Electric oven

A technology for electric ovens and ovens, used in baking, oven doors/flap gates, baked goods, etc., can solve problems such as increased demand for oven recovery, impact on electrical components, and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

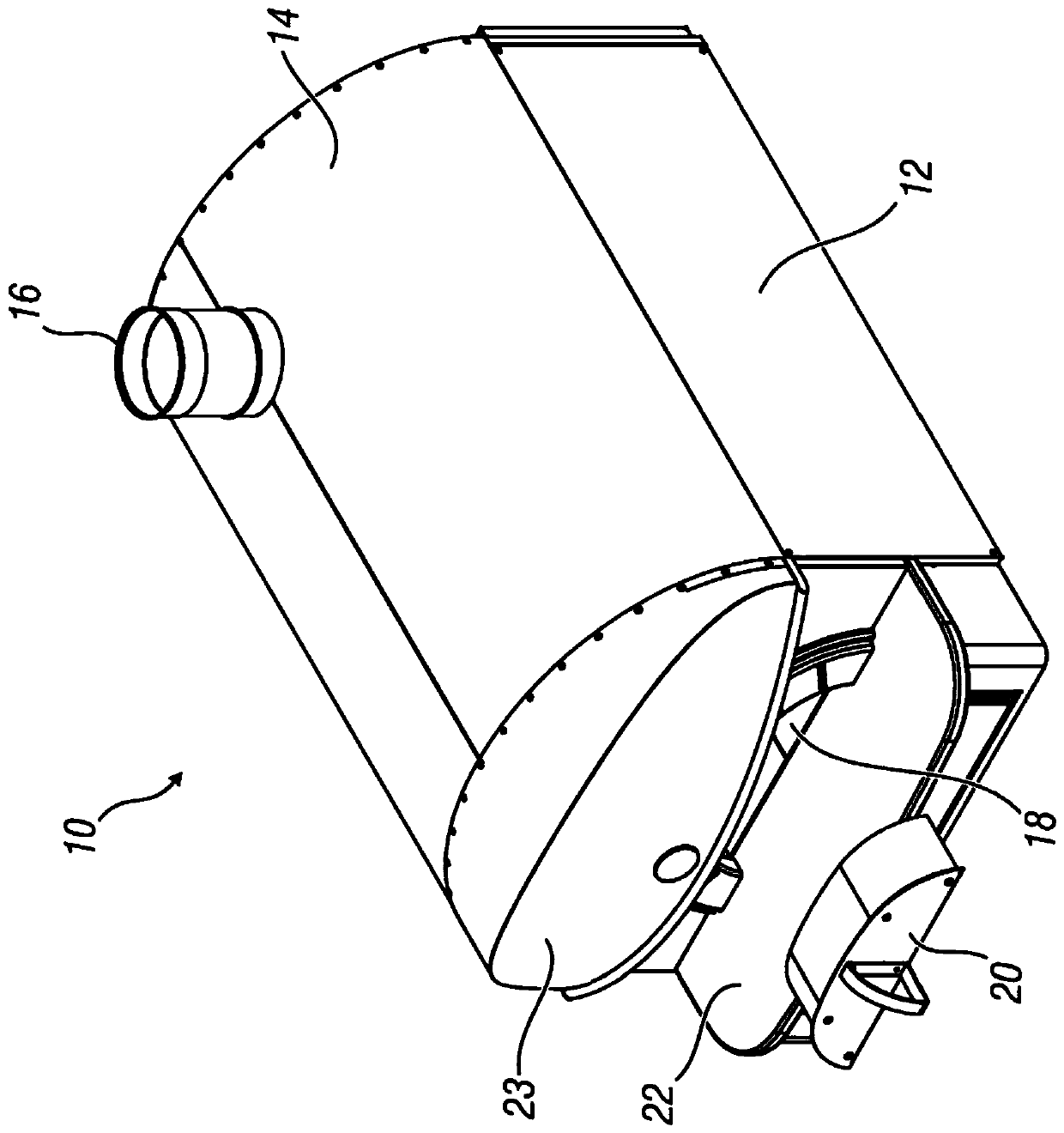

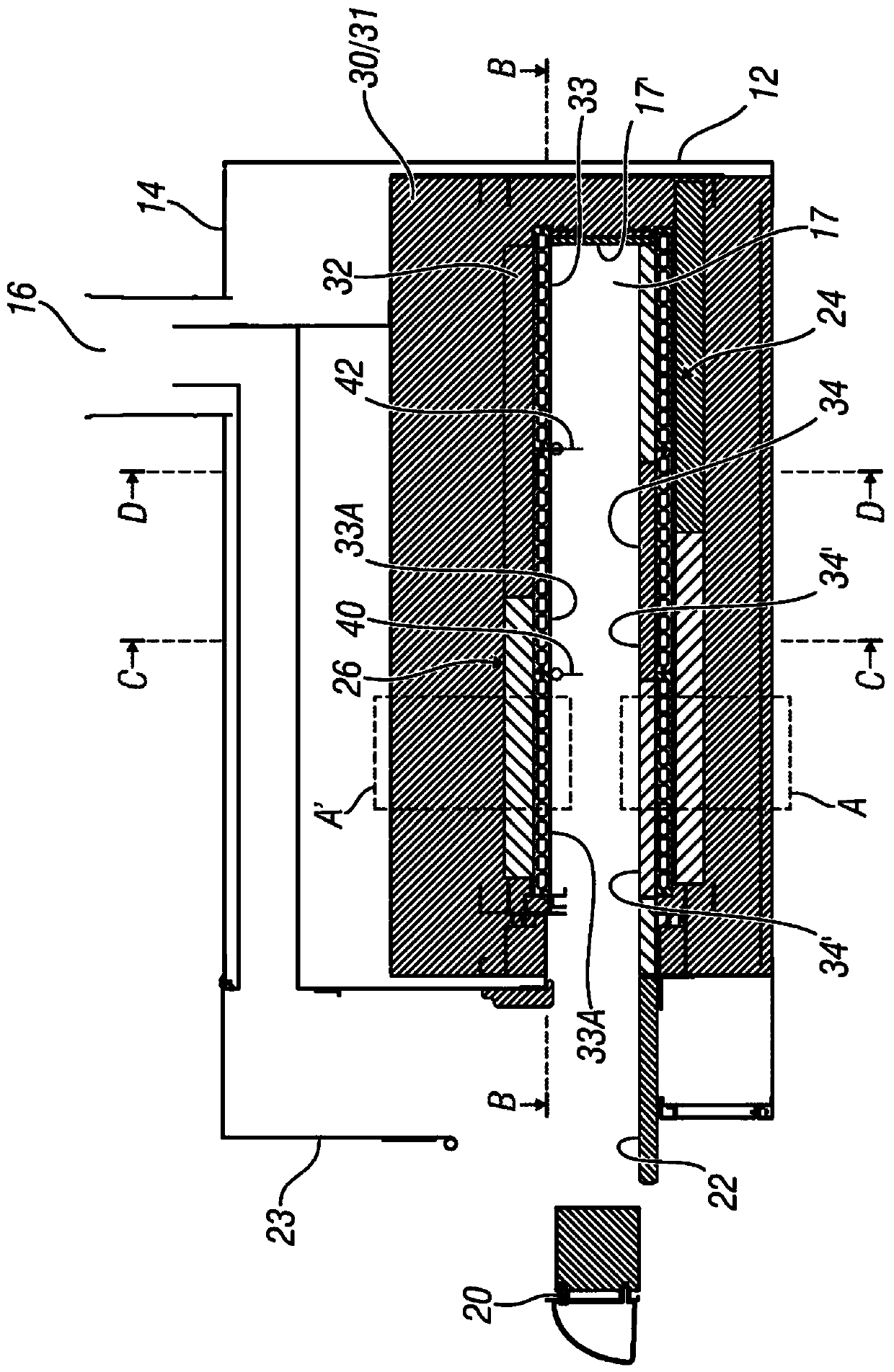

[0037] With reference to the figures referred to, there is generally indicated by reference numeral 10 an electric oven enhanced according to the invention, comprising: an oven body 12 and a dome or dome 14 surrounding an oven cavity or cooking cavity 17; the flue flue 16; the mouth 18 for entering the oven cavity 17, which can be closed by means of a door 20; the dish support plane 22 placed on the outside of the mouth 18; and (if any) a cover Body 23.

