Microchannel heat exchanger core applicable to gas turbine system

A technology of microchannel heat exchanger and gas turbine, which is applied in the direction of gas turbine devices, indirect heat exchangers, heat exchanger types, etc., can solve problems such as overheating of the intake system, achieve high heat exchange efficiency, increase fluid Re number, and withstand Excellent temperature and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

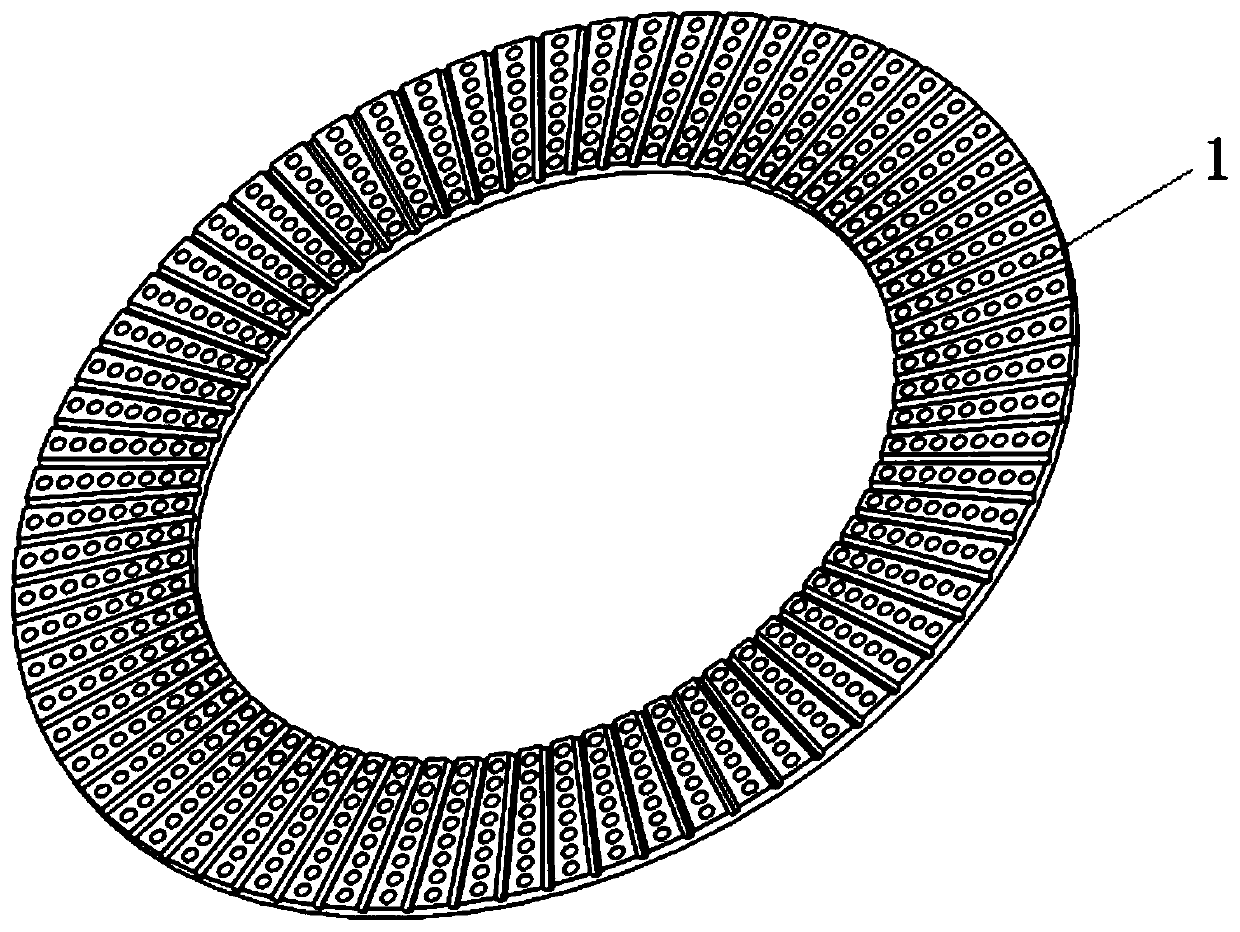

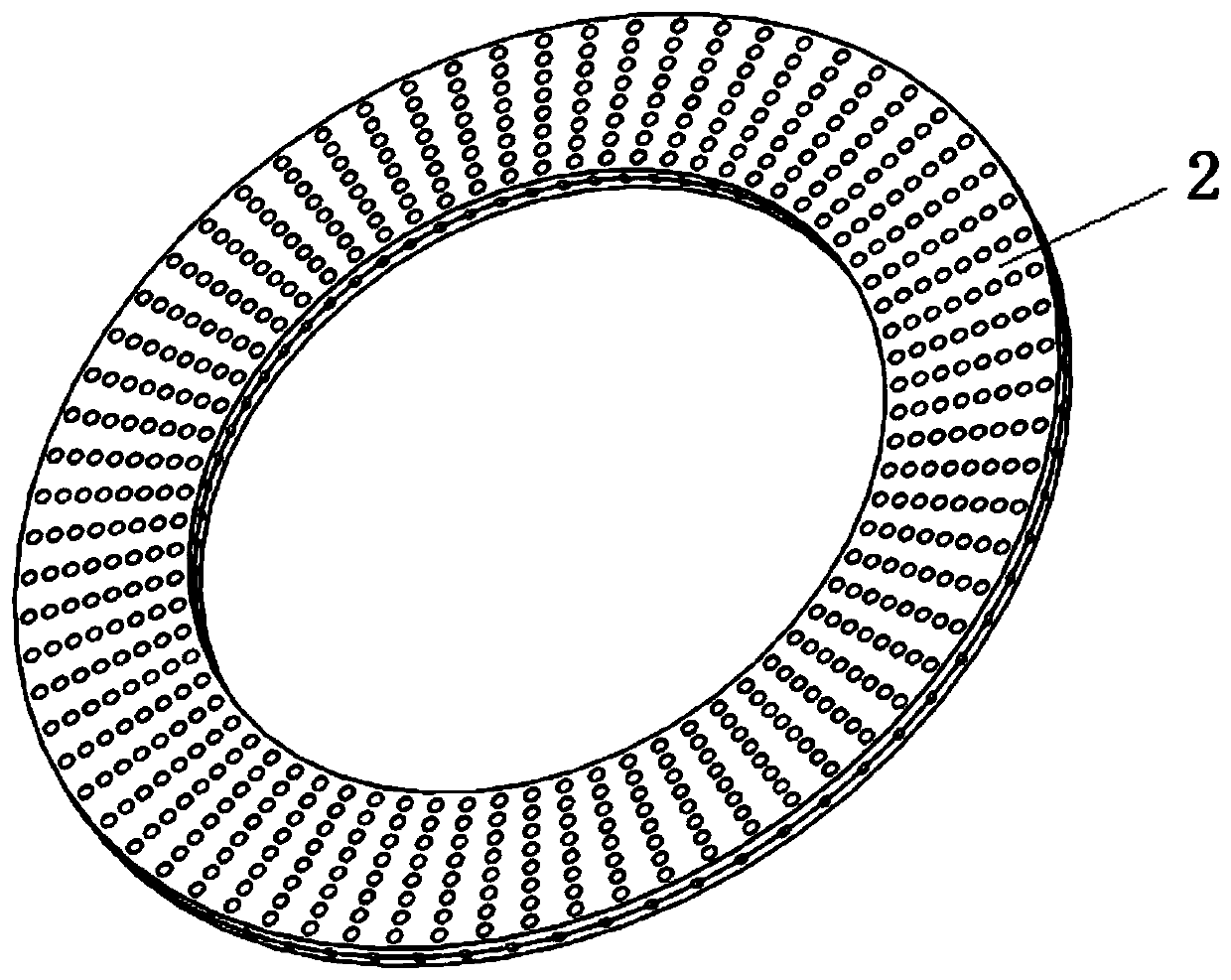

