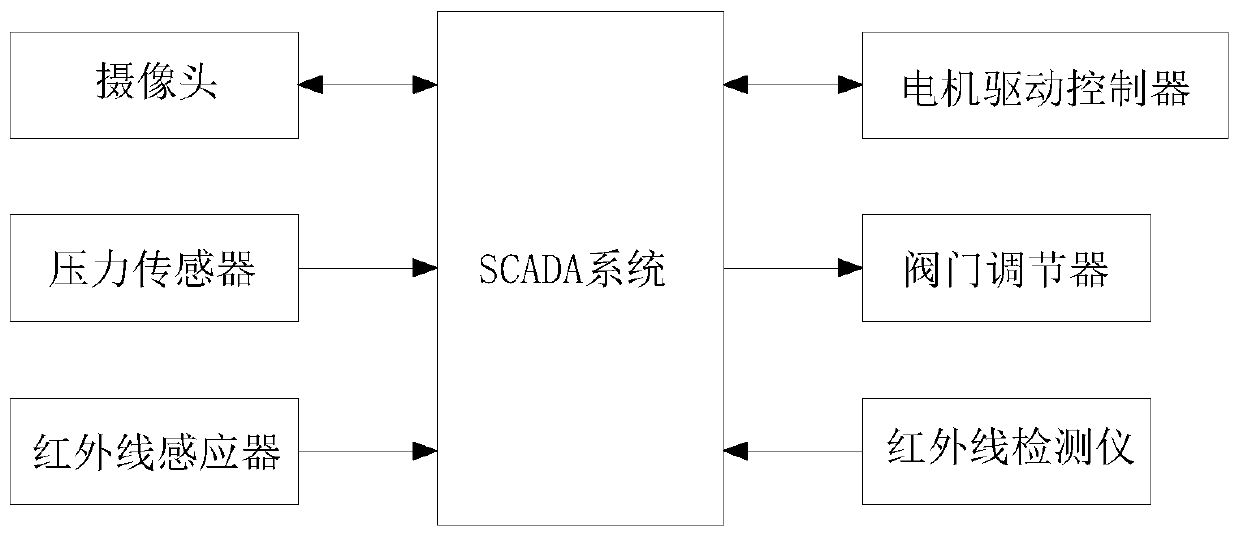

Polishing energy-saving control system and method

An energy-saving control system and rough polishing technology, which is applied in the field of polishing, can solve the problems of reduced grinding efficiency, increased brick grinding efficiency, and increased power consumption, so as to achieve the effect of reducing power consumption and electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Polishing is a necessary production process for grinding and cutting target objects (such as ceramic tiles, sanitary ware, etc.) to improve their gloss and flatness, so as to achieve beauty. Here, the operation of performing the polishing process on the target object is defined as polishing the target polishing body.

[0042] The polishing process includes three processes of rough polishing, intermediate polishing and fine polishing. The polishing equipment includes a grinding head, a grinding head motor that drives the grinding head to rotate, a grinding head cylinder that drives the grinding head to press down, and a grinding block installed on the grinding head. Each polishing process (each polishing process mentioned here refers to the three processes of rough polishing, medium polishing and fine polishing) includes multiple sets of polishing equipment, that is, each polishing process requires multiple polishing, according to the running direction of the conveyor bel...

Embodiment 2

[0076] Embodiment 2 provides a polishing energy-saving control method. Polishing is a process of grinding and cutting the target polishing body. The polishing process includes three processes of rough polishing, medium polishing and fine polishing. The polishing equipment includes a grinding head, a driving grinding head The rotating grinding head motor, the grinding head cylinder driving the grinding head to press down, and the grinding block installed on the grinding head, each polishing process includes multiple sets of polishing equipment. Please refer to Figure 5 As shown, the polishing energy-saving control method includes the following steps:

[0077] S110. Send a first signal to each valve regulator, so that each grinding head cylinder outputs a corresponding preset air pressure value; send a second signal to each motor drive controller, so that each grinding head motor outputs a corresponding preset speed;

[0078] S120. Receive the polishing image obtained by taki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com