A coaxial liquid oxygen kerosene engine turbo pump structure

A technology for a kerosene pump and an engine, which is applied to the structure field of a coaxial liquid oxygen kerosene engine turbo pump, can solve the problems of high cost, large weight and space size, and a large number of turbo pump parts, and achieves safe operation, compact structure, The effect of reducing production, processing and testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

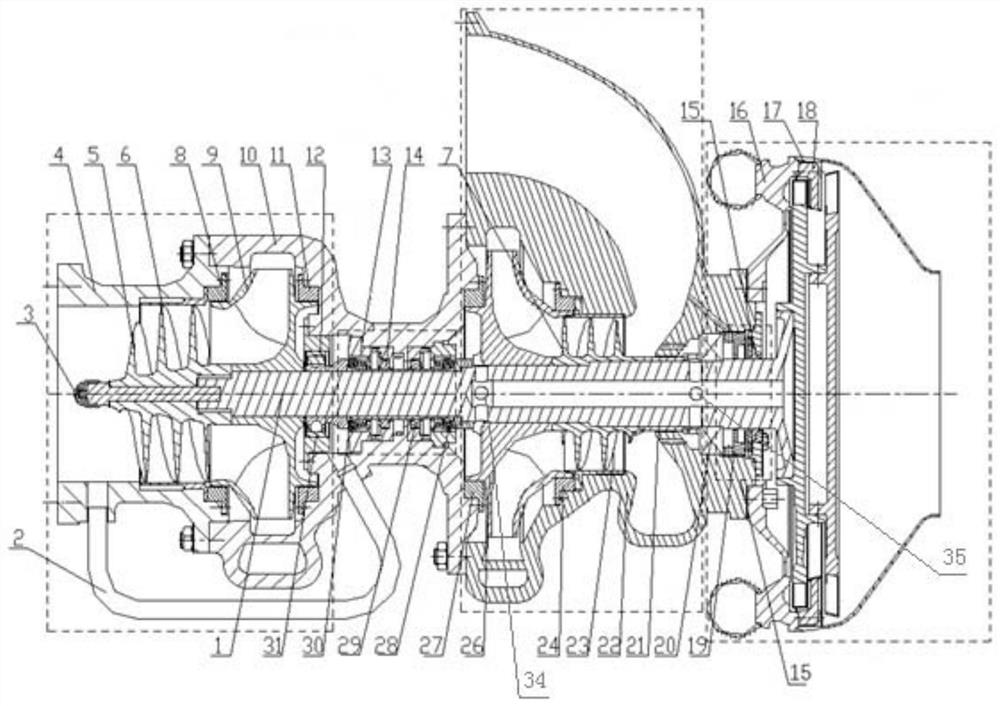

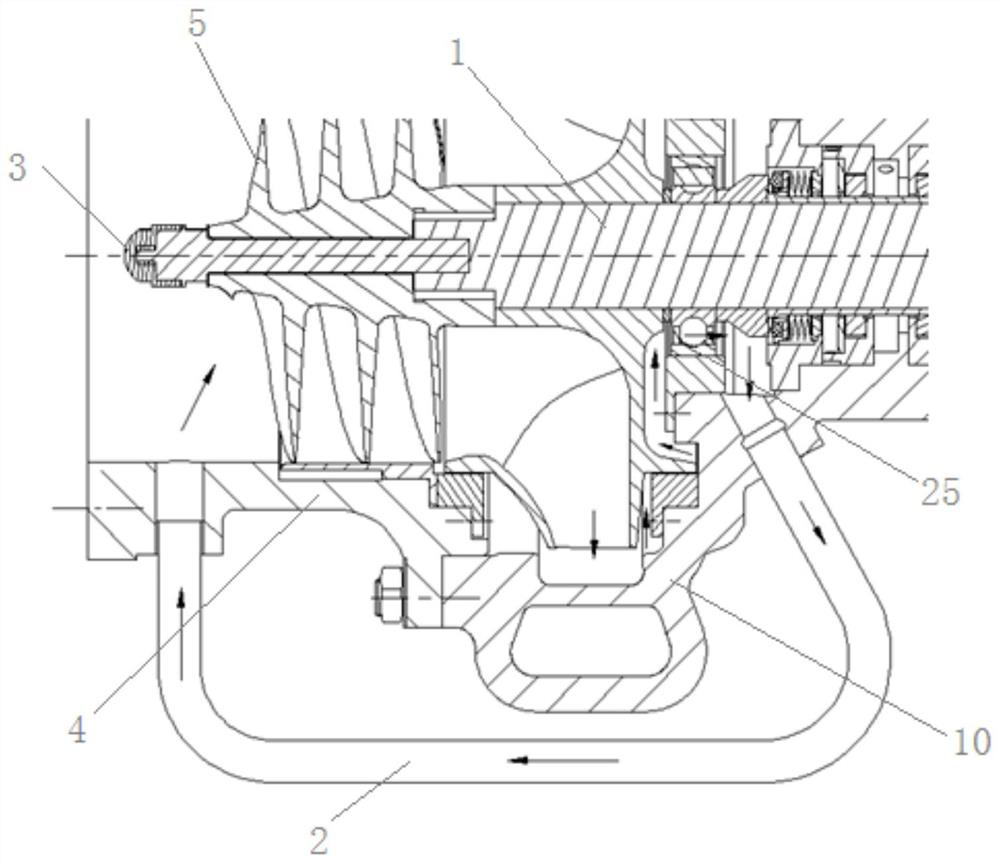

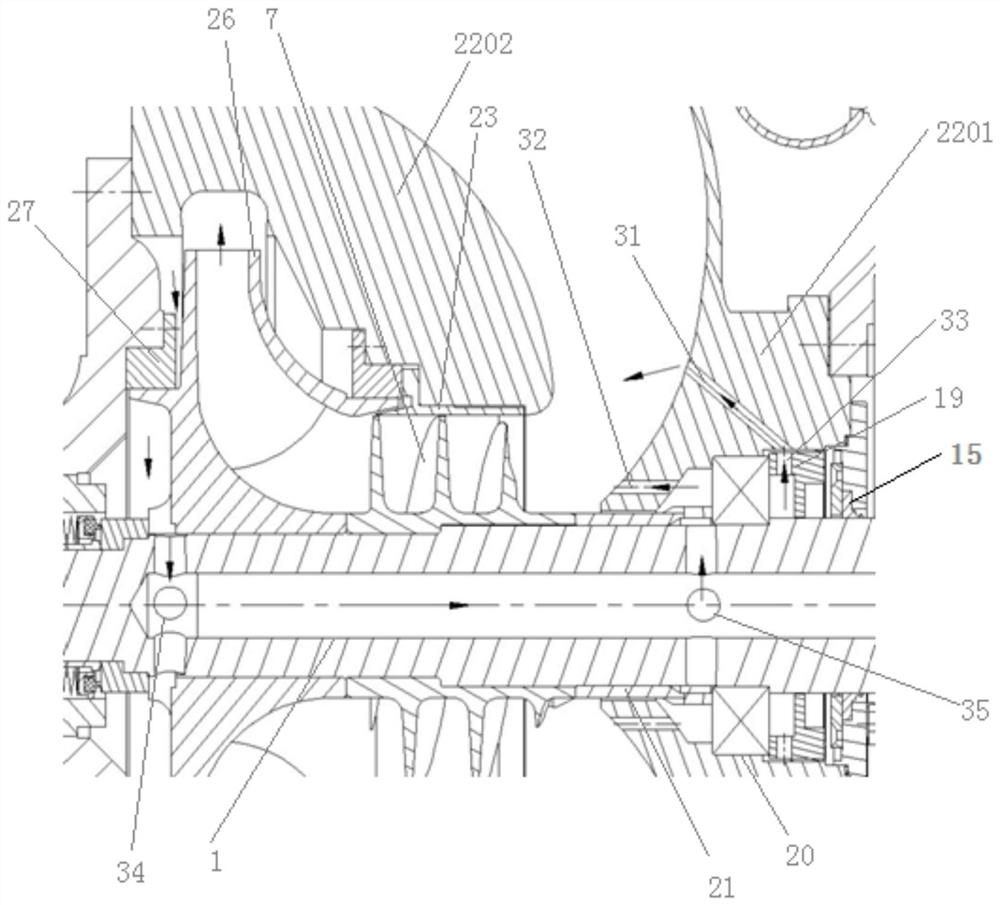

[0037] Such as Figure 1 to Figure 5 As shown, the present invention provides a coaxial liquid oxygen kerosene engine turbine pump structure, the kerosene pump is centered, the turbine and the oxygen pump are separated on both sides, and one turbine drives the oxygen pump and the kerosene pump at the same time, with compact structure and few parts, mainly composed of oxygen Pump, kerosene pump, turbine, seal between oxygen pump and kerosene pump, seal between turbine and kerosene pump.

[0038]The oxygen pump includes oxygen pump inlet pipe 4, oxygen pump inducer 5, oxygen pump guide sleeve 6, oxygen pump centrifugal wheel front seal ring 8, oxygen pump centrifugal wheel 9, oxygen pump housing 10, oxygen pump c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com