Anti-static screen protection film and preparation method thereof

A screen protector, anti-static technology, applied in conductive coatings, epoxy coatings, polycarbonate coatings, etc., can solve the problems of weak impact resistance and durability, and achieve improved impact resistance, high hardness, and improved The effect of interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

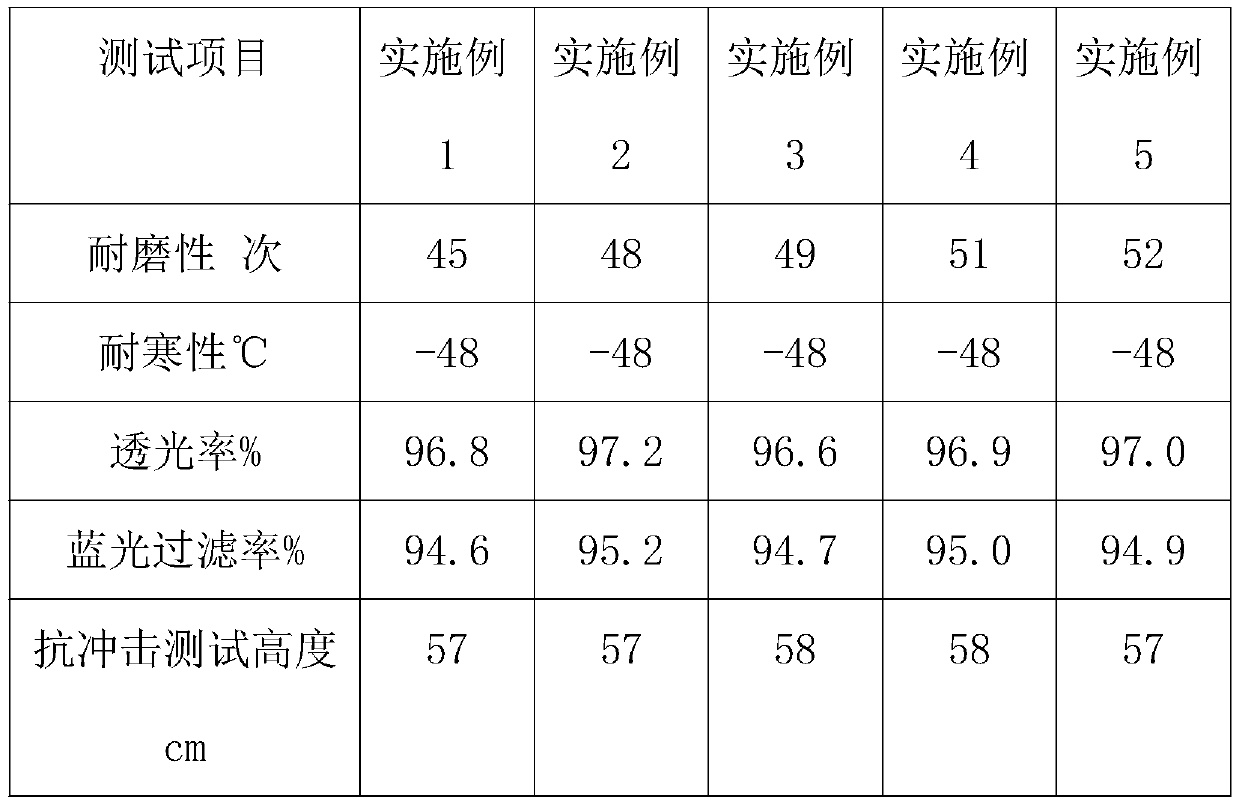

Examples

Embodiment 1

[0026] 1) The coating of the hardened coating 2 is configured, and the coating of the hardened coating 2 is composed of the following components: 20 parts by weight of polyurethane acrylate, 15 parts by weight of acrylate containing hydroxyl, 2 parts of decyltrimethoxysilane, cross-linked 1 part by weight of agent, 5 parts by weight of coupling agent, 8 parts by weight of nano-organic montmorillonite, 0.2 part by weight of photoinitiator, 0.5 part by weight of leveling agent, and 80 parts by weight of organic solvent;

[0027] 2) configure the coating of the hardened coating 4, the coating of the hardened coating 4 is made up of the following components: 10 parts by weight of polyurethane acrylate, 15 parts by weight of corundum micropowder, 10 parts by weight of acrylate containing hydroxyl, 1 part by weight of crosslinking agent , 1 part by weight of coupling agent, 0.2 part by weight of photoinitiator, 0.5 part by weight of leveling agent, 80 parts by weight of organic solve...

Embodiment 2

[0035] 1) The coating of the hardened coating 2 is configured, and the coating of the hardened coating 2 is composed of the following components: 50 parts by weight of polyurethane acrylate, 30 parts by weight of acrylate containing hydroxyl, 5 parts of decyltrimethoxysilane, cross-linked 5 parts by weight of agent, 15 parts by weight of coupling agent, 12 parts by weight of nano-organic montmorillonite, 0.8 parts by weight of photoinitiator, 2 parts by weight of leveling agent, 120 parts by weight of organic solvent;

[0036] 2) configure the coating of the hardened coating 4, the coating of the hardened coating 4 is made up of the following components: 30 parts by weight of polyurethane acrylate, 20 parts by weight of corundum micropowder, 15 parts by weight of acrylate containing hydroxyl, 5 parts by weight of crosslinking agent , 3 parts by weight of coupling agent, 0.8 parts by weight of photoinitiator, 2 parts by weight of leveling agent, 10 parts by weight of blue light ...

Embodiment 3

[0044] 1) Configure the coating of the hardened coating 2, which is composed of the following components: 30 parts by weight of urethane acrylate, 20 parts by weight of hydroxyl-containing acrylate, 3 parts of decyltrimethoxysilane, cross-linked 2 parts by weight of agent, 8 parts by weight of coupling agent, 10 parts by weight of nano-organic montmorillonite, 0.4 parts by weight of photoinitiator, 1 part by weight of leveling agent, 100 parts by weight of organic solvent;

[0045] 2) configure the coating of the hardened coating 4, the coating of the hardened coating 4 is made up of the following components: 20 parts by weight of polyurethane acrylate, 17 parts by weight of corundum micropowder, 12 parts by weight of acrylate containing hydroxyl, 2 parts by weight of crosslinking agent , 2 parts by weight of coupling agent, 0.4 parts by weight of photoinitiator, 1 part by weight of leveling agent, 9 parts by weight of blue light absorber Owende TM479, 100 parts by weight of or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com