Tower crane fault diagnosis system

A technology of fault diagnosis system and tower crane, applied in general control system, control/adjustment system, instrument, etc., can solve problems such as low efficiency of fault judgment and difficulty in fault diagnosis of tower crane, realize real-time monitoring, reduce difficulty, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

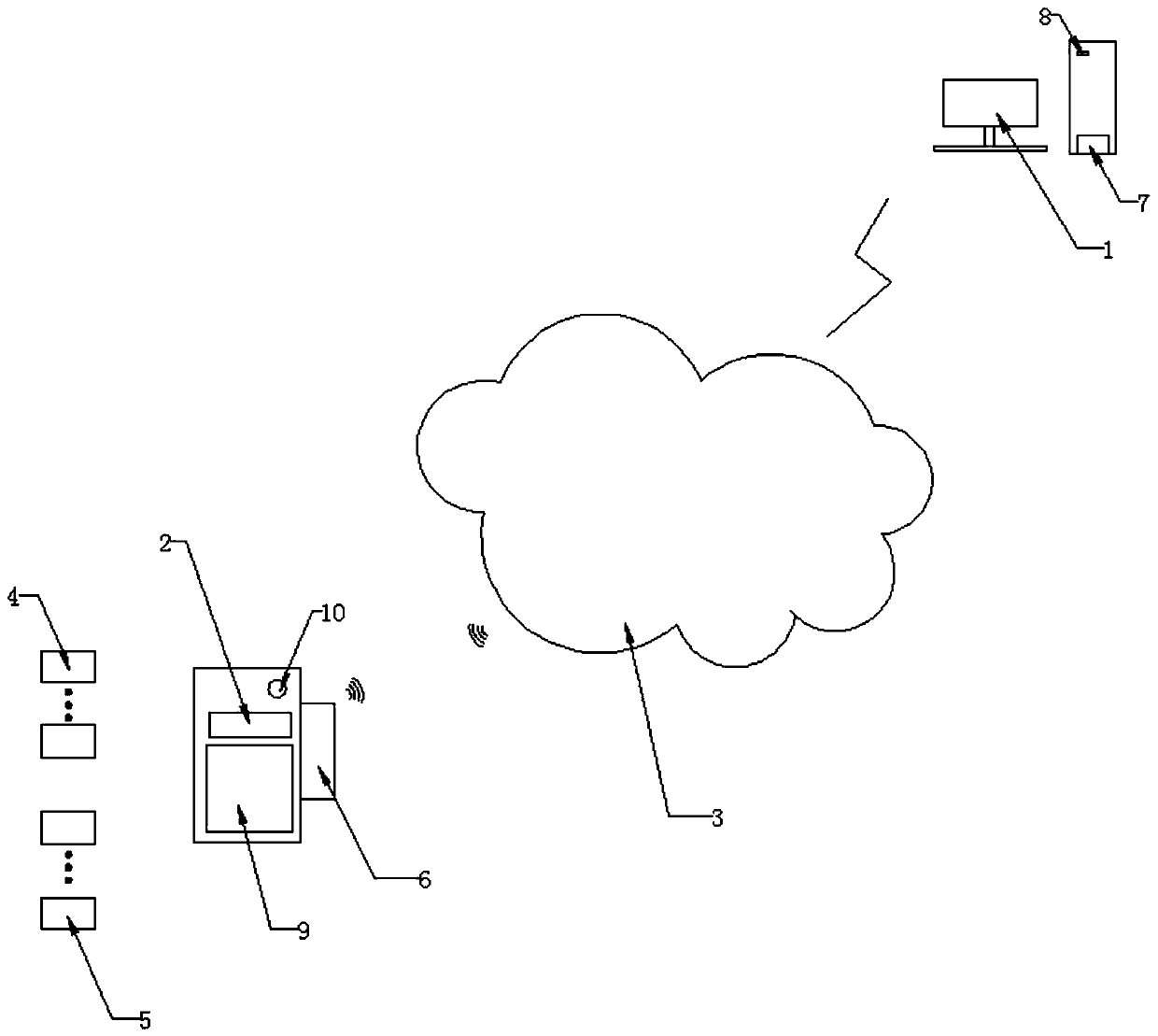

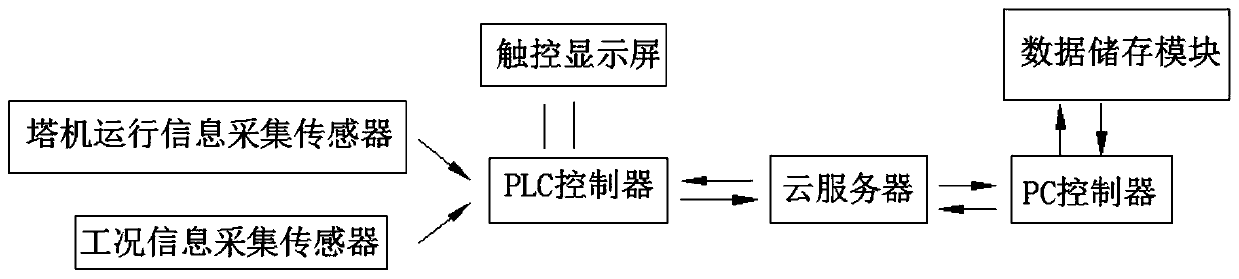

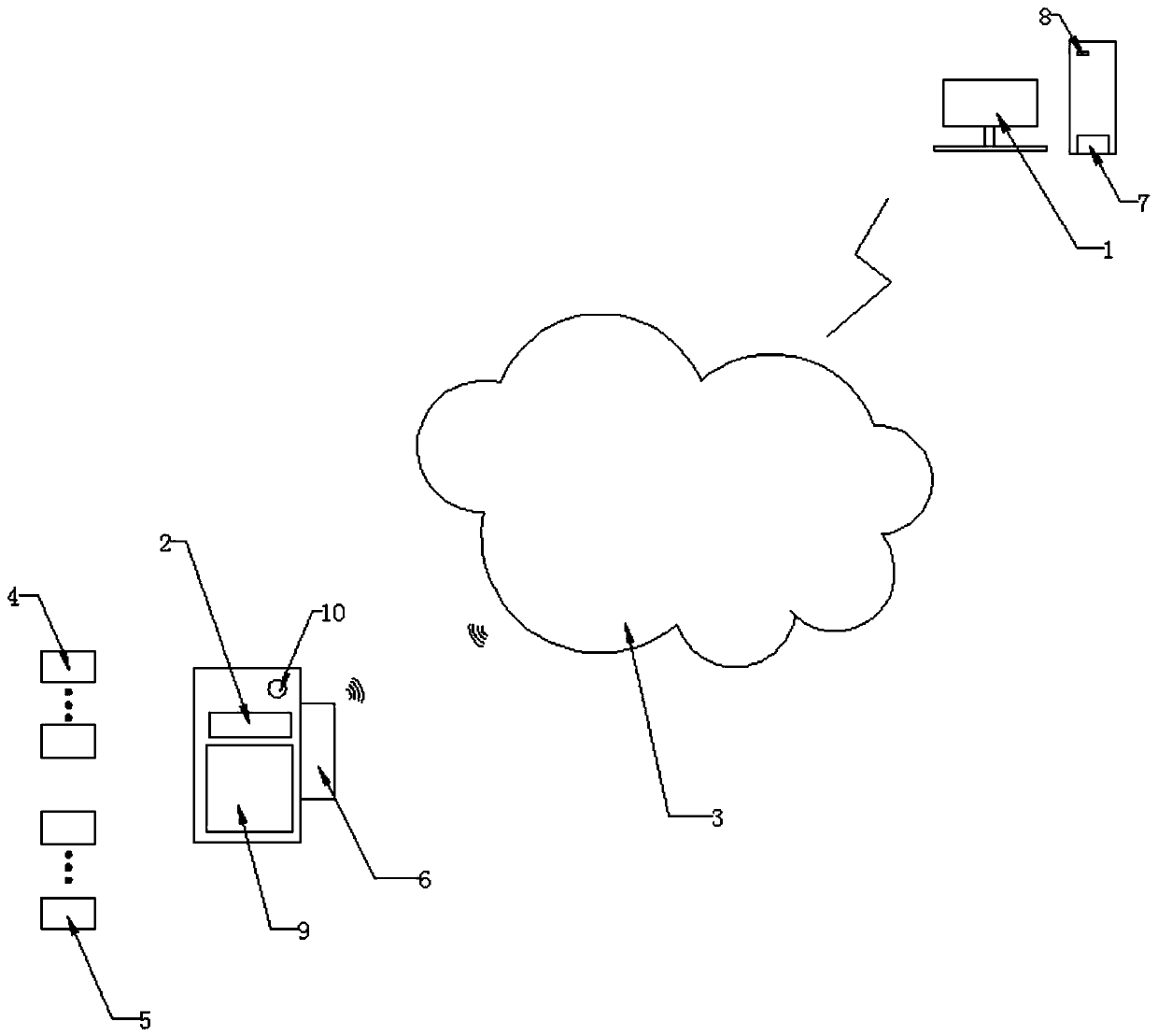

[0024] This embodiment, as the basic embodiment of the present invention, discloses a tower crane fault diagnosis system, the specific structure is as follows figure 1 and figure 2 As shown, it includes a PC controller 1, a PLC controller 2, a cloud server 3, a working condition information collection sensor 4 for collecting working condition information parameters, and a tower crane operation information collection sensor 4 for collecting actual operating parameters of the tower crane. Among them, the working condition information acquisition sensor 3 includes a wind speed sensor and a temperature sensor for detecting the environment where the tower crane is located, a tension sensor for detecting the weight of the heavy object lifted by the tower crane, a speed sensor for detecting the lifting speed of the hook and detecting the rotation angle of the tower crane. At the same time, according to the different environments where the tower crane is located, data that has a sign...

Embodiment approach 2

[0028] This embodiment, as a preferred embodiment of the present invention, discloses a tower crane fault diagnosis system, the specific structure is as follows figure 1 and figure 2 As shown, it includes a PC controller 1, a PLC controller 2, a cloud server 3, a working condition information collection sensor 4 for collecting working condition information parameters, and a tower crane operation information collection sensor 5 for collecting actual operating parameters of the tower crane. Its PC controller 1 is provided with a data storage module 7 and a USB data transfer interface 8, thereby downloading and saving the data stored in the cloud server 3;

[0029] Further, the fault diagnosis system also includes a touch screen 9 arranged in the cab of the tower crane, the touch screen 9 communicates with the PLC controller 2 through the 485 bus communication technology, and the output of the PLC controller 2 The end is also connected with a sound and light alarm device 10; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com