Waste sorting and conveying equipment

A kind of conveying equipment and sorting technology, which is applied in the direction of solid separation, separation of solids from solids by air flow, recycling technology, etc. It can solve the problems of wasting resources, hindering the movement of light materials, and wasting resources, so as to improve the processing efficiency. Speed and efficiency, improved practicability and adaptability, low manufacturing cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

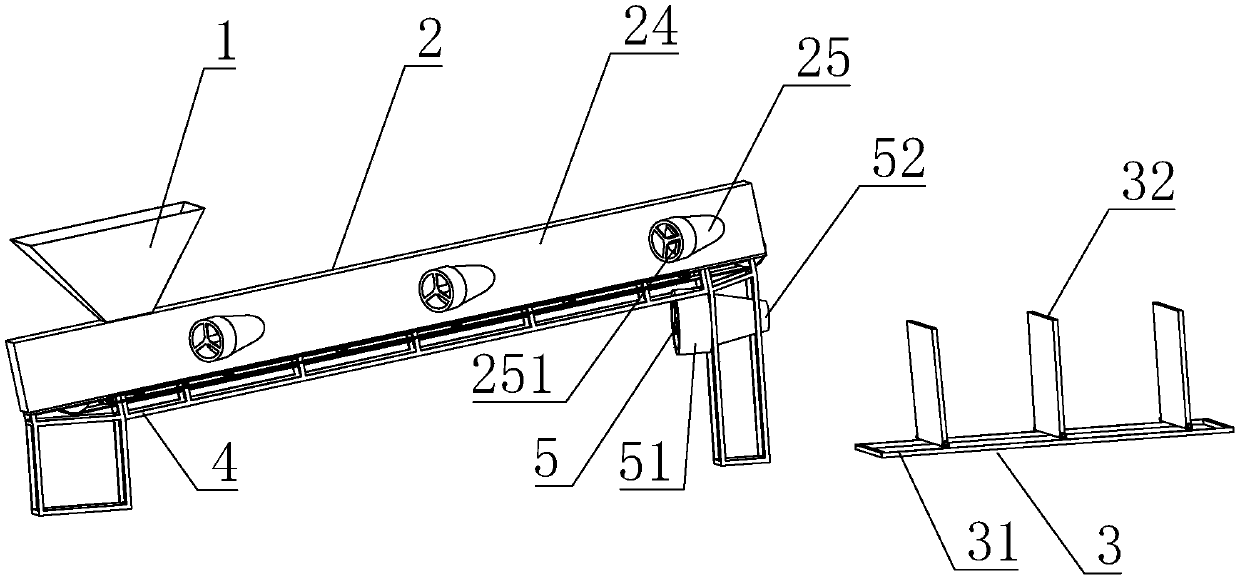

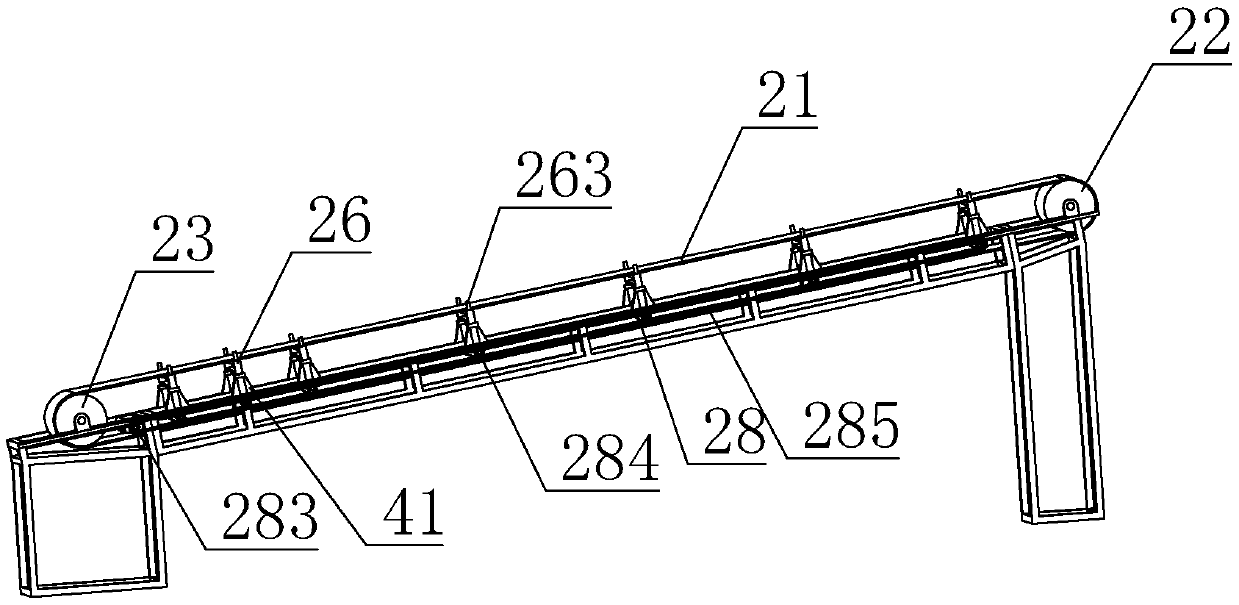

[0039] Example 1, please refer to Figure 1-7 , this embodiment discloses a garbage sorting and conveying equipment, including a feed bin 1, a sorting and conveying device 2, a material collecting device 3 and a frame 4, and the sorting and conveying device 2 includes a conveying part and a sorting part. The conveying part includes a conveyor belt 21 for carrying garbage and a drive wheel that drives the conveyor belt 21 to run. The conveyor belt 21 has a feed end and a discharge end and is tensioned on the two drive wheels. The drive wheel is rotatably mounted on At both ends of the frame 4, the driving wheel 22 is installed at the discharge end, and the driven wheel 23 is installed at the feeding end. The driving wheel 22 is connected