Scanning probe and preparation method thereof

A technology of scanning probes and probes, which is applied in the field of scanning probes and its preparation, can solve problems such as damage between the needle tip and the sample, large distance, and limitation of the application range of STM, and achieve excellent wear resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

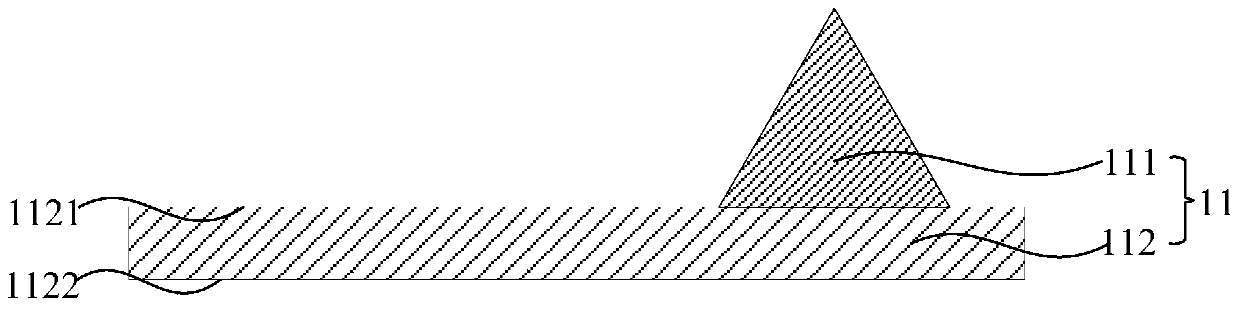

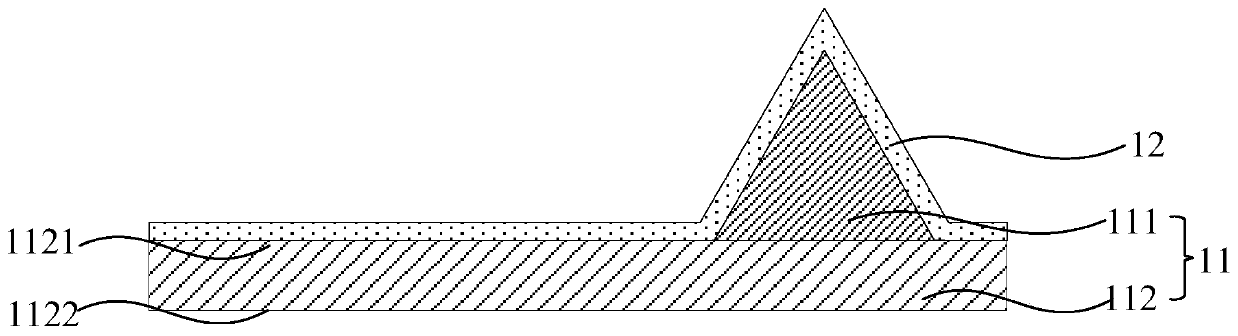

[0051] Such as Picture 9 As shown, the present invention provides a novel scanning probe. The scanning probe includes a probe body 11, which includes a needle tip 111 and a micro cantilever 112 that carries the needle tip 111. The micro cantilever 112 is provided with an upper surface 1121 and an upper surface 1121. The surface corresponds to the lower surface 1122, the tip 111 is connected to the upper surface 1121 of the microcantilever near the end; the conductive metal layer 12 covering the upper surface 1121 of the microcantilever and the tip 111; the insulating layer 13 covering the conductive metal layer 12; covering the lower surface of the microcantilever 1122 of the metal reflective layer 14.

[0052] As an example, the probe body 11 is composed of a micro cantilever 112 and a sharp tip 111 at the end of the micro cantilever. The length of the micro cantilever includes 100 to 500 μm, the width includes 5 to 20 μm, and the thickness includes 500 nm to 5 μm. The material...

