Automatic unpacking and feeding equipment in production of non-sterile active pharmaceutical ingredients

A kind of raw material medicine, non-sterile technology, applied in the direction of packaging, transportation and packaging, loading/unloading, etc., can solve the problems of increasing the probability of contact between the operator and the drug, increasing the contamination of the drug, and low work efficiency, so as to achieve failure The effect of low probability, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

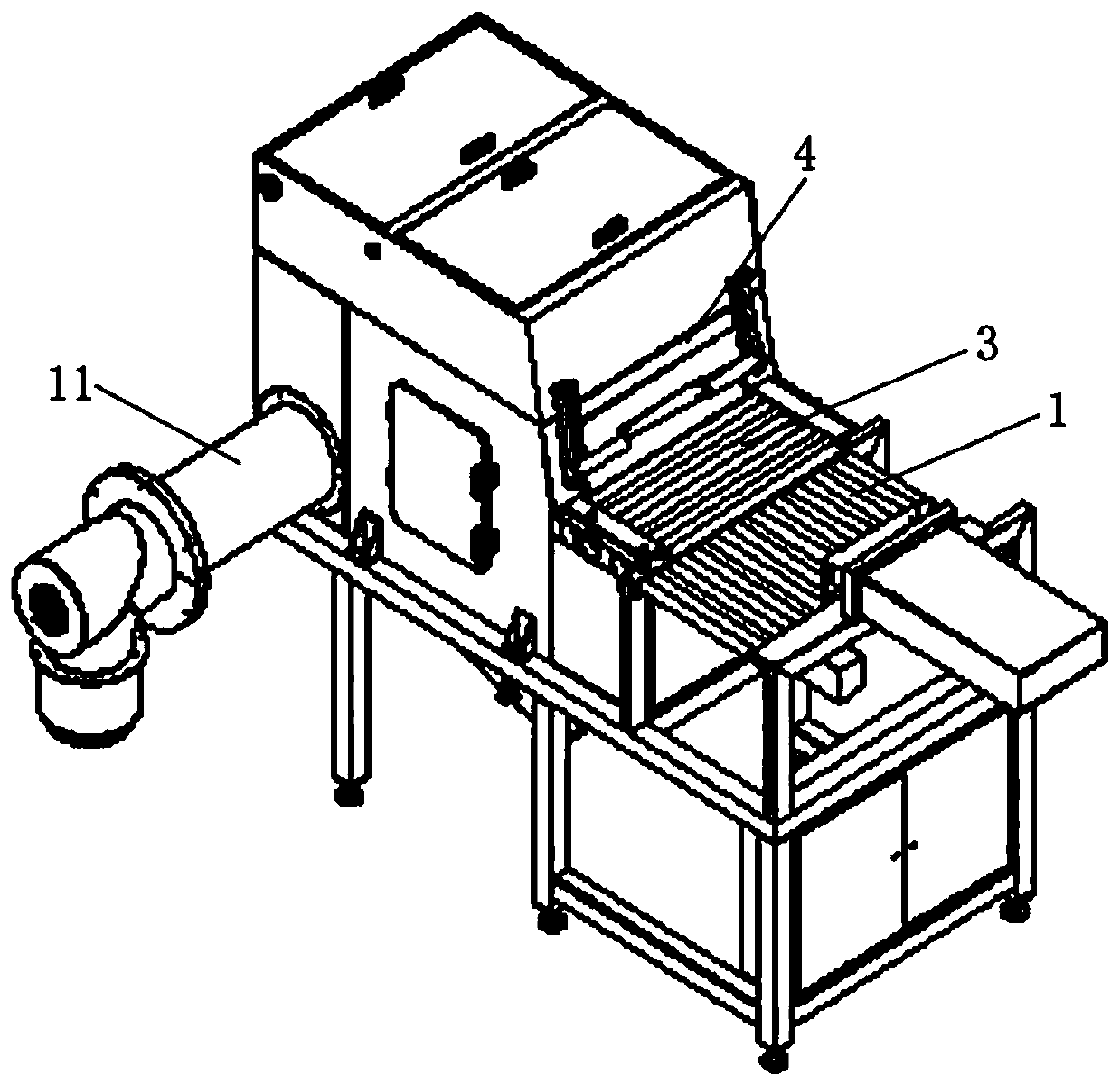

