A detection tool for processing ferrite soft magnetic core products

A technology for detecting tooling and soft magnetic cores, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of poor timeliness, labor-intensive, unable to meet the needs of use, and achieve strong applicability and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

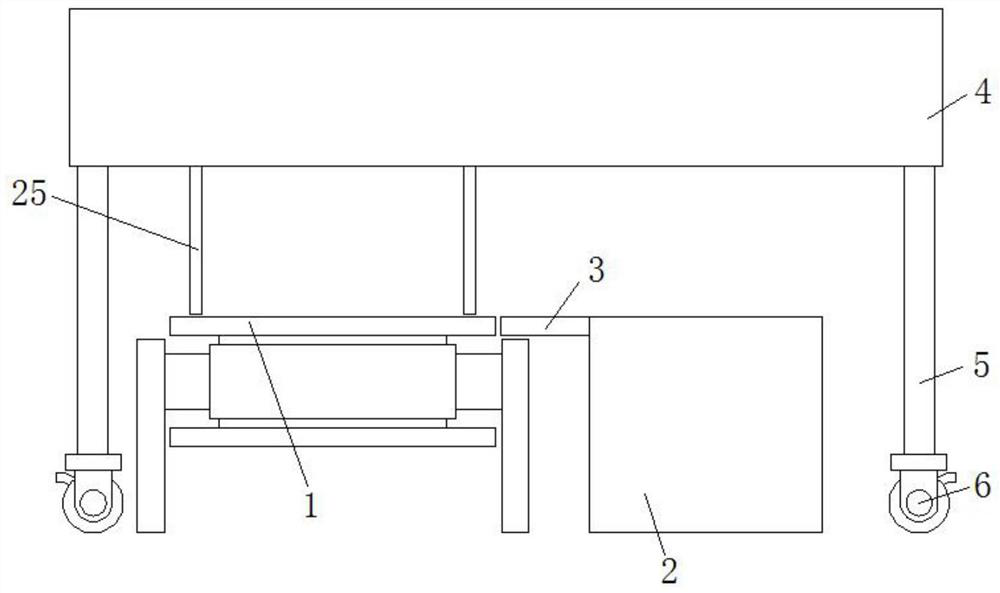

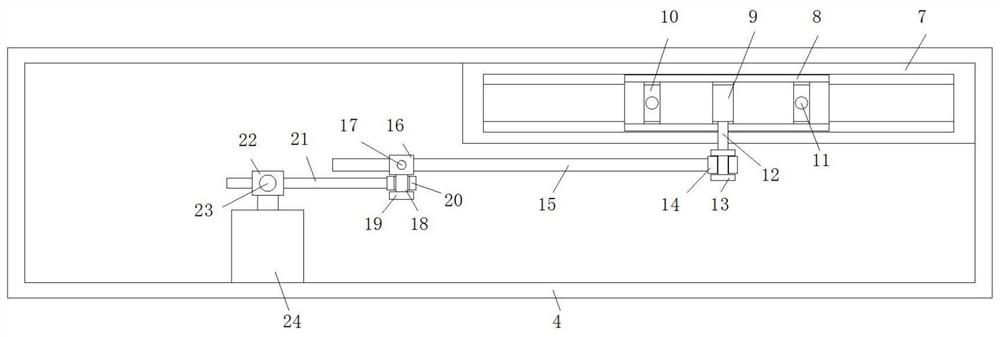

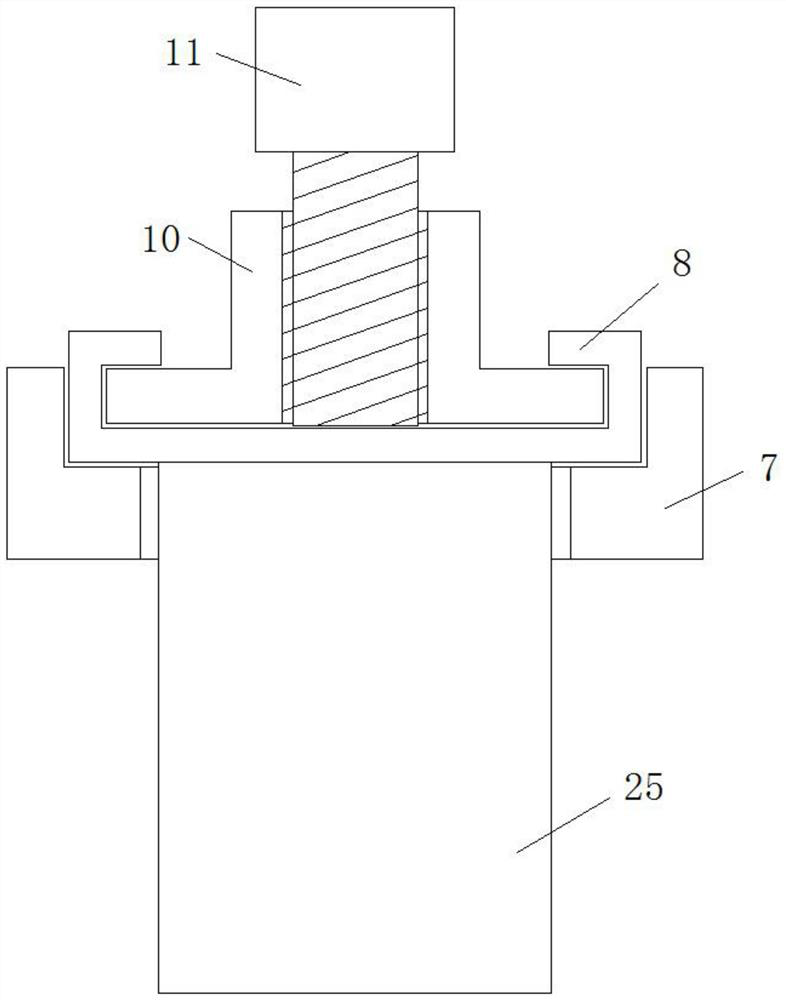

[0020] refer to Figure 1-3 , a detection tool for ferrite soft magnetic core product processing, including a transmission belt 1 and a processing table 2, an extension plate 3 is fixedly connected to the top of one side of the processing table 2, and one end of the extension plate 3 extends to one side of the transmission belt 1, The vertical top of the drive belt 1 is provided with a mounting frame 4, the mounting frame 4 is a rectangular frame-shaped structure, and a side inner wall of the mounting frame 4 is fixedly connected with a sliding seat 7, and the sliding seat 7 is provided with a vertical through hole, and the vertical through hole The top inner wall of the hole is provided with a side chute, the vertical through hole is provided with a sliding track plate 8, and the two ends of the sliding track plate 8 are slidably connected in the side chute respectively, and the top side of the sliding track plate 8 is provided with a top sliding track plate. The cross sectio...

Embodiment 2

[0023] In this embodiment, it is basically the same as Embodiment 1. More preferably, the four corners of the bottom of the mounting frame 4 are fixedly connected with legs 5, and the bottom ends of the legs 5 are equipped with locking universal wheels 6 to facilitate the movement and mobility of the equipment. Higher, connecting rod one 12 and connecting rod two 18 are cylindrical structures, realize the rotation of swivel one 14 and swivel two 20, the bottom ends of T-shaped slider one 9 and T-shaped slider two 10 are T Glyph structure, and the tops of T-shaped slider 1 9 and T-shaped slider 2 10 all extend to the top side of the sliding track plate 8, through locking bolt 1 11, locking bolt 2 17 and locking bolt 3 23, complete After the adjustment of T-shaped slide block two 10, sliding sleeve one 16 and sliding sleeve two 22, the bottom end of push plate 25 extends to the vertical below of slide seat 7, and push plate 25 promotes the ferrite soft magnetic core product move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com