Embodiment 2

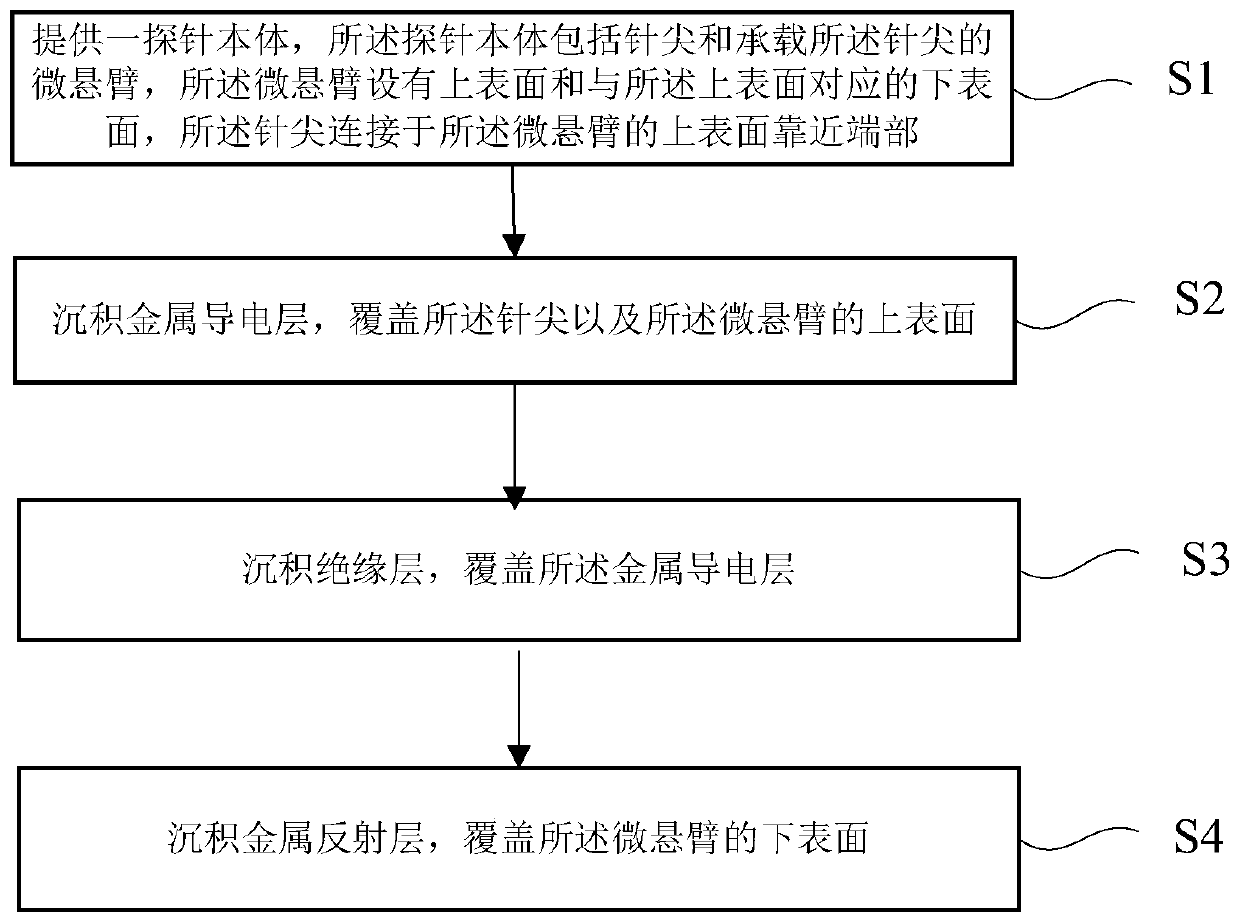

[0059] Please refer to figure 1 , The present invention provides a method for preparing a novel probe, the method for preparing the novel probe includes the following steps:

[0060] 1) A probe body is provided. The probe body includes a needle tip and a micro cantilever carrying the needle tip. The micro cantilever is provided with an upper surface and a lower surface corresponding to the upper surface. The needle tip is connected to the The upper surface of the micro cantilever is close to the end;

[0061] 2) Depositing a first conductive metal layer, which covers the tip and the upper surface of the microcantilever;

[0062] 3) Depositing an insulating layer to cover the first metal conductive layer;

[0063] 4) Depositing a metal reflective layer to cover the lower surface of the microcantilever.

[0064] Combine the attachment below Figure 2 to 9 The technical solution of this embodiment is described in detail.

[0065] Such as figure 2 As shown, step 1) is performed to provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com