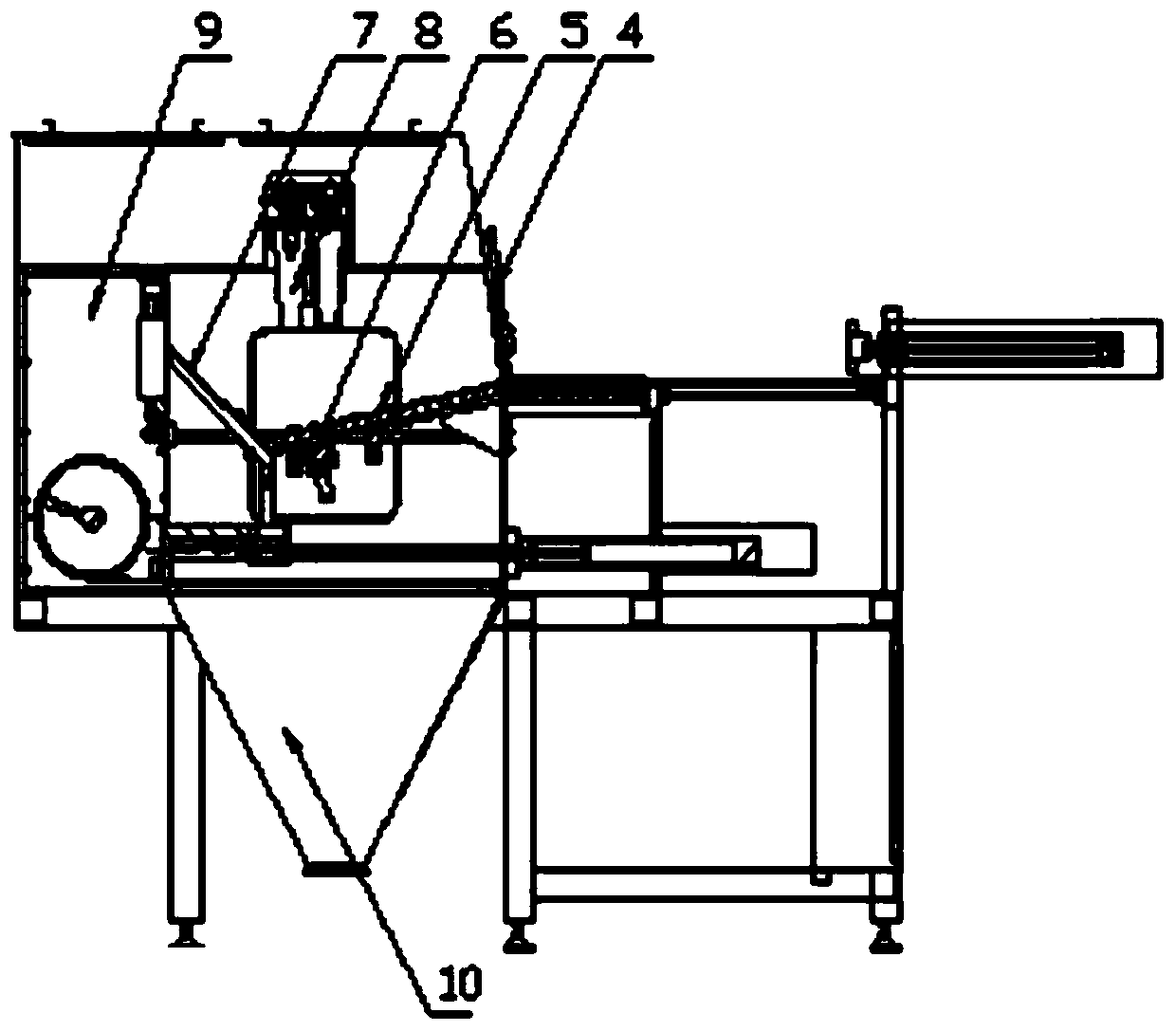

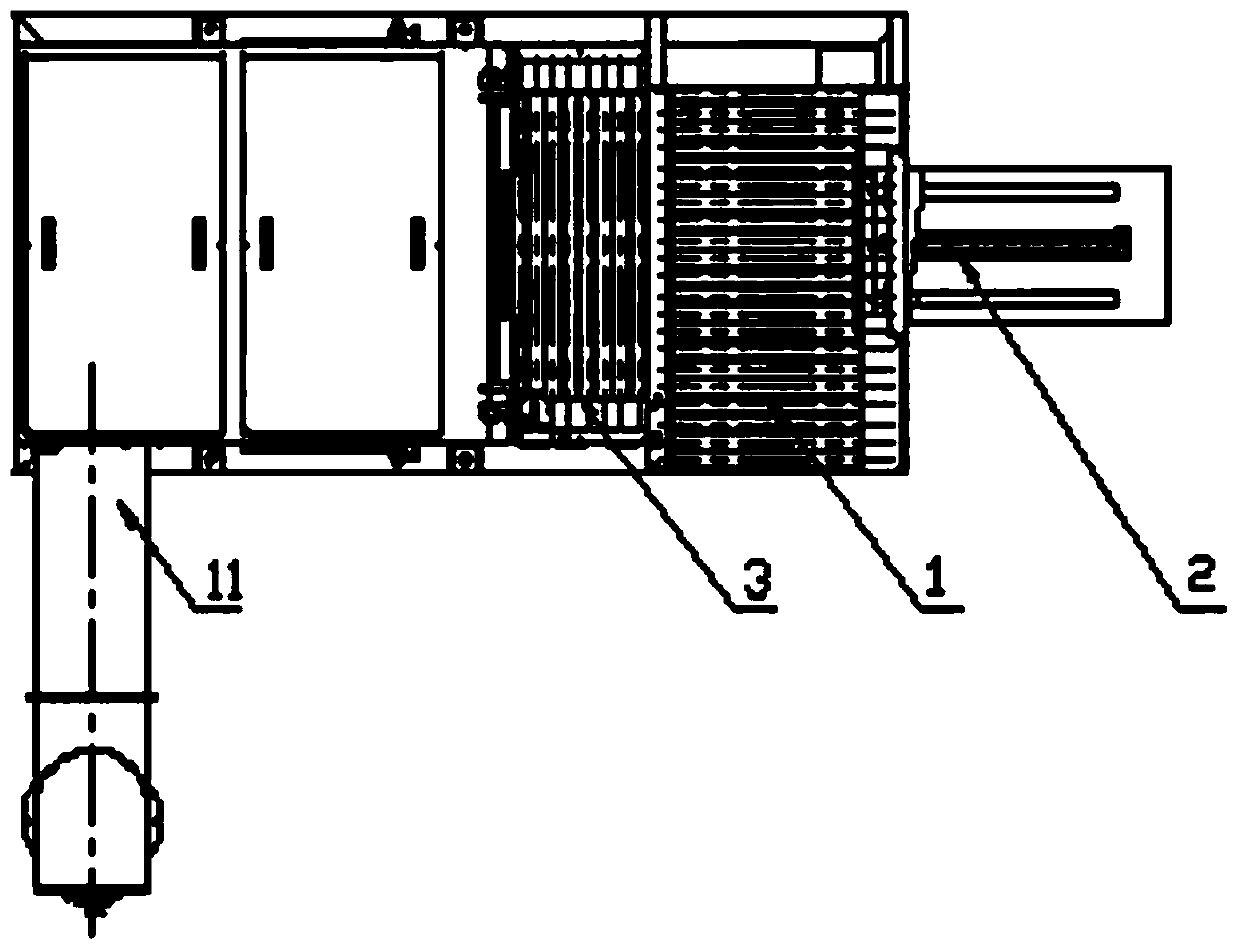

[0033] The automatic unpacking and feeding equipment in the production of non-sterile raw materials includes: a material entering unit, a feeding bin, a packaging removal and feeding unit, a packaging collection unit, a dust removal and filtering unit, and a control unit. The control unit is respectively connected with the material entering unit, The feeding bin body, packaging removal feeding unit, packaging collection unit, and dust removal and filtering unit are fixedly connected to control the coordinated operation of each unit. The delivered materials are sent into the feeding bin body through the material entering unit, and the outer packaging is removed through the packaging and feeding unit in the feeding bin body, and the outer packaging is collected by the packaging collection unit, and the feeding bin body is also provided with a dust removal filter unit , used to filter dust. Specifically as follows:

[0034] like Figure 1 to Figure 3 As shown, the automatic unp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com