High slope blasting excavation dust falling method

A technology for dust reduction and slope, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as not being raised, and achieve the effects of facilitating repair and maintenance, reducing construction costs, and reducing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

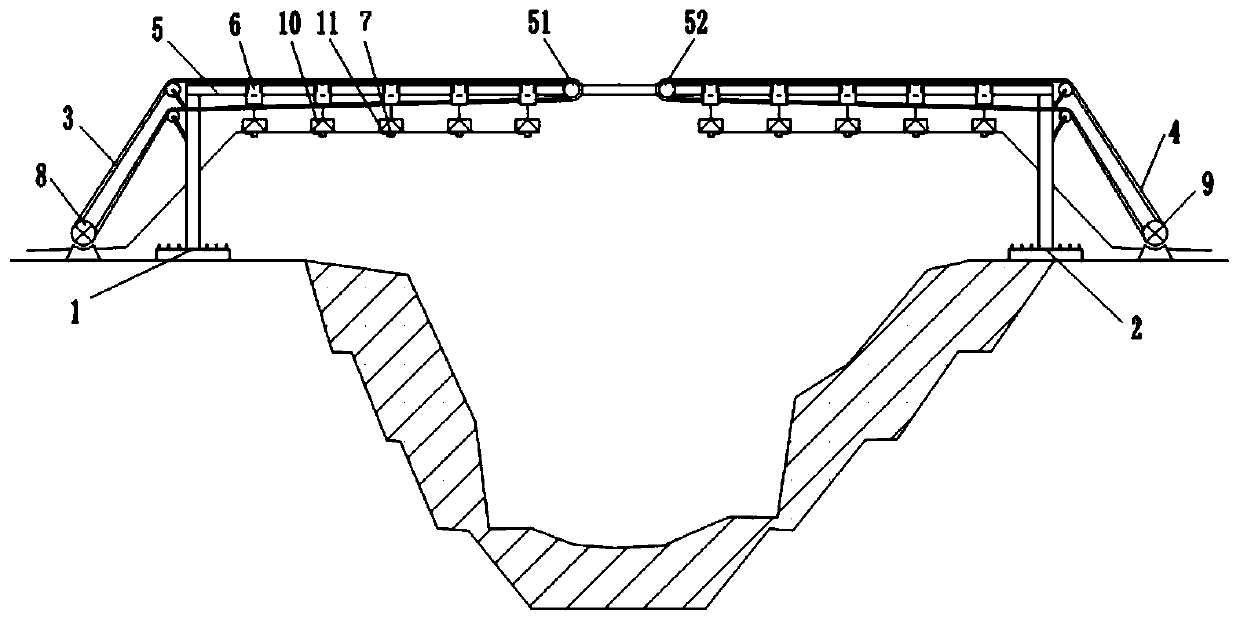

[0058] The dam site of Huangzangsi Water Conservancy Project in Heihe River, Qinghai Province is 25km away from Qilian County, Qinghai Province. Bottom hole dam section and power generation diversion dam section, etc.) are Class 2 buildings, and the powerhouse behind the dam does not participate in water retaining, and is a Class 4 building.

[0059] The dead water level of Huangzangsi Reservoir in Heihe, Qinghai is 2580.00m, and the corresponding dead storage capacity is 61 million m3 (effective); the normal water storage level is 2628.00 m, the effective storage capacity below the normal water storage level is 333 million m3, and the adjusted storage capacity is 295 million m3; the design flood water level is 2628.00 m , the verified flood level is 2628.70m, the total storage capacity of the reservoir is 403 million m3 (original), the flood control storage capacity is 080 million m3, and the installed capacity of the power station is 49MW.

[0060] According to the excavatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com