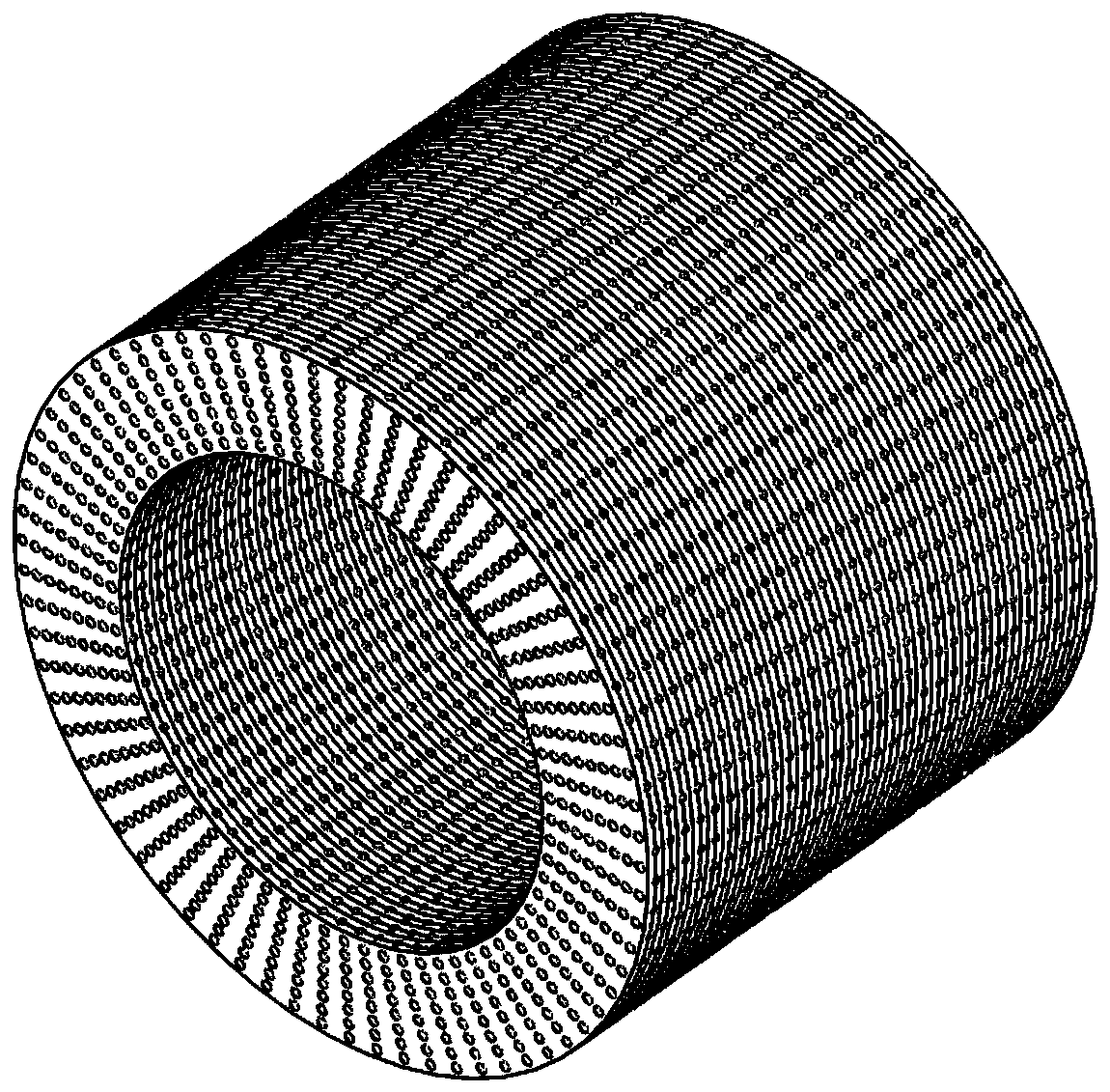

[0020] Specific implementation mode one: see Figure 1-6 This embodiment will be described. A microchannel heat exchanger core that can be used in a gas turbine system described in this embodiment includes 2n heat exchange core plates 1 and n heat exchange units 2, wherein n is an integer greater than or equal to 1, and the heat exchanger The thermal core plate 1 is in the shape of a ring, and the heat exchange core plate 1 is provided with a flow channel formed by etching or machining. 1-2mm, effectively improve the fluid flow state, increase the heat transfer coefficient of the heat exchanger, two heat exchange core plates 1 are assembled into a heat exchange unit 2, and the microchannel heat exchanger core for the gas turbine system Several heat exchange units 2 are connected by diffusion welding to form a cylindrical shape;

[0021] The core of the microchannel heat exchanger used in the gas turbine system is placed in front of the gas turbine compressor, and the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com