Aftertreatment device for producing polyvinyl alcohol powder

A technology of polyvinyl alcohol powder and post-processing device, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low work efficiency, time-consuming and laborious, etc., and achieve the effect of simple structure, convenient use, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

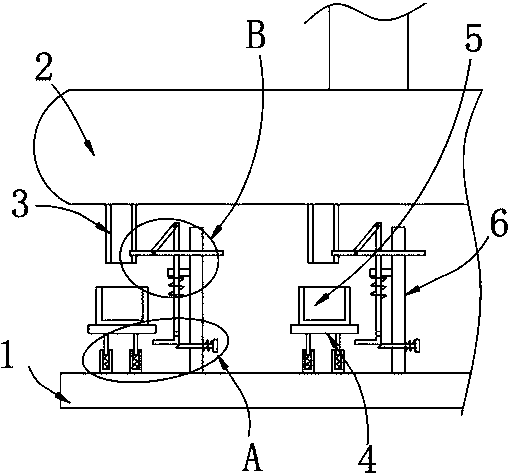

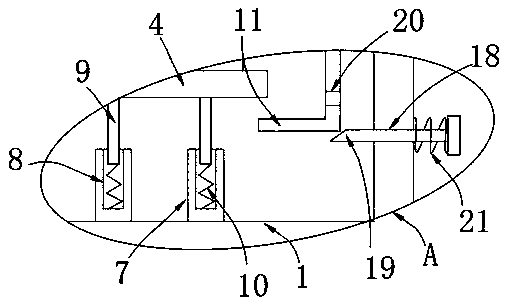

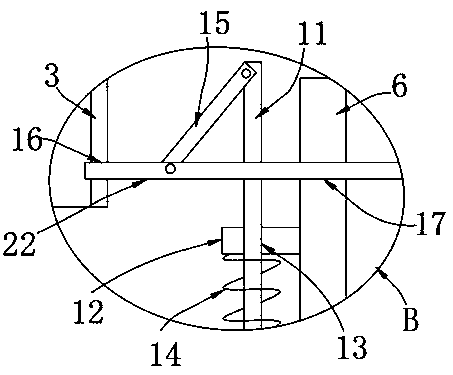

[0024] refer to Figure 1-4 , a post-processing device for producing polyvinyl alcohol powder, comprising a bottom plate 1, the top side of the bottom plate 1 is provided with a fixed rod 6, the bottom plate 1 is provided with a storage tank 2, and the storage tank 2 is provided with a discharge pipe 3, The top side of the bottom plate 1 is movably equipped with a placement plate 4, the top side of the placement plate 4 is placed with a packaging barrel 5, and one side of the fixed rod 6 is movably installed with an L-shaped pull rod 11, and one side of the L-shaped pull rod 11 is in contact with the placement plate 4. Adaptation, the top of the L-shaped tie rod 11 is rotatably equipped with a connecting rod 15, and one end of the connecting rod 15 is rotatably installed with a sealing plate 22, and a movable hole 16 is opened on the inner wall of one side of the discharge pipe 3, and one side of the sealing plate 22 runs through Active hole 16.

[0025] In the present invent...

Embodiment 2

[0030] refer to Figure 1-4 , a post-processing device for producing polyvinyl alcohol powder, comprising a bottom plate 1, the top side of the bottom plate 1 is provided with a fixed rod 6, the bottom plate 1 is provided with a storage tank 2, and the storage tank 2 is provided with a discharge pipe 3, The top side of the bottom plate 1 is movably equipped with a placement plate 4, the top side of the placement plate 4 is placed with a packaging barrel 5, and one side of the fixed rod 6 is movably installed with an L-shaped pull rod 11, and one side of the L-shaped pull rod 11 is in contact with the placement plate 4. Adaptation, the top of the L-shaped tie rod 11 is installed with a connecting rod 15 through the rotation of the pin shaft, and one end of the connecting rod 15 is installed with a sealing plate 22 through the rotation of the pin shaft, and a movable hole 16 is provided on the inner wall of one side of the discharge pipe 3 to seal One side of the plate 22 runs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com