[0038] The oven cavity or cooking cavity 17 comprises an oven floor 24 and a cooking vault 26 which, as detailed below, houses the electrical resistors necessary for heating the oven.

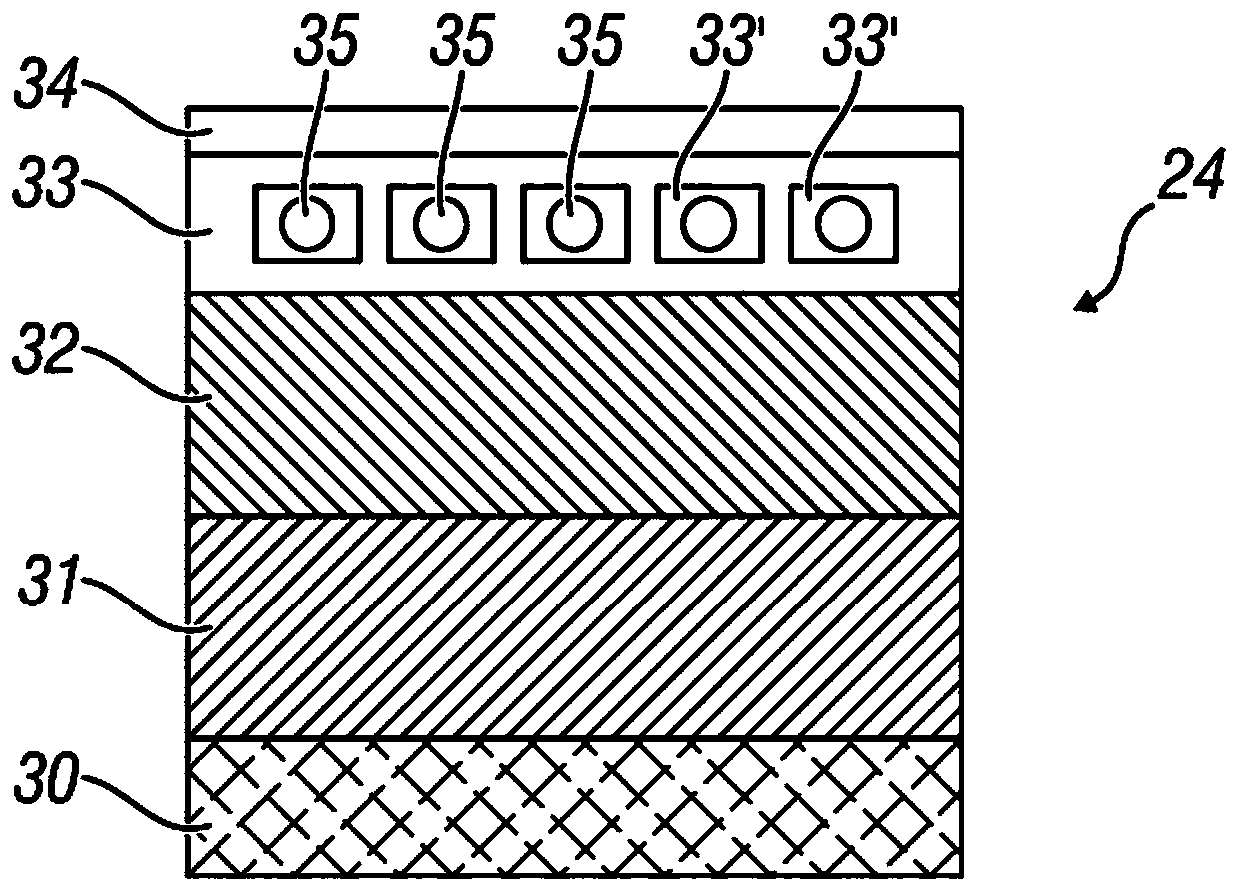

[0039] Consider oven floor 24 and refer to image 3 , image 3 A part of said bottom layer is specified in , the bottom layer of the oven comprises at least one first low temperature layer 30 (lowermost layer, opposite to the dish support surface facing the cooking vault 26; this layer is optional); the second layer 31, the second layer 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com