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

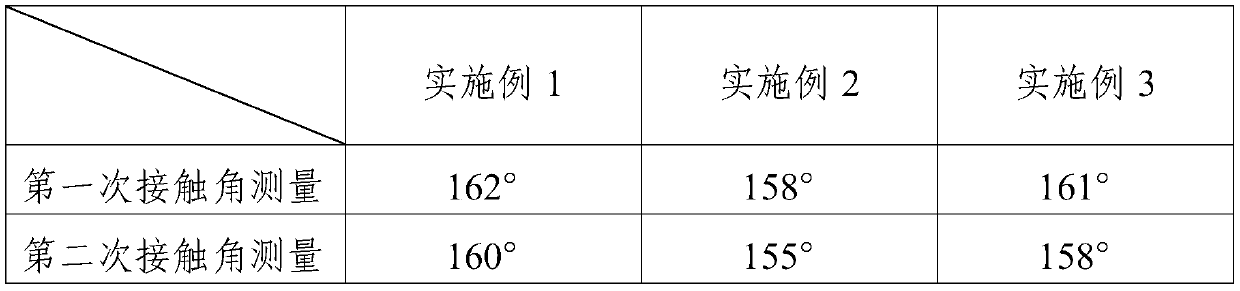

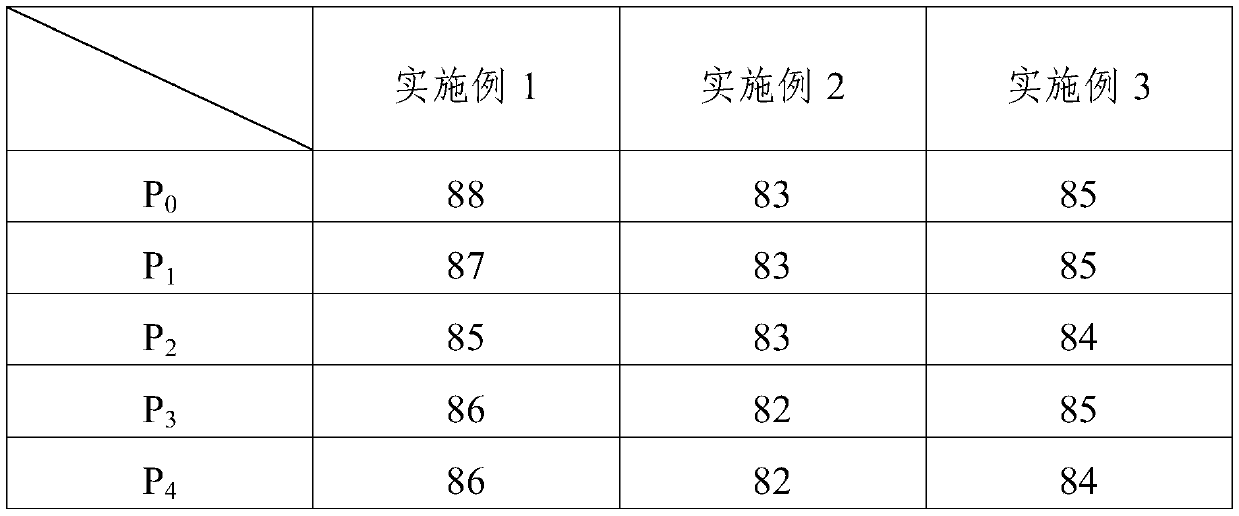

Embodiment 1

[0032] A preparation method of superhydrophobic sponge material for oil-water separation:

[0033] Add polyether silicone, polyoxypropylene glycol, and toluene into the reactor, the mass ratio of polyether silicone and polyoxypropylene glycol is 1:8, stir and mix evenly, heat up to 45°C, and then Add isophorone diisocyanate and dibutyltin laurate, continue to react for 8 hours, add γ-aminopropyltrimethoxysilane and stir rapidly for 3 minutes, pour the mixture into the mold, and place the mold in an oven at 1°C / min Raise the temperature to 70°C for 30 minutes and then raise the temperature to 110°C for 8 hours at a rate of 6°C / min. , concentrated sulfuric acid, and water at a mass ratio of 1:1:20, heat the coarsening solution in a water bath at 40°C, then immerse the semi-finished product A for 1 minute, take it out, wash it with a large amount of water until it is neutral, and then use the freeze-drying method at a low temperature of -60°C Next, dry it to obtain the semi-fini...

Embodiment 2

[0037] A preparation method of superhydrophobic sponge material for oil-water separation:

[0038]Add polyether silicone, polyoxypropylene glycol, and toluene into the reactor, the mass ratio of polyether silicone and polyoxypropylene glycol is 1:8, stir and mix evenly, heat up to 50°C, and then Add isophorone diisocyanate and dibutyltin laurate, continue to react for 6 hours, add γ-aminopropyltrimethoxysilane and stir quickly for 2 minutes, pour the mixture into the mold, and place the mold in an oven at 1°C / min Raise the temperature to 60°C for 40 minutes and then raise the temperature to 110°C for 5 hours at a rate of 8°C / min to form. After cooling to room temperature, a semi-finished product A is obtained. Dissolve chromium oxide and concentrated sulfuric acid in water to make a coarsening solution. Chromium oxide , concentrated sulfuric acid, and water at a mass ratio of 1:1:20, heat the coarsening solution in a water bath at 40°C, then immerse the semi-finished product A...

Embodiment 3

[0042] A preparation method of superhydrophobic sponge material for oil-water separation:

[0043] Add polyether silicone, polyoxypropylene glycol, and toluene into the reactor, the mass ratio of polyether silicone and polyoxypropylene glycol is 1:8, stir and mix evenly, heat up to 55°C, and then Add isophorone diisocyanate and dibutyltin laurate, continue to react for 10 hours, add γ-aminopropyltrimethoxysilane and stir quickly for 2 minutes, pour the mixture into the mold, and place the mold in an oven at 3°C / min Raise the temperature to 60°C for 30 minutes at a rate of 5°C / min and then raise the temperature to 110°C for 5 hours at a rate of 5°C / min to form a semi-finished product A after cooling to room temperature. Dissolve chromium oxide and concentrated sulfuric acid in water to make a coarsening solution. , concentrated sulfuric acid, and water at a mass ratio of 1:1:20, heat the coarsening solution in a water bath at 40°C, then immerse the semi-finished product A for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com