High-pressure water pump with compact volume

A high-pressure water pump, compact technology, applied in the field of high-pressure water pumps, can solve problems such as unstable commutation, unreliability, and affecting production efficiency, and achieve the effects of smooth operation, saving parts, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

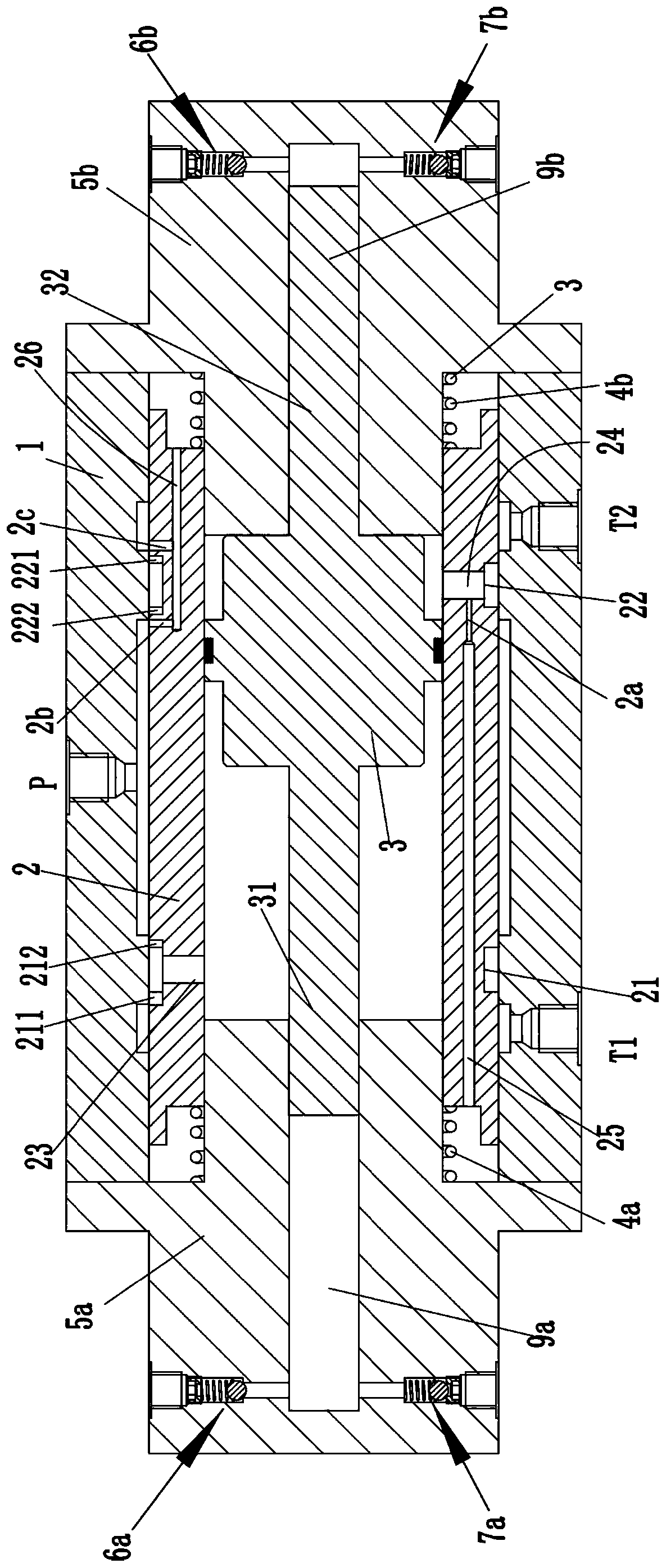

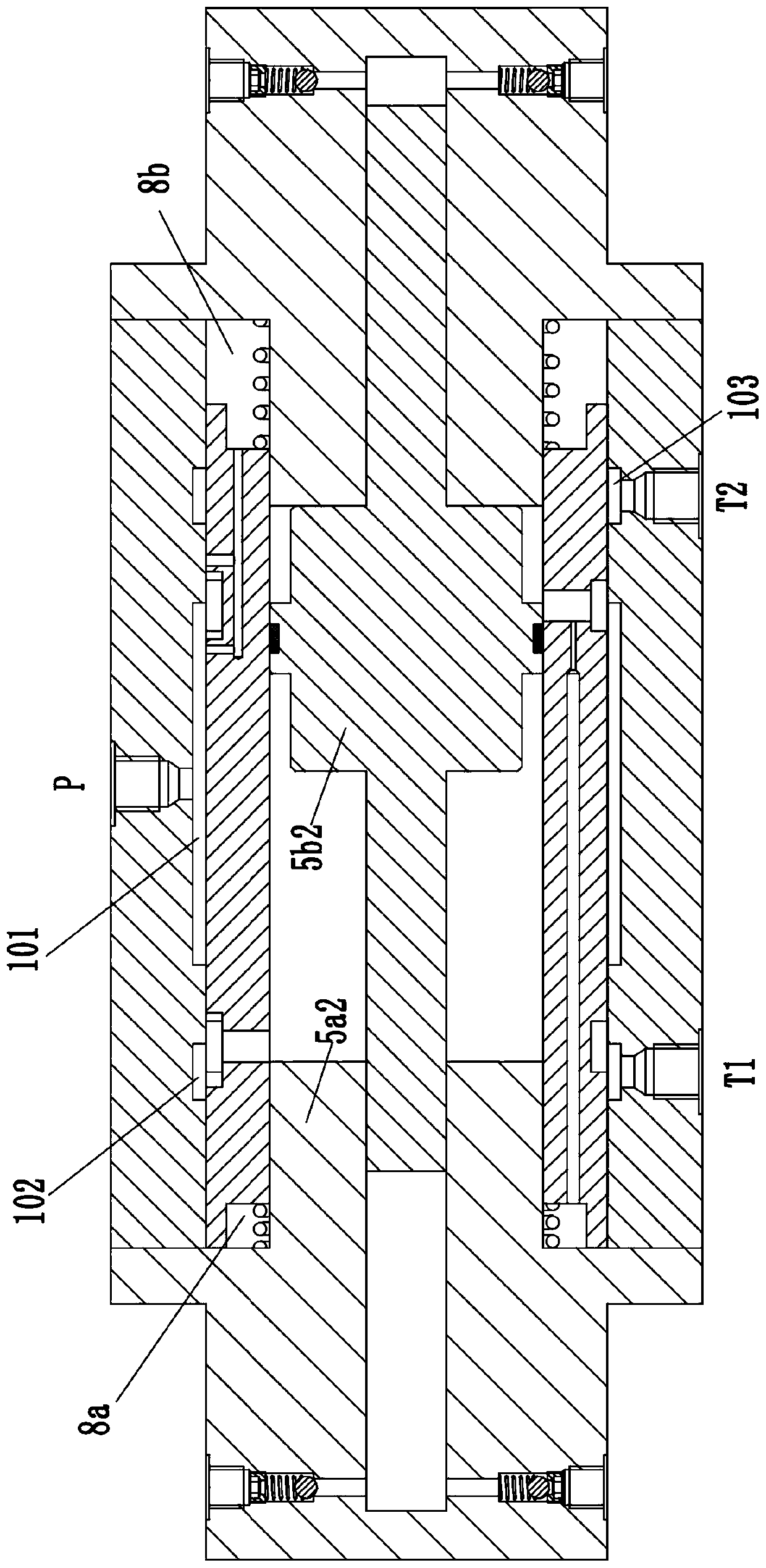

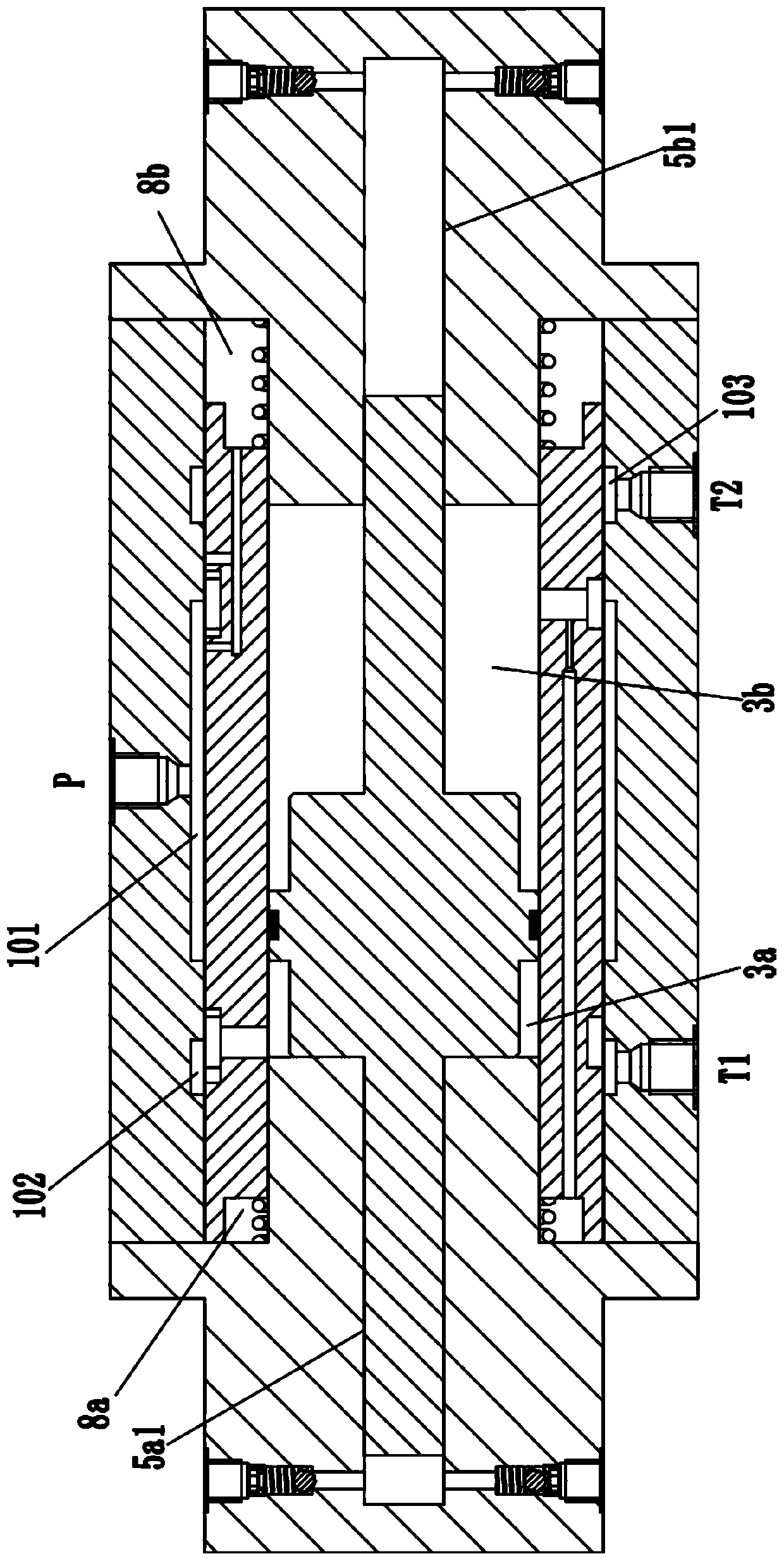

[0024] see Figure 1-6 As shown, a compact high-pressure water pump includes a pump body 1, the pump body 1 is provided with a left and right through installation hole 100, the left end of the pump body 1 is fixedly installed with a left end cover 5a, and the right end is fixedly installed with a right end Cover 5b; said installation hole 100 is provided with a left-moving piston body 3; said left end cover 5a is provided with a left plunger hole 5a1 with a right end opening along the axial direction of installation hole 100, and said right end cover 5b is installed along the inner edge The axial direction of hole 100 is provided with the right plunger hole 5b1 of left end opening, the left side of described piston body 3 is provided with the left plunger 31 that is slidably connected in the left plunger chamber, and the right side is provided with slidably connected with the right plunger. The right plunger 32 in the hole 5b1; the left plunger cavity 9a is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com