to the output shaft of the first motor, and rotates under the drive of the motor to drive the conveyor belt to transport garbage. , the feed bin 1 is funnel-shaped with a large top and a small bottom, and is arranged above the feed end, and the...

Embodiment 2

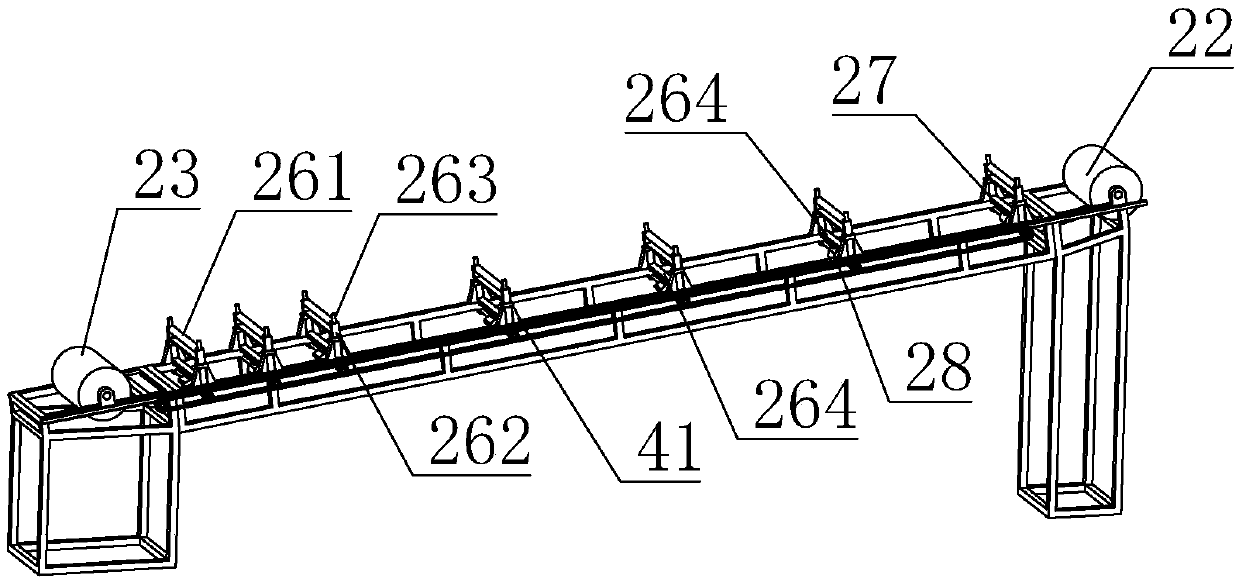

[0047] Example 2, please refer to Figure 6-10 , this embodiment discloses a garbage sorting and conveying equipment, including a feed bin 1, a sorting and conveying device 2, a material collecting device 3 and a frame 4, and the sorting and conveying device 2 includes a conveying part and a sorting part. The conveying part includes a conveyor belt 21 for carrying garbage and a drive wheel that drives the conveyor belt 21 to run. The conveyor belt 21 has a feed end and a discharge end and is tensioned on the two drive wheels. The drive wheel is rotatably mounted on At both ends of the frame 4, the driving wheel 22 is installed at the discharge end, and the driven wheel 23 is installed at the feeding end. The driving wheel 22 is connected to the output shaft of the first motor, and rotates under the drive of the motor to drive the conveyor belt to transport garbage. , the feed bin 1 is funnel-shaped with a large top and a small bottom, and is arranged below the feed end, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com